Test method for performance of high speed engine clutch

A technology of engine clutch and test method, which is applied in the direction of engine test, machine/structural component test, instrument, etc. It can solve the problems of high sensor price and difficult installation, and achieve the effect of high control precision and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

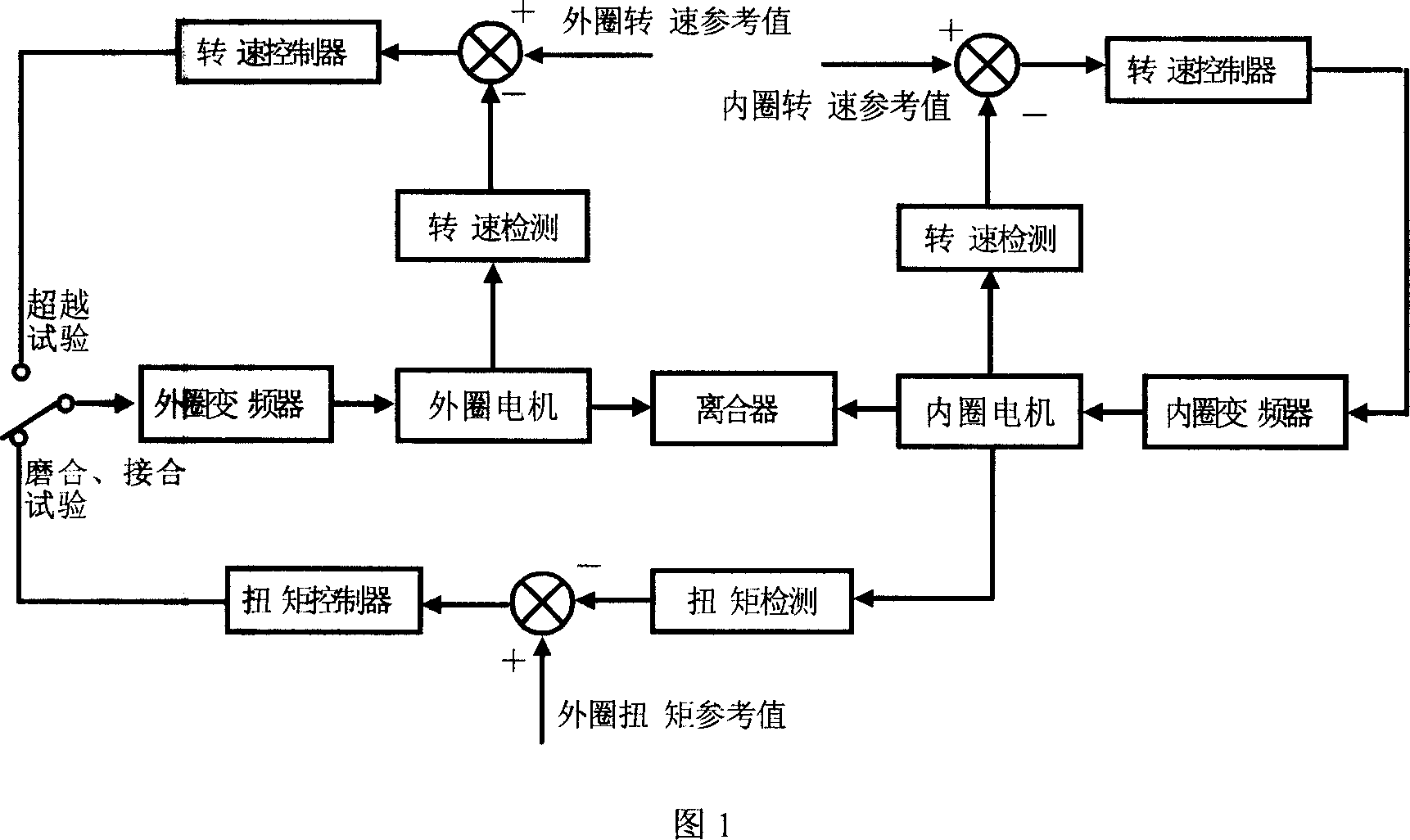

[0020] As shown in Figure 1, the inner ring motor and the outer ring motor are selected according to the speed and load of the test piece, and the corresponding inner ring inverter and outer ring inverter are selected according to the rated power and the rated power of the inner ring motor and outer ring motor Select the rated speed. The speed detection is measured by the pulse generated by the Hall sensor and the magnetic block installed on the motor shaft. First, the pulse is shaped and multiplied, and then converted into a voltage signal, which is converted into an industrial computer through AD conversion.

[0021] The transfer switch in Fig. 1 is controlled by software instructions. The torque control closed-loop works during the running-in and engagement tests, and the closed-loop control of the outer ring motor speed works during the overrunning test. The closed-loop control algorithm adopts improved PID control.

[0022] First switch the transfer switch to run-in and j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com