Re-separating process for non-ferrous metal tailings

A technology for non-ferrous metals and tailings, used in flotation, solid separation, etc., can solve the problem of metal tailings resources not being developed and utilized, and achieve the effects of small investment, convenient storage, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

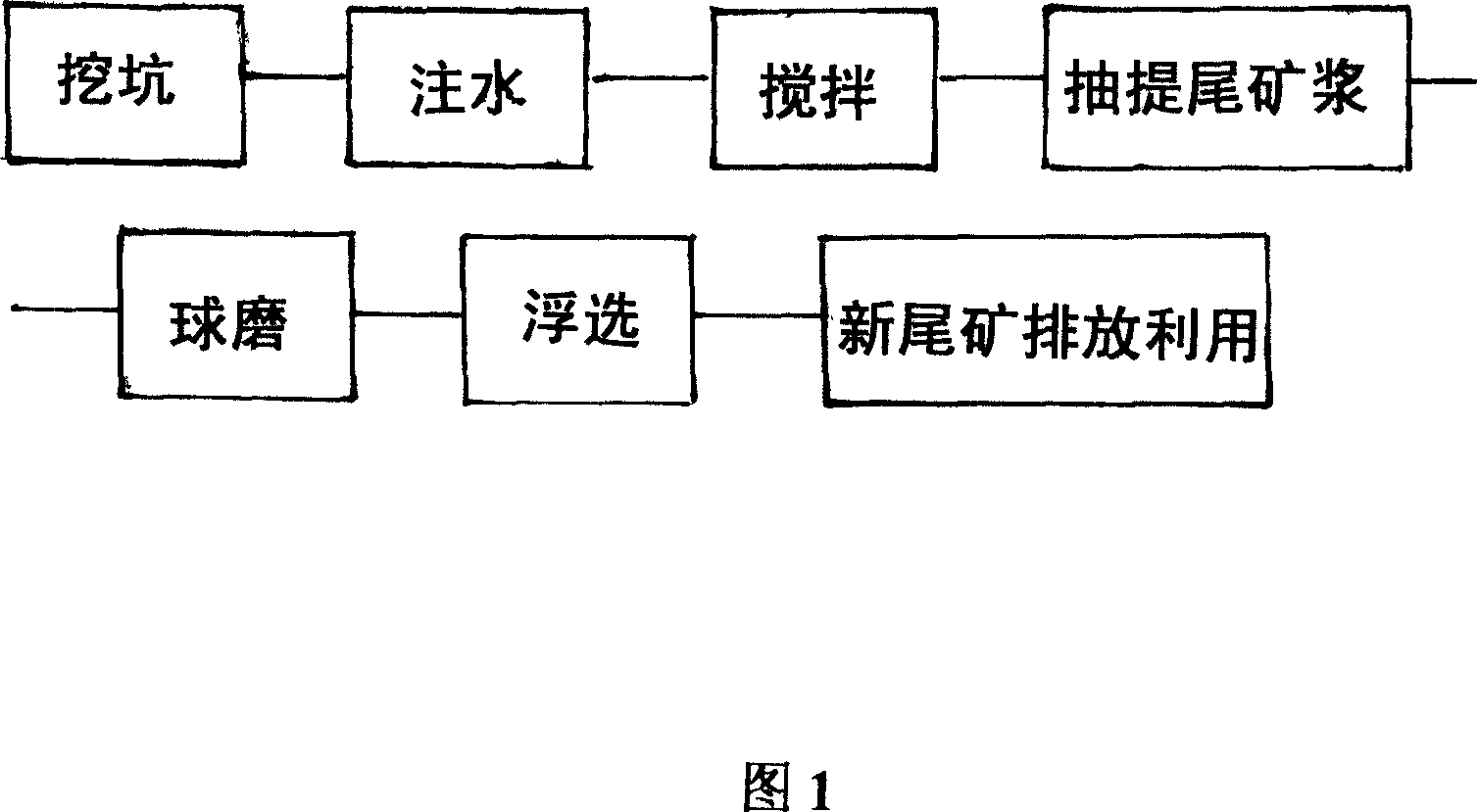

[0010] The specific steps of the technological process of the non-ferrous metal tailings recycling method of the present invention are further described in conjunction with the accompanying drawings and examples, and its features and advantages are clearer.

[0011] In the embodiment of the recycling method of non-ferrous metal tailings in the present invention, a shallow tailings pit with a diameter of 2m and a depth of 1.5m is excavated on the surface layer of the tailings pond that has been stacked for many years, and a support is fixed on the pit, and the shaft of the vertical mixer passes through The screw rod is erected on the bracket. As the tailings pit deepens, the height of the mixer can be adjusted. Install a 4″ mortar pump to inject water into the tailings pit. The amount of water injected can use the mixer to stir the tailings pit to make the tailings slurry. Use high-pressure water to wash the tailings, and use a mortar pump to extract the tailings slurry from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com