Method of regulating inclination angle of straightening roller

A technology of inclination angle and adjustment method, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low detection accuracy, difficult detection of the inclination angle of the straightening roller, and large space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

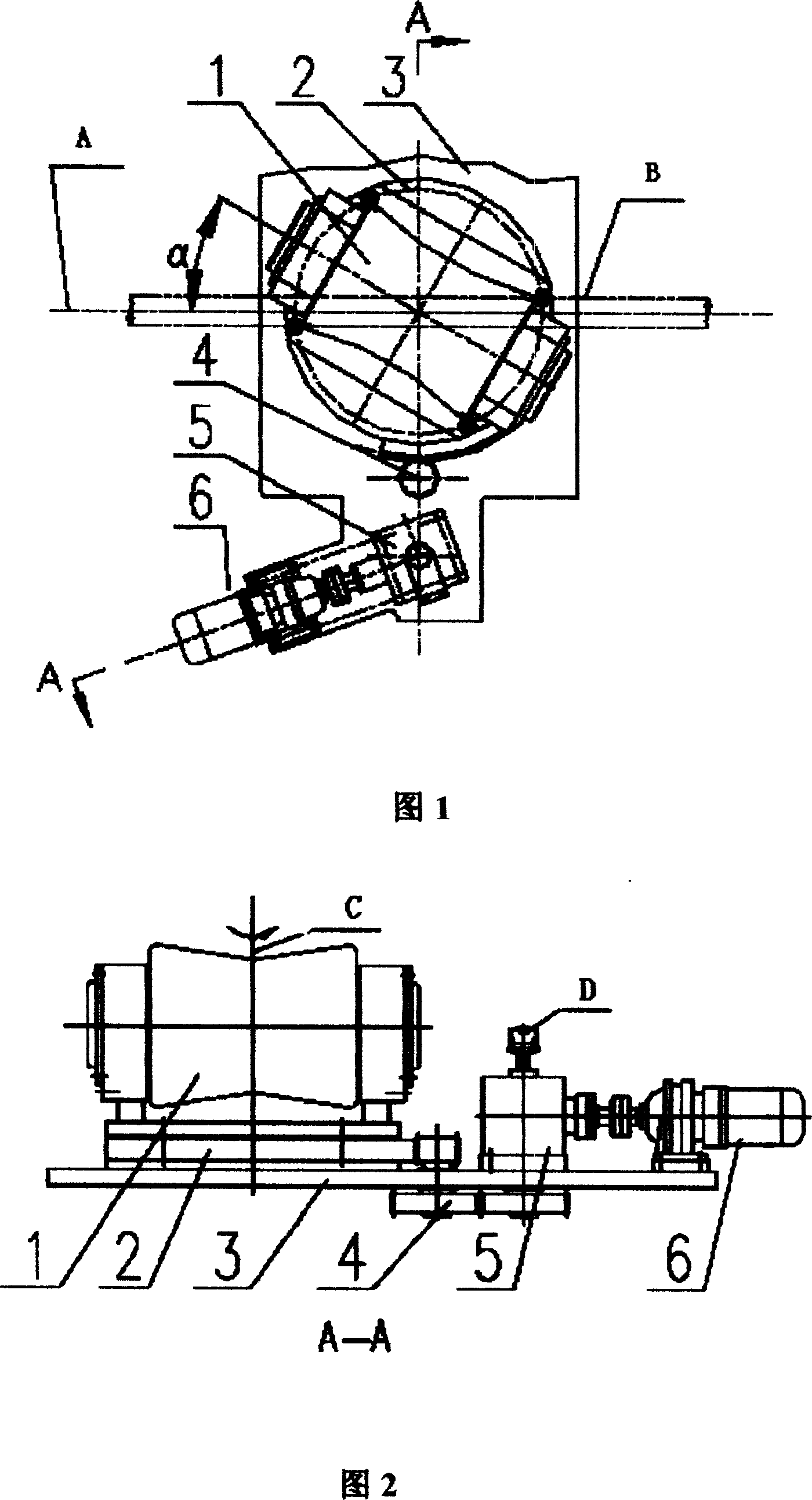

[0014] As shown in Figure 1, a bracket 2 is fixedly connected to the bottom of the straightening roller 1, and the bracket 2 has a ring gear turntable, and the ring gear of the bracket 2 is meshed with the output end of a gear train 4; The end is below the rack 3, and the output end is above the rack 3. The gear at the output is a pinion. The gear train 4 is a known gear transmission mechanism, and its input end is meshed with the gear on the output shaft of the reduction gear; side. The output end of the reduction gear is below the frame 3. It meshes with the input gear of the gear train 4 on the same side. A photoelectric sensing unit composed of an angle measuring sensor is connected to the shaft of the reduction gear. Generally speaking, the relative inclination angle between the straightening roller 1 and the centerline of the round material to be straightened, that is, the straightening centerline, is α, and the bracket 2 and the straightening roller 1 are fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com