Molten metal molding machine

A technology of molten metal and forming device, applied in the field of molten metal forming device, can solve the problem that the pressing speed of cylindrical metal material cannot be increased, and achieves the advantages of eliminating the possibility of oxidation of metal material, increasing the pressing speed, and inhibiting oxidation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

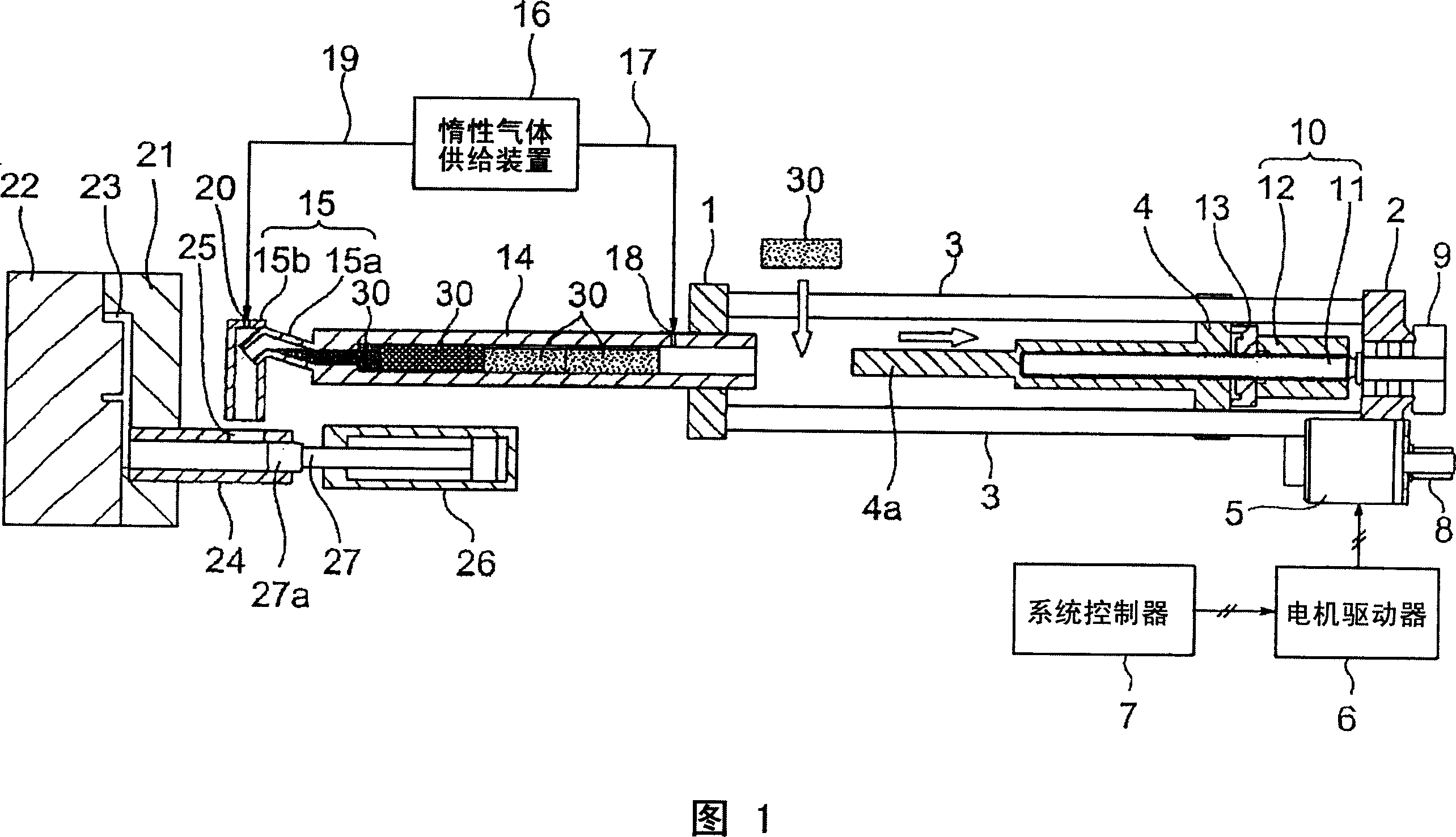

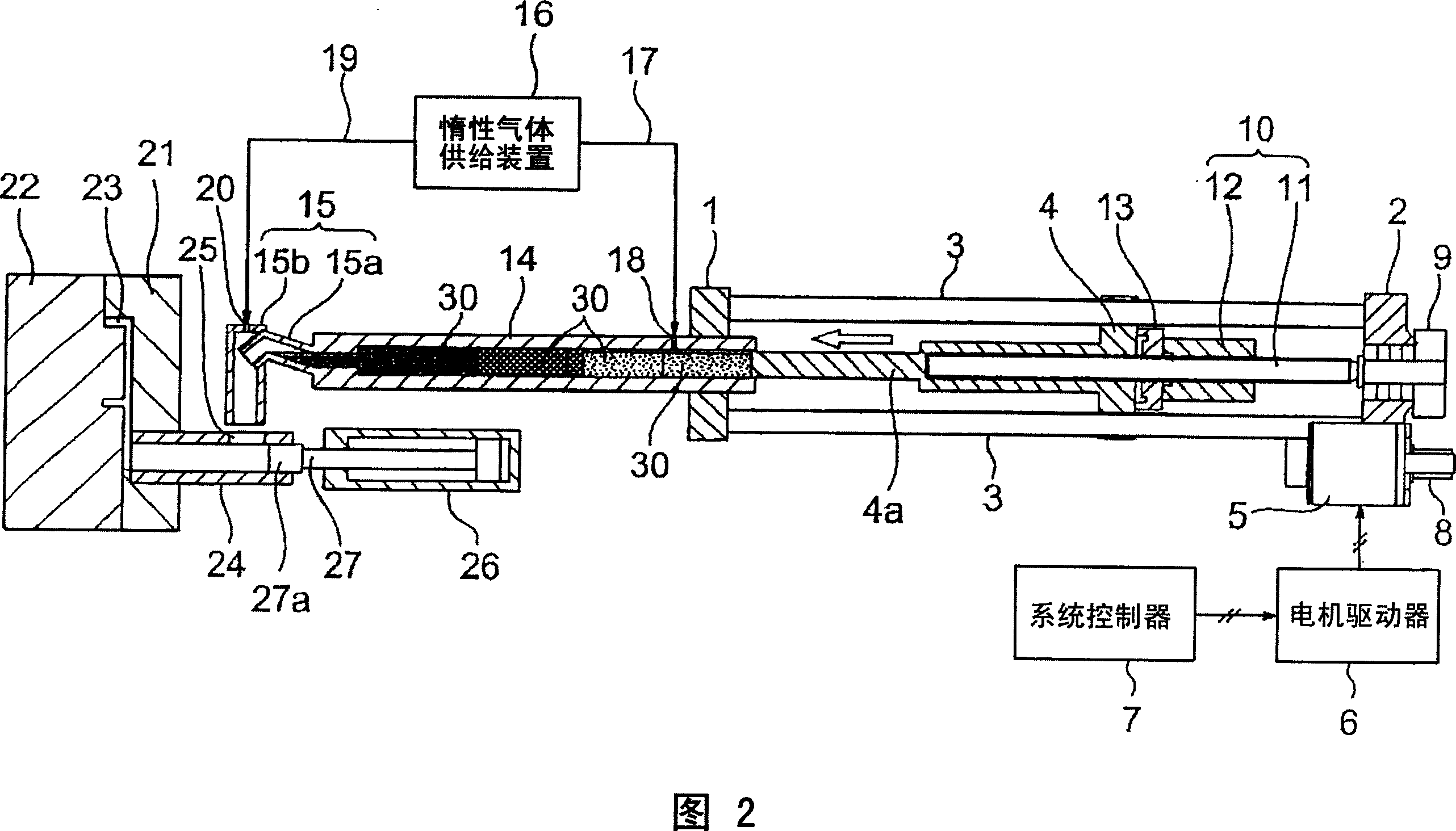

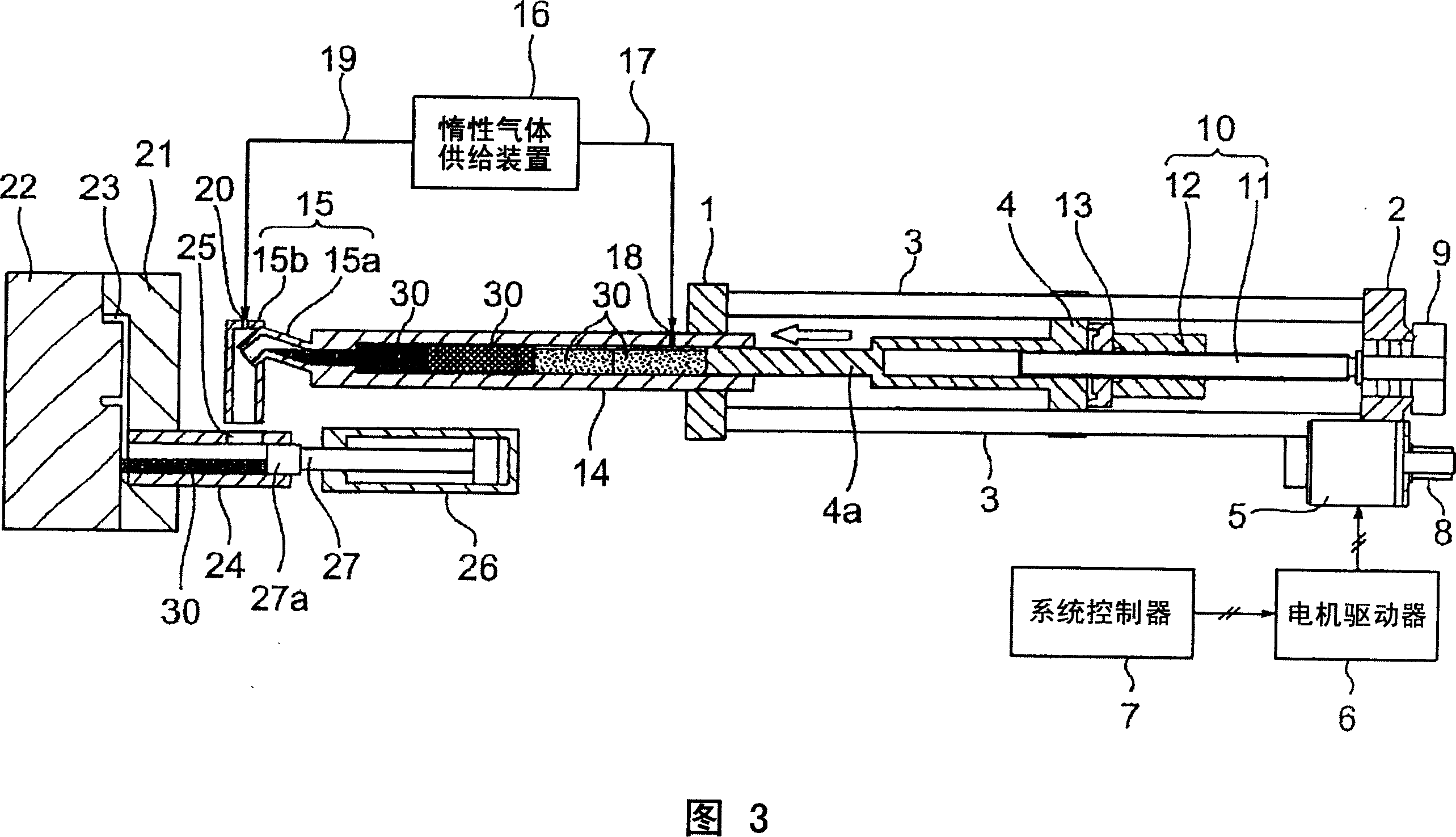

[0033] Embodiments of the present invention will be described below using the drawings. FIGS. 1 to 6 relate to a molten metal forming apparatus according to one embodiment of the present invention (hereinafter referred to as the present embodiment), and FIGS. 1 to 4 are explanatory diagrams schematically showing main parts of the molten metal forming apparatus according to this embodiment.

[0034] In Fig. 1 to Fig. 4, 1 is the first holding plate that can be set forward and backward on the unillustrated guide rail member for the fusion system unit, and 2 is also on the unillustrated guide rail member for the fusion system unit The second holding plate that can be set forward and backward and opposite to the first holding plate, 3 is a plurality of connecting shafts that integrally connect the first holding plate 1 and the second holding plate 2, and 4 is used in the melting system unit not shown The guide rail member is set forwardly and backwardly (or is inserted and guided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com