Thermomagnetic particle dynamic drying device based on plastic particles and application method

A technology of plastic particles and drying equipment, which is applied in the field of plastic production, can solve the problems of high heat, oxidation, and insufficient drying of plastic particles, and achieve the effect of promoting continuous deformation and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

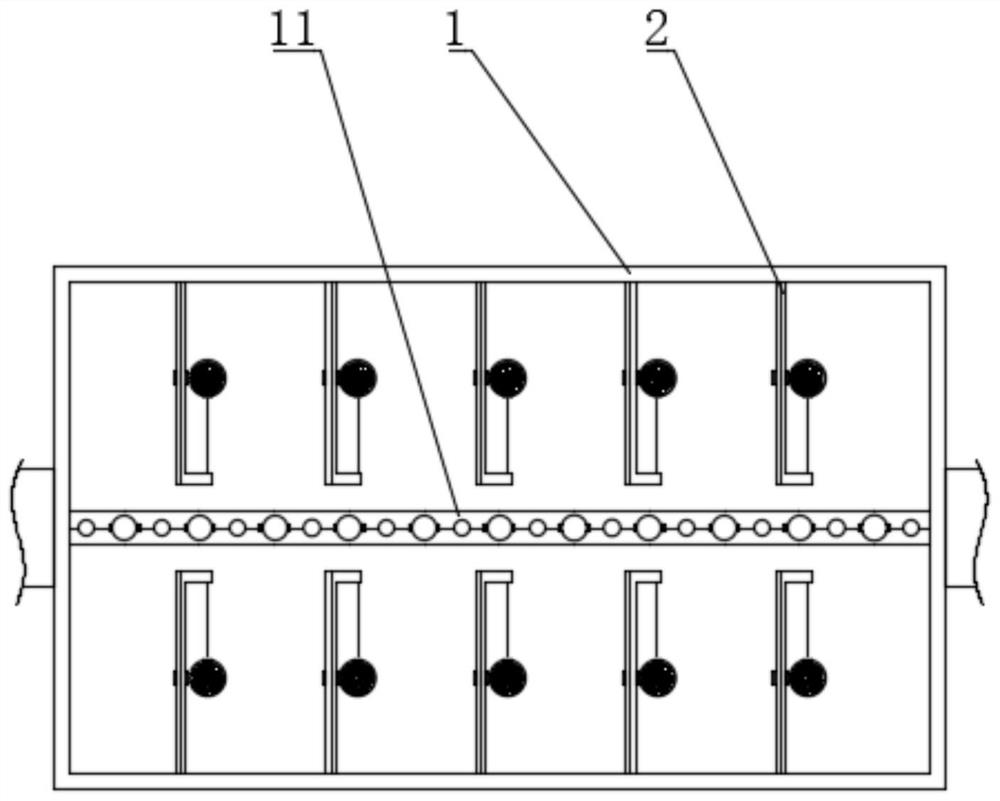

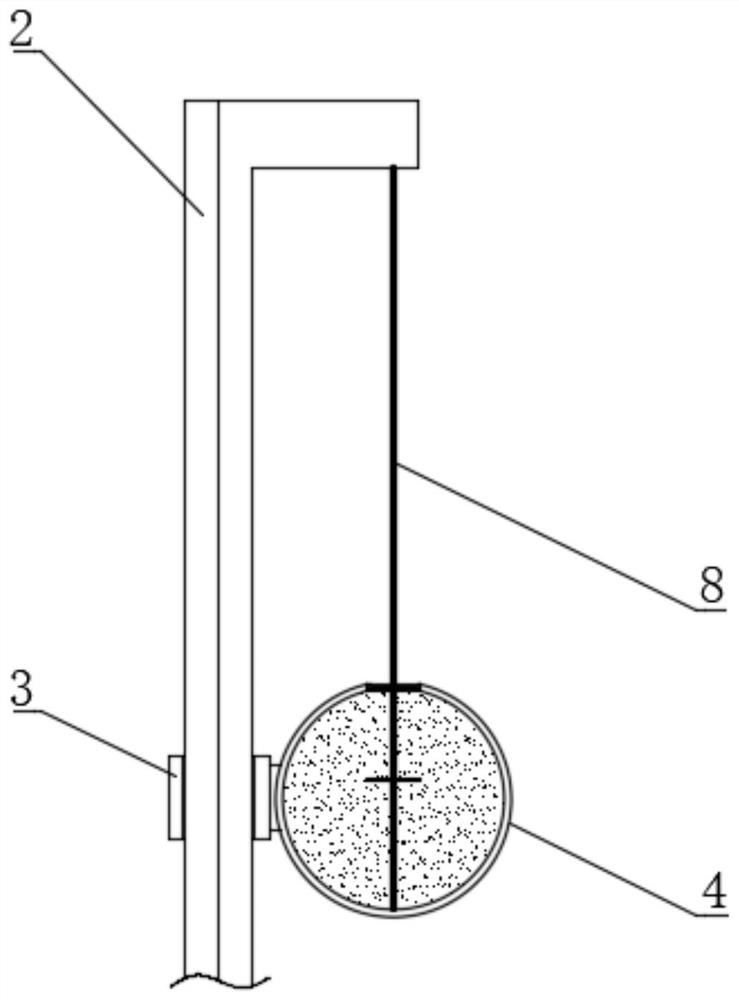

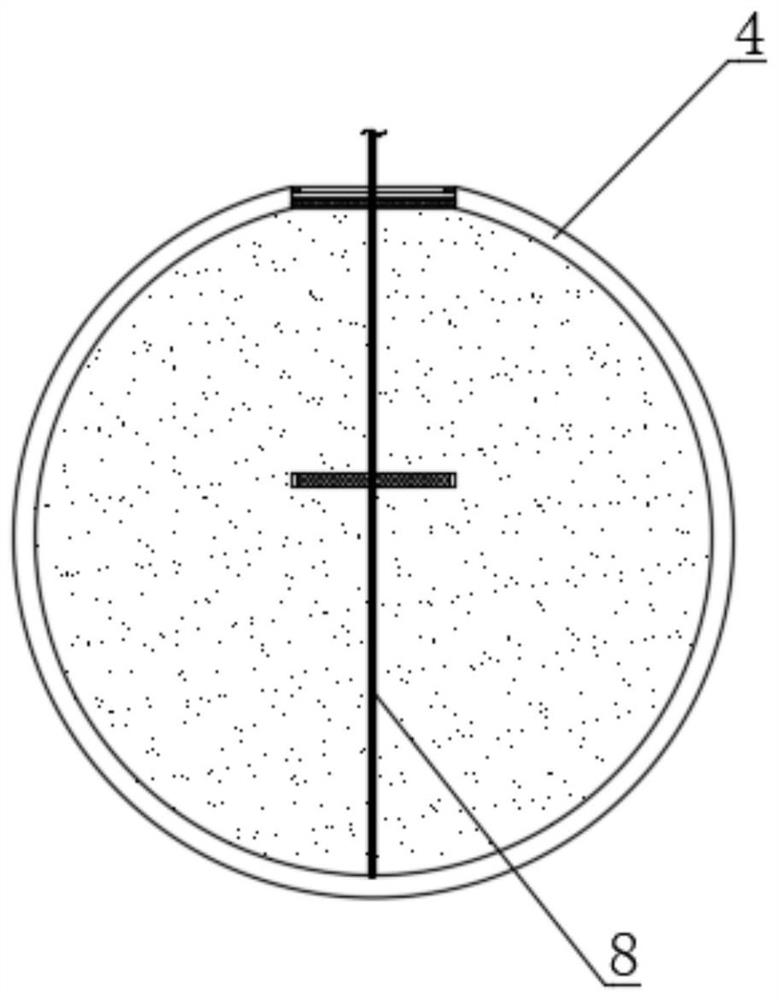

[0044] see Figure 1-5 , a thermomagnetic particle dynamic drying device based on plastic particles, including a modified drying cylinder 1, the modified drying cylinder 1 is usually connected with the power output end of the servo motor in actual use, with the help of the motor Rotate to promote the drying of the plastic particles in it more fully. The annular inner wall of the modified drying cylinder 1 is fixedly connected with a plurality of evenly distributed built-in L-shaped struts 2, and the outer ends of the built-in L-shaped struts 2 are slidingly connected with movable sliding sleeves 3. The outer end of the movable sliding sleeve 3 is fixedly connected with a centrifugal ball 4, the upper end of the centrifugal ball 4 is drilled with a release hole 5, and the inner wall of the release hole 5 is fixedly connected with a pair of rubber seals 6 that are pressed against each other, and the release hole 5 The inner wall is fixedly connected with the first filter screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com