Semi-finished rubber cutting machine

A technology for cutting machines and semi-finished products, which is applied in object supply, metal processing, pile separation, etc. It can solve the problems of inaccurate length of rubber strips, single cutting specifications, high labor intensity, etc., and achieves compact structure, high production efficiency, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

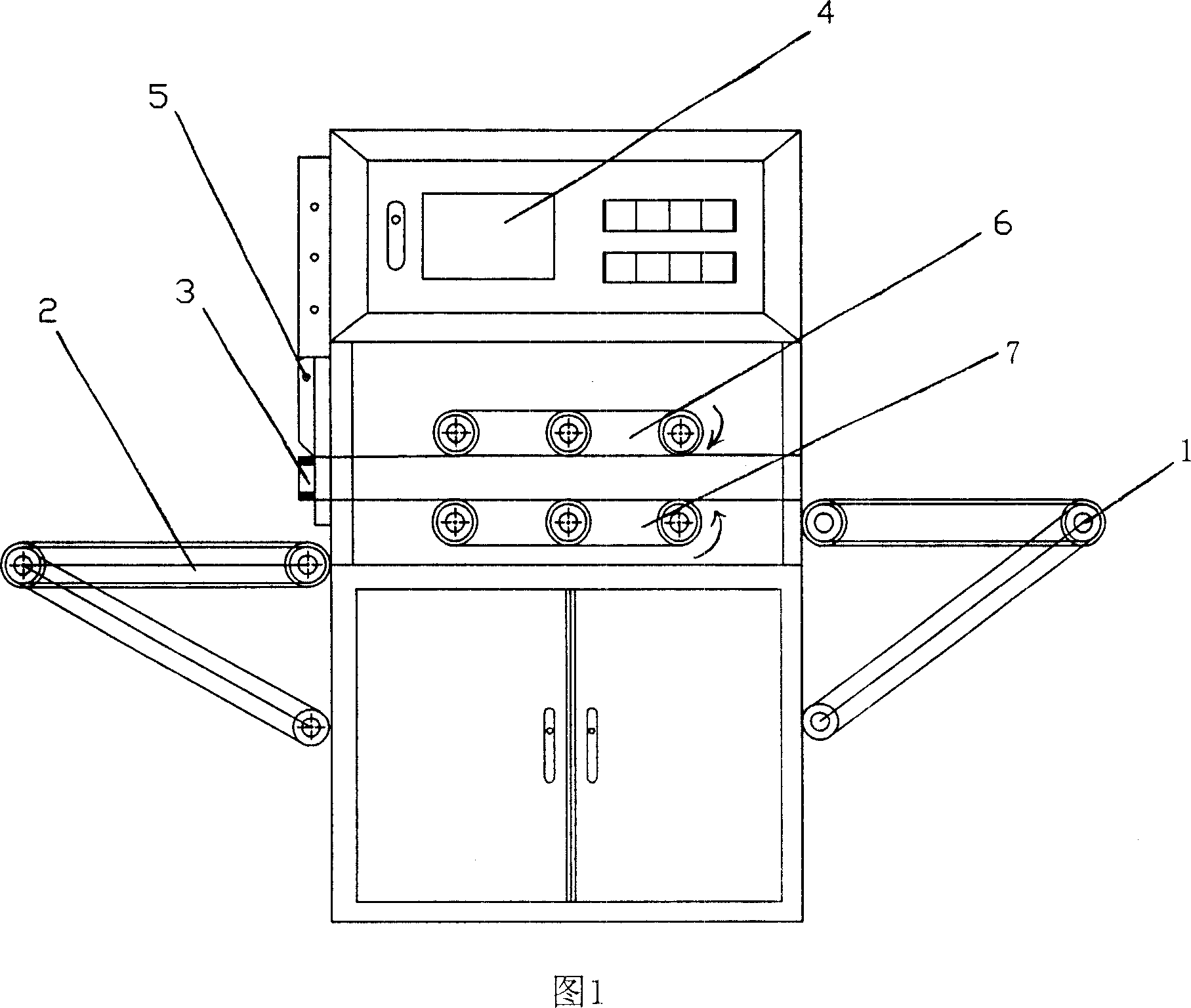

[0020] As shown in Figure 1, the semi-finished rubber cutting machine includes a machine base, one end of the machine base is provided with a feed end 1, the other end is provided with a discharge end 2, and a shearing mechanism 3 is provided above the discharge end 2. Mechanism 3 is driven by a power mechanism and a connecting mechanism. Between the feed end 1 and the discharge end 2, an upper clamping belt 6 and a lower clamping belt 7 matching the upper and lower positions are arranged, and a gap corresponding to the shearing mechanism 3 is left between the upper clamping belt 6 and the lower clamping belt 7. The corresponding gap is driven by the power mechanism to move at the same speed. The semi-finished raw material is introduced into the gap between the upper clamping belt 6 and the lower clamping belt 7 from the feed end 1, and moves toward the discharge end 2. Driven by the clamping of the upper clamping belt 6 and the lower clamping belt 7, it enters the shearing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com