Liquid distributor and liquid collector for chromatography columns

A liquid distributor and liquid collector technology, which is applied in the direction of solid adsorbent liquid separation, instrument, material separation, etc., can solve the problems of simultaneous satisfaction and the design of residence time has not been disclosed, and achieve the effect of improving the separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

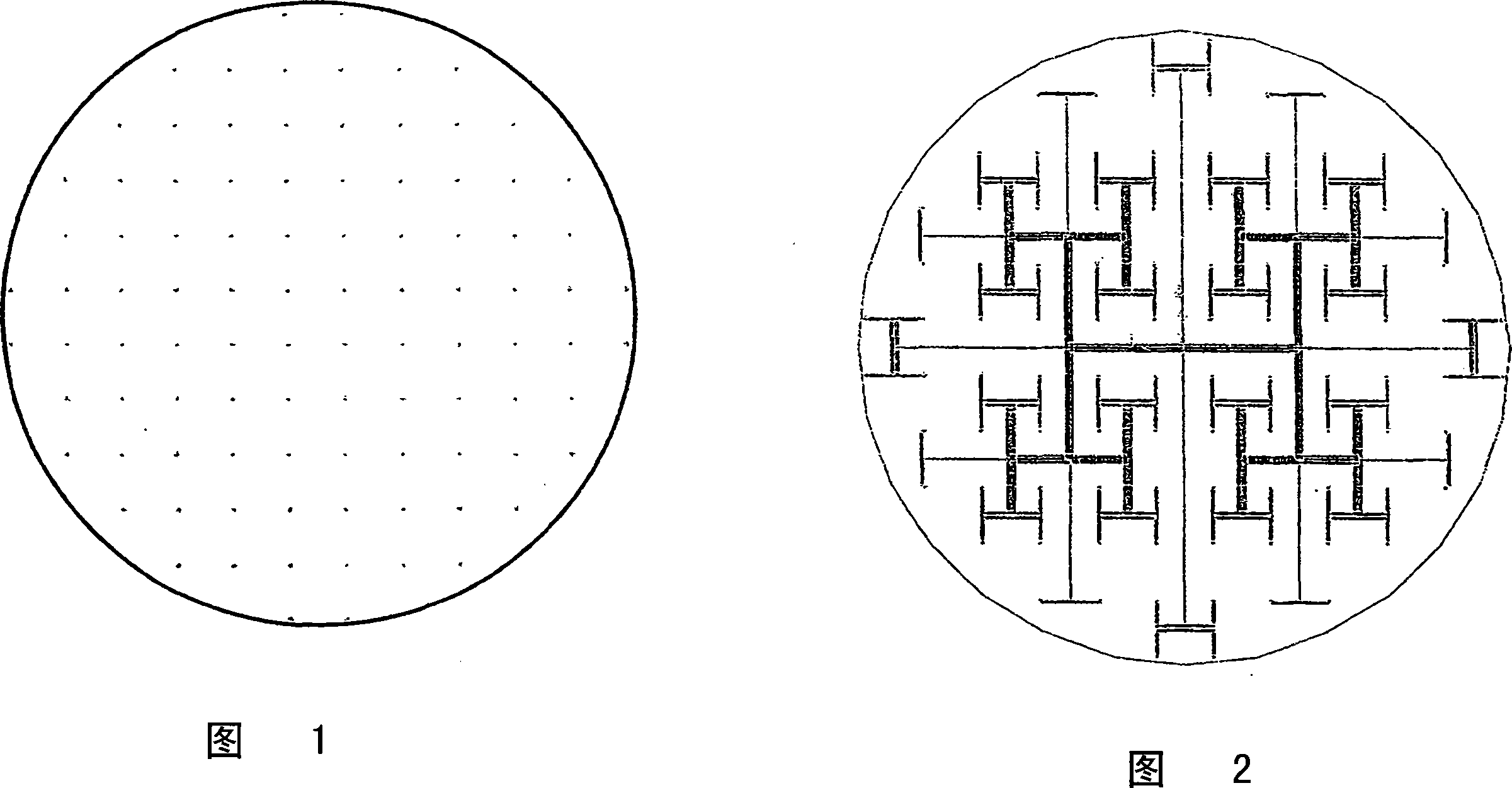

[0030] FIG. 1 shows the side of the liquid distributor or liquid collector facing the cylindrical packing. 96 equidistant openings can be seen, which are evenly arranged on the circular flow cross-section. These openings are circular.

[0031] FIG. 2 shows the side of the liquid distributor or liquid collector with a centrally located inlet or outlet facing away from the cylindrical packing. Symmetrical and asymmetrical T-distributor shaped flow channels are shown here. The openings to the cylindrical packing are in each case in the tip of the T.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com