Filling device for producing ceramic wall-floor tiles

A technology for wall and floor tiles and ceramic powder, which is applied to supply devices, ceramic molding machines, manufacturing tools, etc., can solve the problems that are difficult to control and cannot satisfy the colorful tones and single colors of natural stone, and achieve simple structure and colorful colors. , layered effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

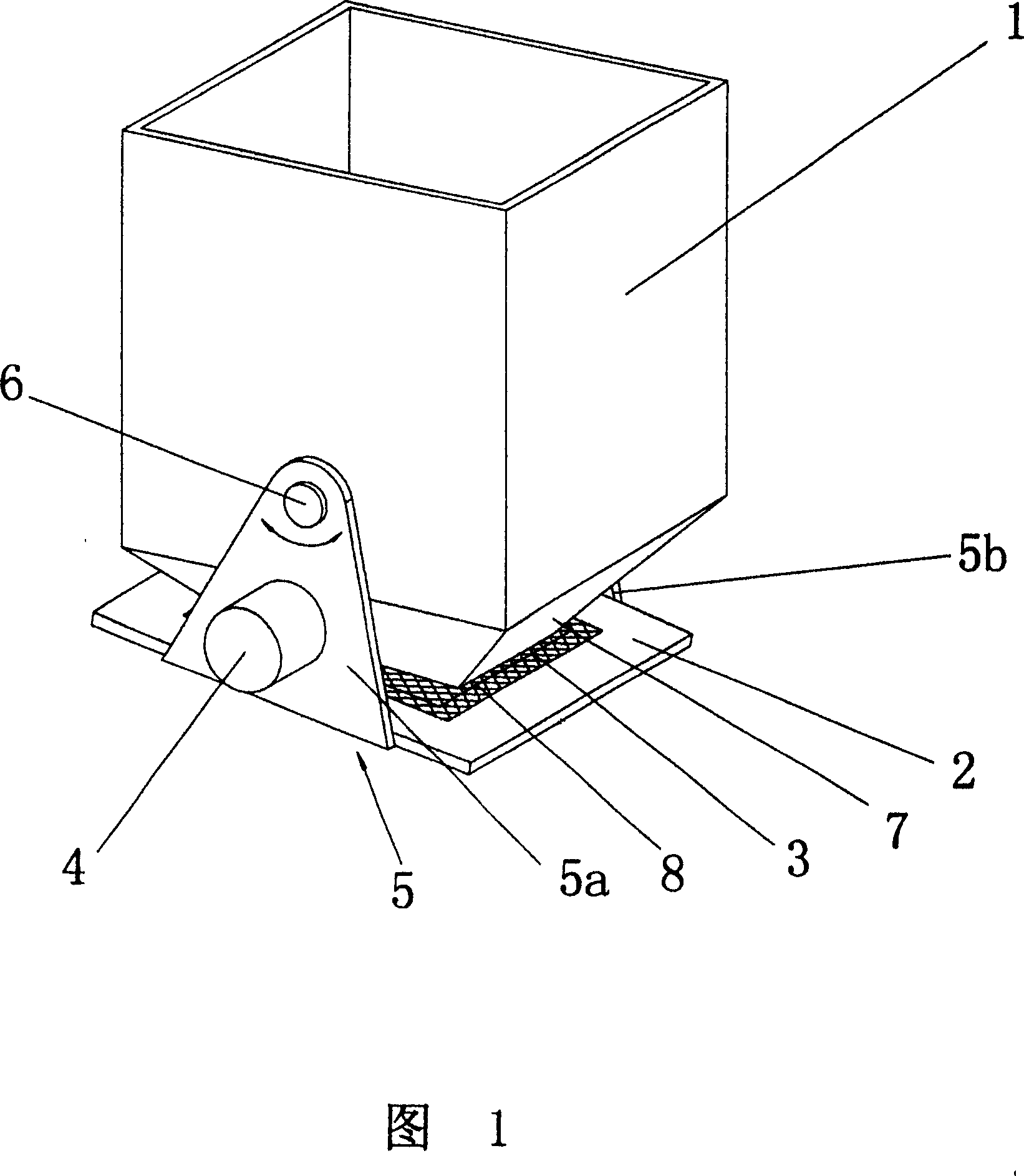

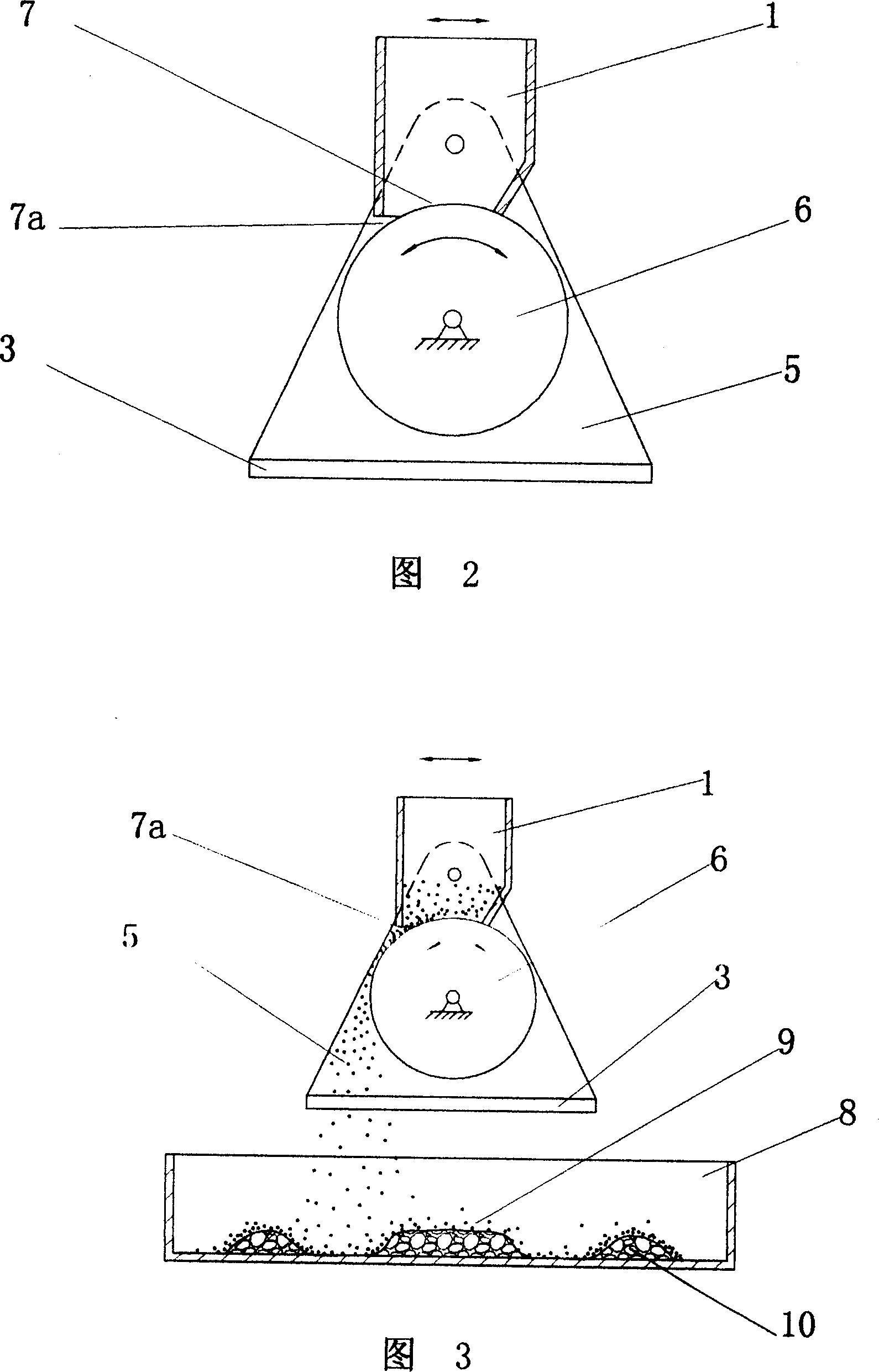

[0011] A filling device for the production of ceramic wall and floor tiles, as shown in Figure 1, includes a storage hopper 1, and a screen 3 with a grid hole size slightly larger than the particle size of ceramic powder is provided at the outlet 7 below the storage hopper 1 , the two sides of the storage hopper 1 are equipped with vibrating devices 4 that can make the ceramic powder in the storage hopper 1 pass through the screen 3 and be floating and sprinkled.

[0012] The more specific structure of the present invention is, is made up of storage hopper 1, swing frame 5, screen frame 2, screen cloth 3 and vibrating device 4. The bottom of the storage hopper 1 is funnel-shaped with a small bottom and a big top. One end of the left swing frame 5a and the right swing frame 5b is connected with the hinge 6 of the storage hopper, and the other end is fixedly connected with the screen frame 2. The screen 3 is located in the storage hopper. The bottom of the outlet 7 below the hop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com