Control of a printing press using a torsion model

A printing machine and model technology, applied in the direction of rotary printing machine, general parts of printing machinery, printing machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

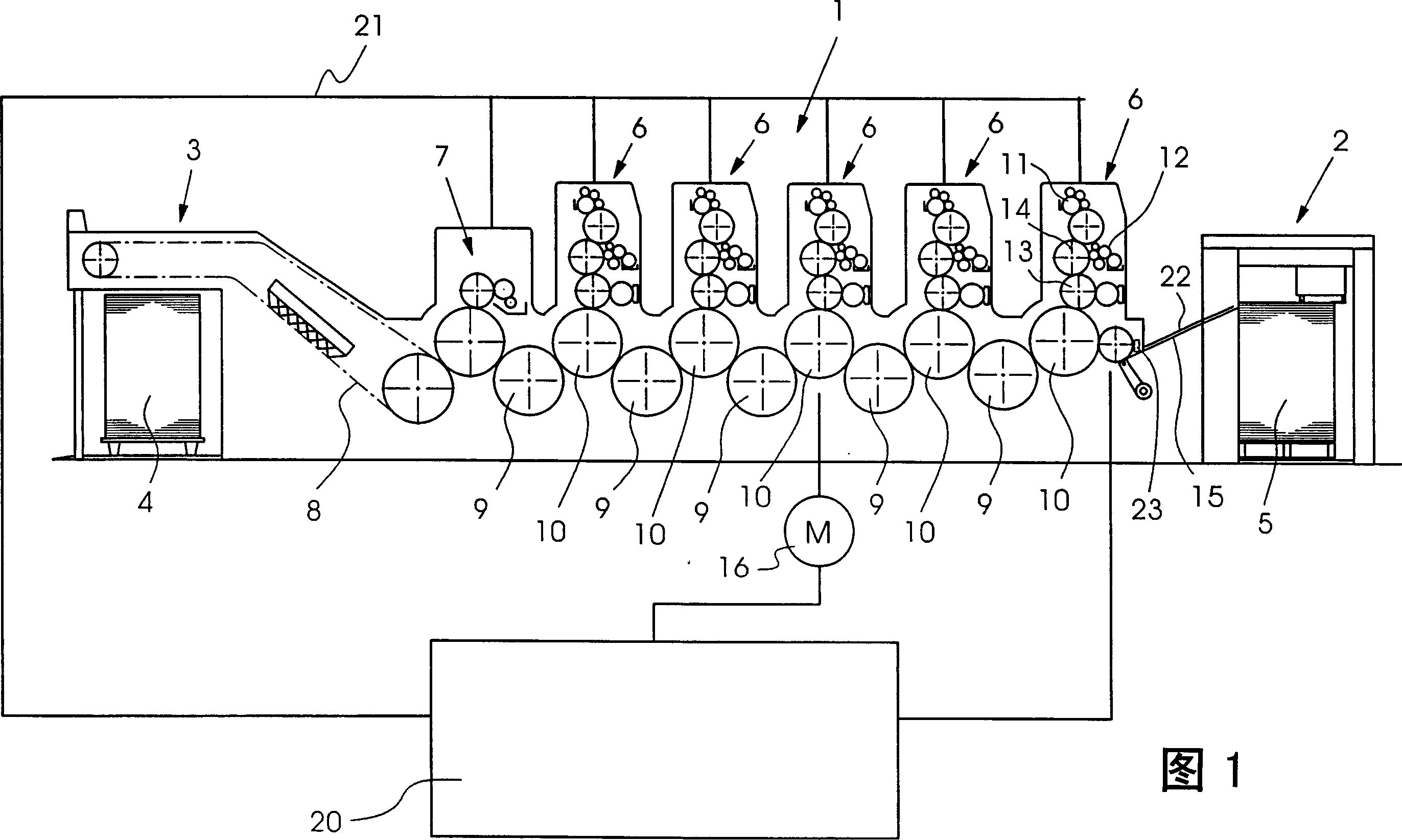

[0025] FIG. 1 shows a printing press 1 which processes sheet-like printing materials 22 in offset web printing. The printing press 1 has five printing units 6 and one coating unit 7 . The first four printing units 6 are used here to apply inks of the four primary colors yellow, red, blue and black in front printing, while the fifth printing unit 6 is filled with spot color inks such as silver, gold or similar. However, the inks used in the printing unit 6 are completely irrelevant for the functioning of the invention. Following the fifth printing unit 6 , the printed sheet 22 is provided with a coating in the coating unit 7 . The printed sheets 22 produced in the glazing unit 7 are gripped by means of the gripper bridges in the delivery conveyor chain 8 and deposited on the delivery pile 4 in the delivery unit 3 . If the delivery pile 4 has reached its maximum height, it is removed and reprocessed. On the side of the printing press 1 opposite the delivery is a feeder 2 whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com