Vertical high-concentration paste mill

A high-concentration, refiner technology, applied in pulp beating/refining methods, textiles and papermaking, fiber raw material processing, etc., can solve the problems of poor operation stability, low adjustment accuracy, low work efficiency, etc. , The effect of good operation stability and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

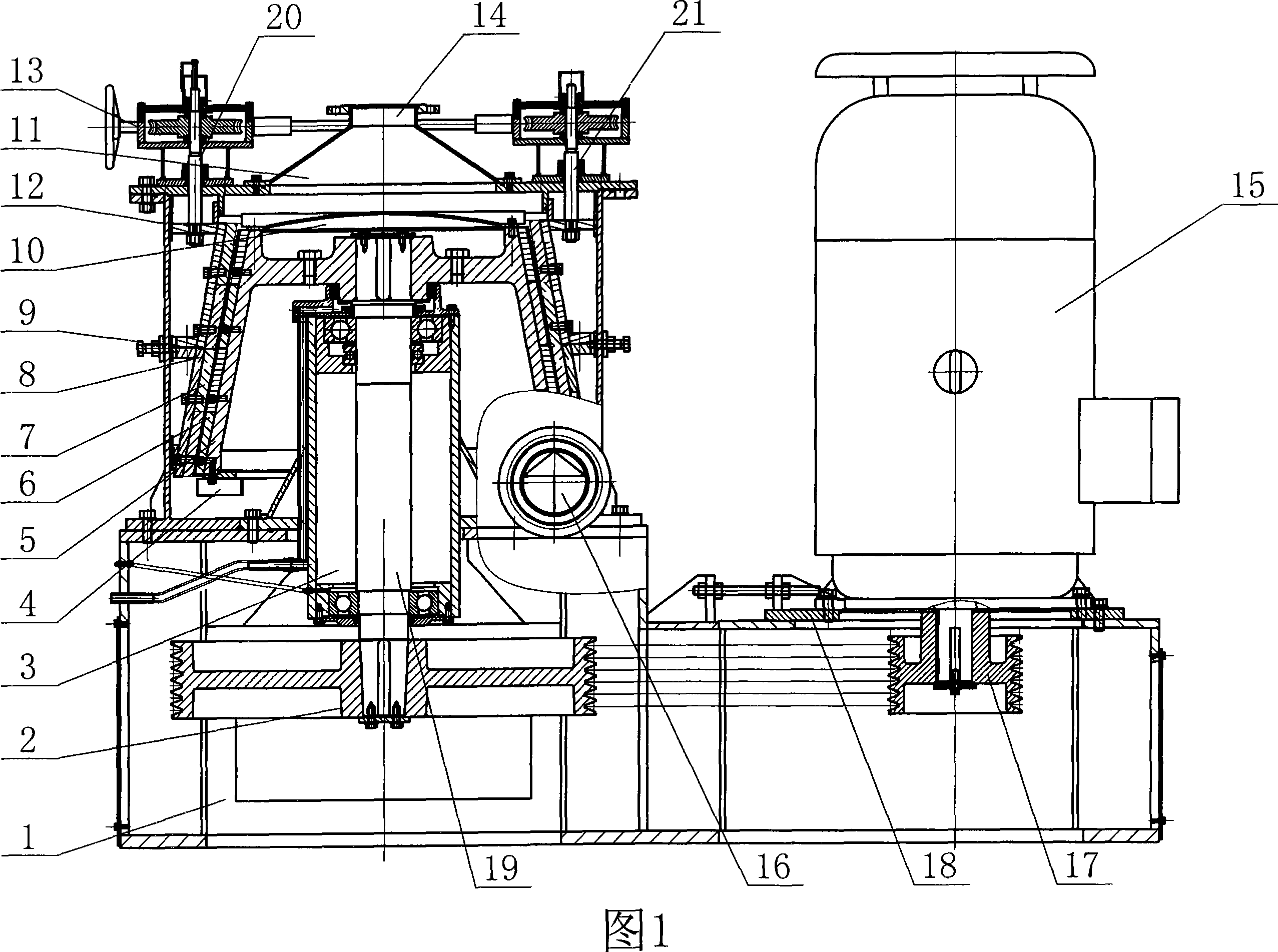

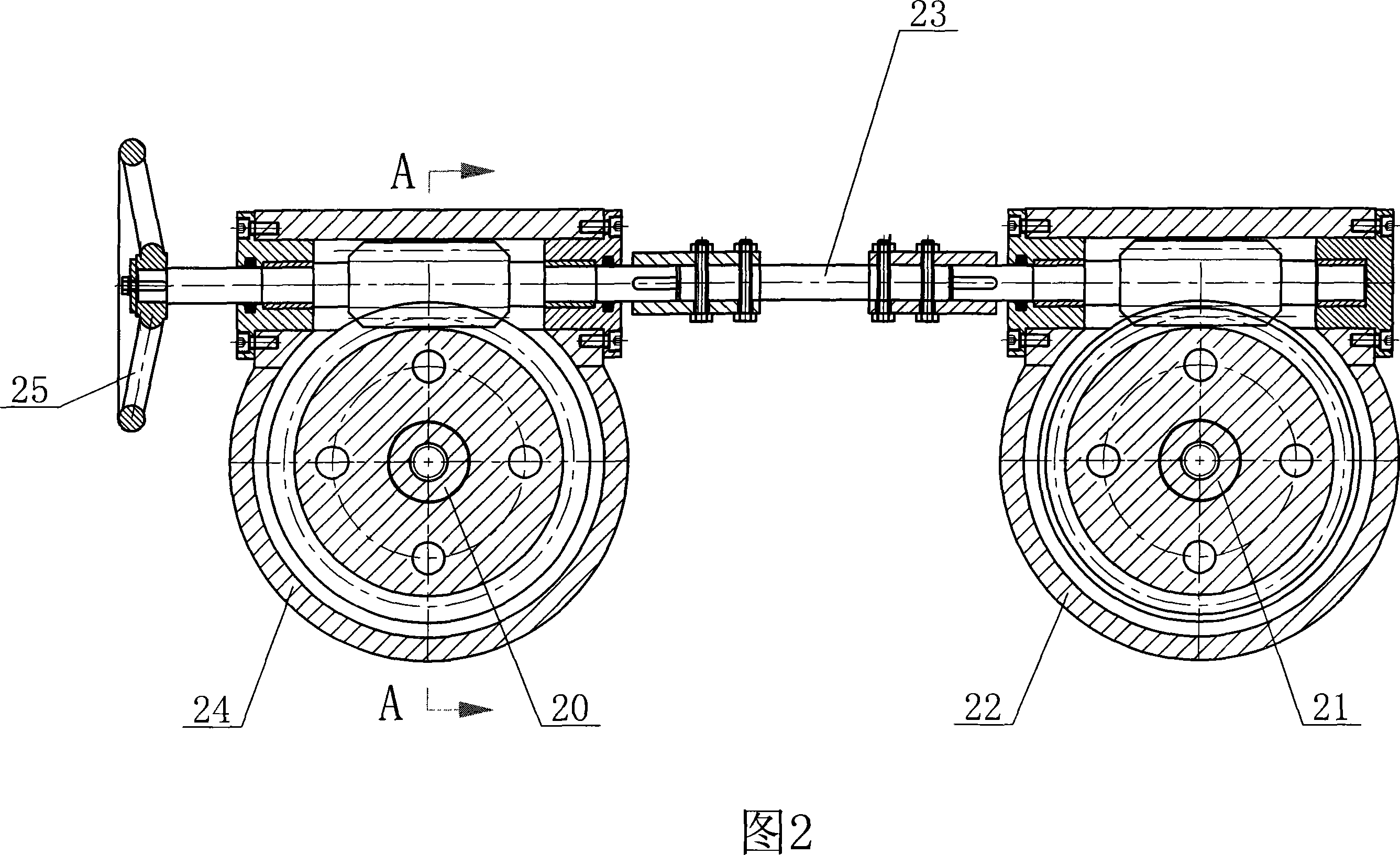

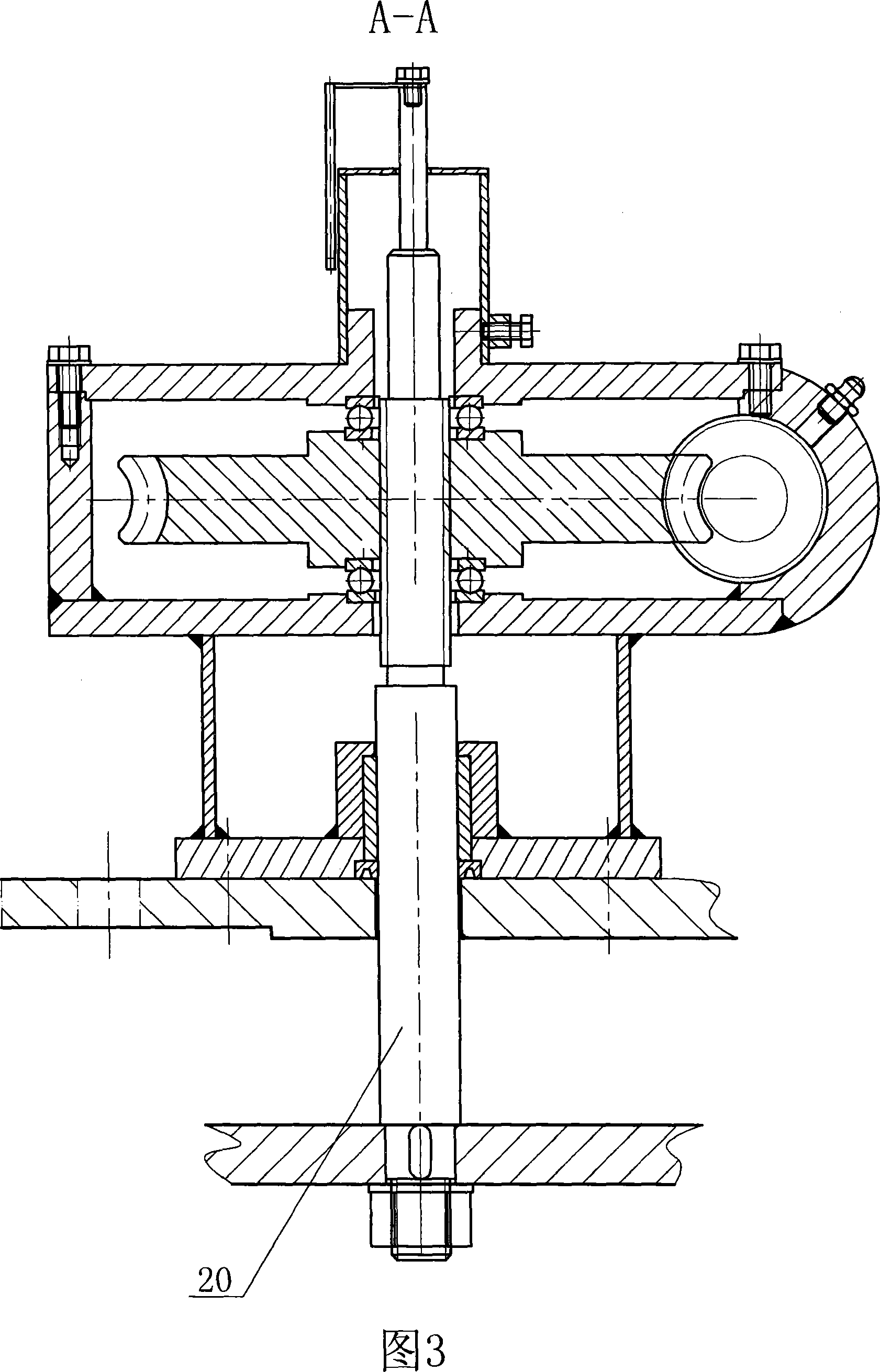

[0007] The present invention will be further described with reference to accompanying drawing and embodiment:

[0008] 12 among the figure is housing, and main shaft 19 is installed in the middle part of housing 12, and large belt pulley 2 is installed at the bottom end of main shaft 19, and large belt pulley 2 is connected with motor 15 output shafts by belt and small belt pulley 17, and the axis of motor 15 output shafts and main shaft 19 axes Parallel, the upper end of the main shaft 19 is connected with the conical rotor core 5, the outer circumference of the conical rotor core 5 is equipped with a rotor sleeve 6, the outer wall of the rotor sleeve 6 is provided with rotating teeth, the housing 12 is connected with the conical stator 8, and the conical stator 8 is installed with a stator The ring gear 7 and fixed teeth are arranged on the inner wall of the fixed ring gear 7, and the locking device 9 is installed between the outer wall of the conical stator 8 and the housing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com