Pump and pumping system

A pump casing and electronic substrate technology, applied in the field of pumps and pump systems, can solve the problems of high-density installation requirements of electronic components that cannot meet the miniaturization requirements of information equipment, increase the area of electronic substrates, abnormal operation and failure, etc. The effect of miniaturization, improvement of installation efficiency, prevention of abnormal operation and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Next, the best mode for carrying out the present invention will be described with reference to the drawings.

[0049] [Mechanical structure]

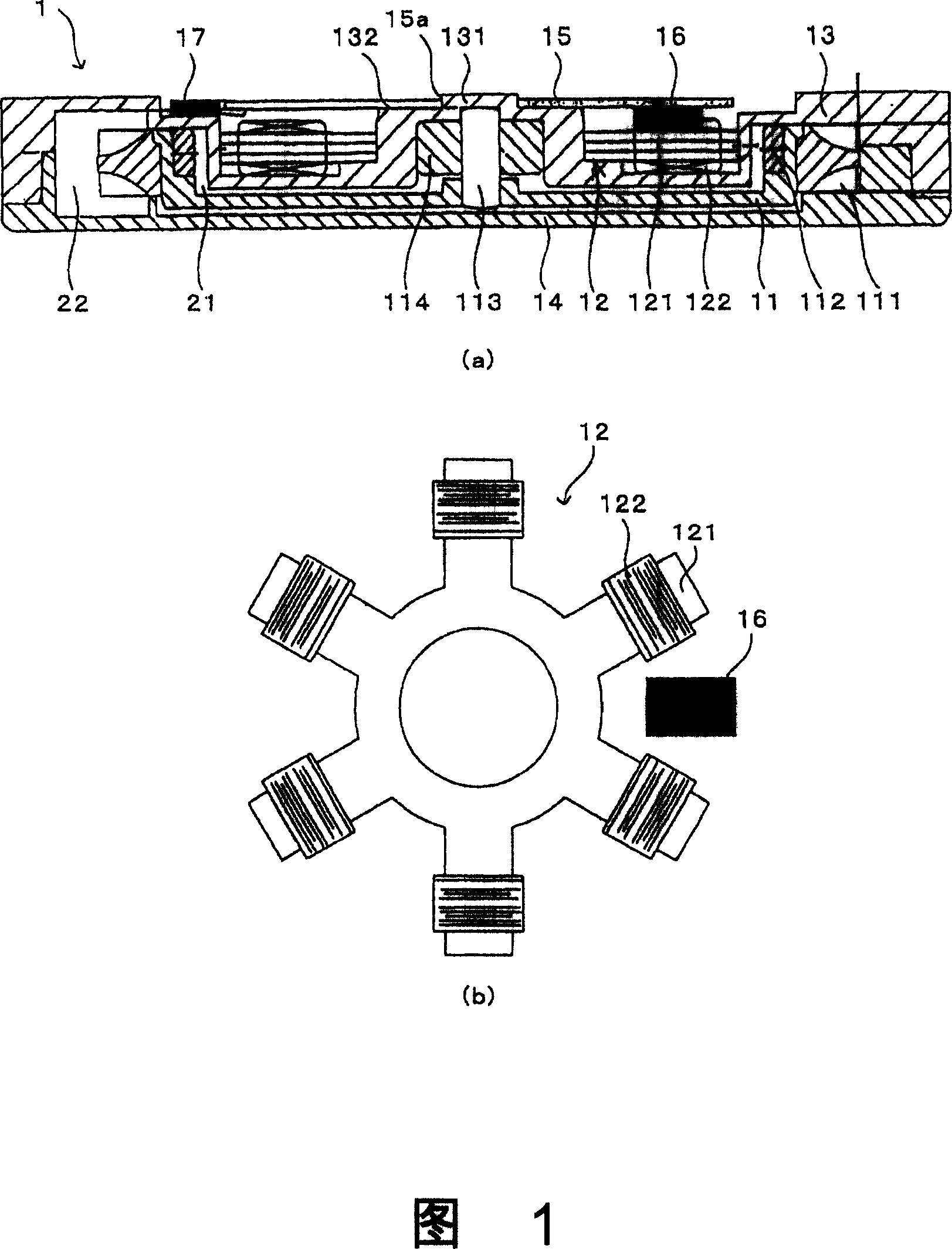

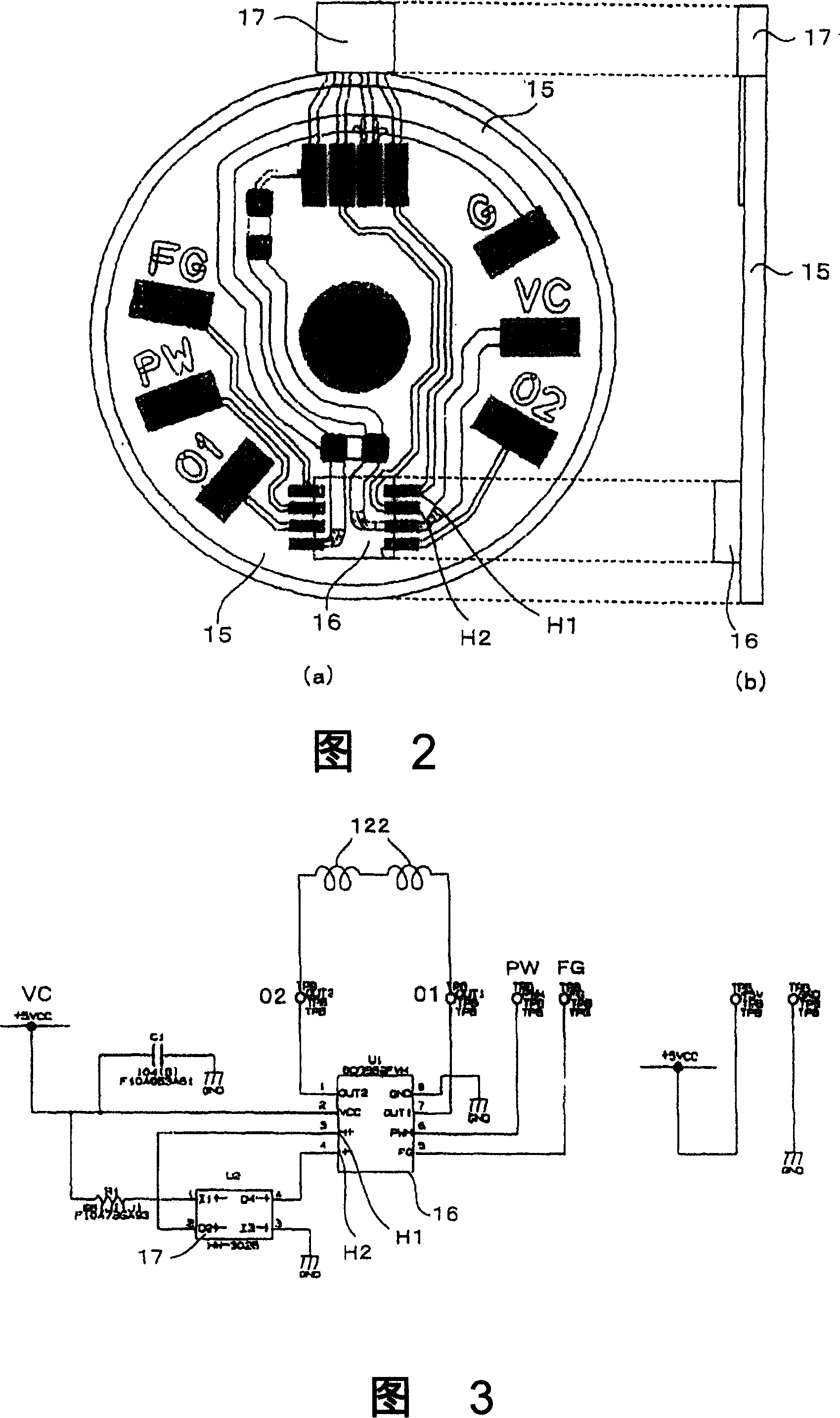

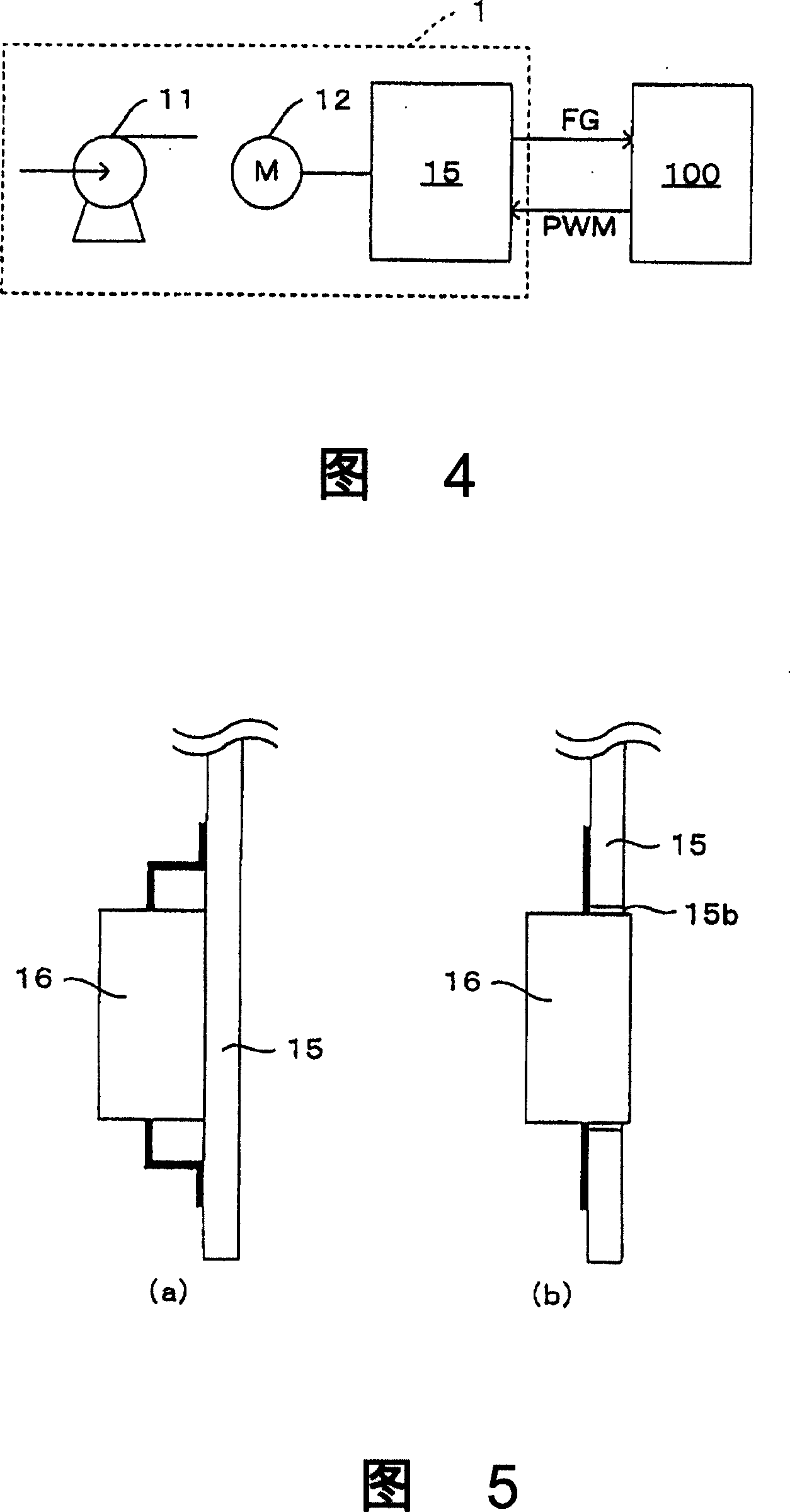

[0050] Fig. 1 is a mechanical configuration diagram showing a pump 1 according to an embodiment of the present invention. In particular, FIG. 1( a ) shows a side sectional view of the pump 1 , and FIG. 1( b ) is a schematic plan view showing the positional relationship between the stator 12 and the drive IC 16 . In addition, for convenience of explanation, Fig. 1(a) is upside down.

[0051]In FIG. 1( a ), the pump 1 according to this embodiment is mainly composed of an impeller 11 , a stator 12 , a pump casing 13 , and a bottom plate 14 .

[0052] A plurality of blades 111 are formed on the outer periphery of the impeller 11 , and the rotation of the impeller 11 induces eddy currents around the blades 111 . In addition, by performing waterproof processing on the surface of the blade 111, it is possible to start the rotation sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com