Method for preparing power-micro structure LED tube core utilizing flip chip technology

A light-emitting diode, power-type technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of poor uniformity of current expansion, sacrifice of active area, and inability to realize n-electrode interconnection, etc., and achieve the effect of improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

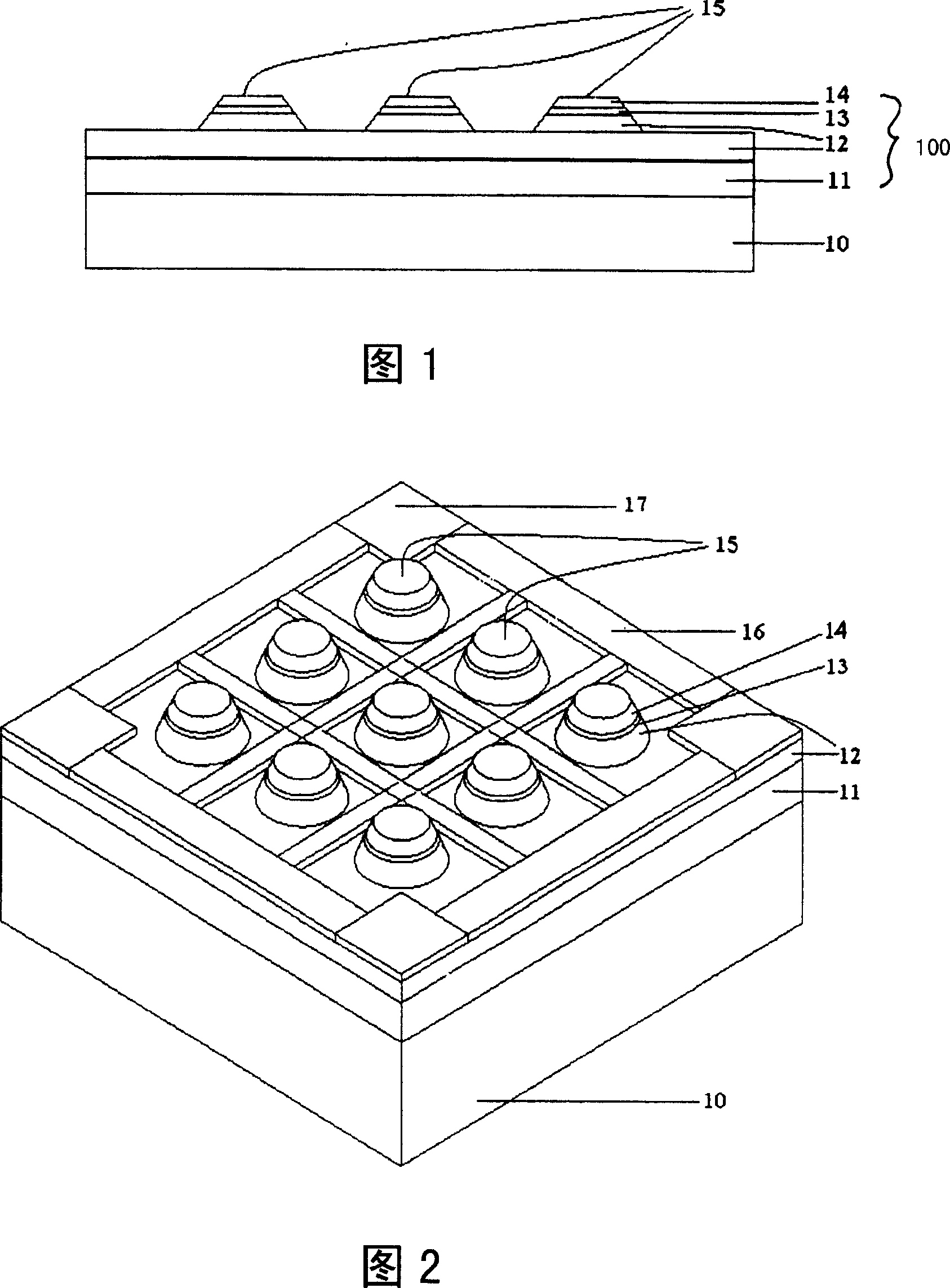

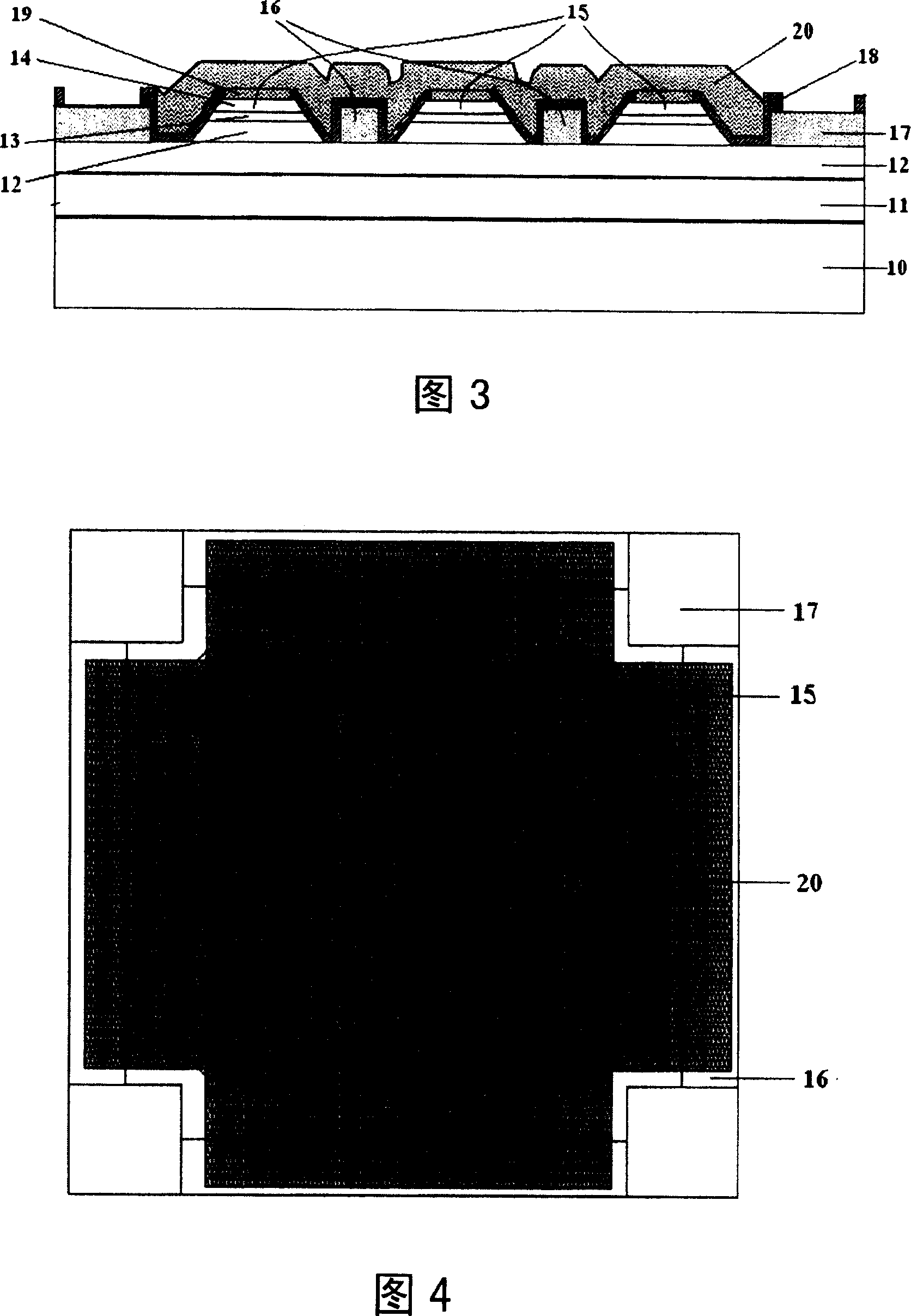

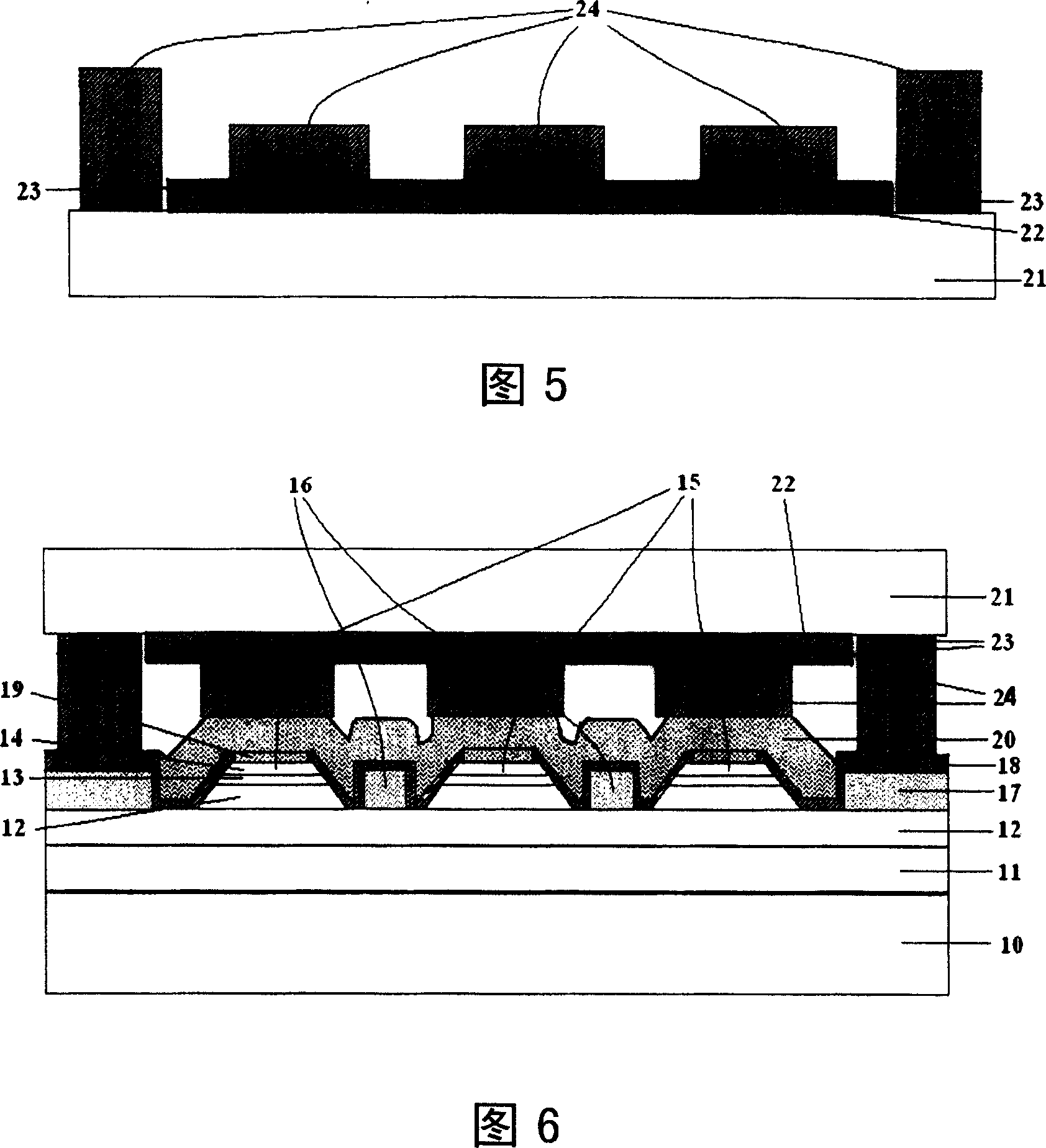

[0047]First, please refer to FIG. 1 , which is a cross-sectional view of a flip-chip microstructure GaN-based light-emitting diode die structure after the dry etching process is completed. The manufacturing process is to epitaxially grow a GaN or AlGaN buffer layer 11, an n-type GaN layer 12, an active layer 13 and a p-type GaN layer 14 on a sapphire substrate 10 by MOCVD method, and the active layer structure is InGaN / GaN or AlGaN / GaN multiple quantum wells, microstructure GaN-based power light-emitting diodes. The shape of the die is designed to be square, with a size of 1mm×1mm. The microstructure is designed to have a size of 4-20μm and a center-to-center spacing of 20-50μm. Or a square platform (the present invention takes a circular platform with a diameter of 20 μm and a center distance of 50 μm as an example). This structure increases the exit area of the light emitted by the active layer. Since the size is less than 20 μm, it greatly reduces the absorption of light ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap