Optoelectronic yarn sensor assembly

A sensor device, photoelectric technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as unreliable scanning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

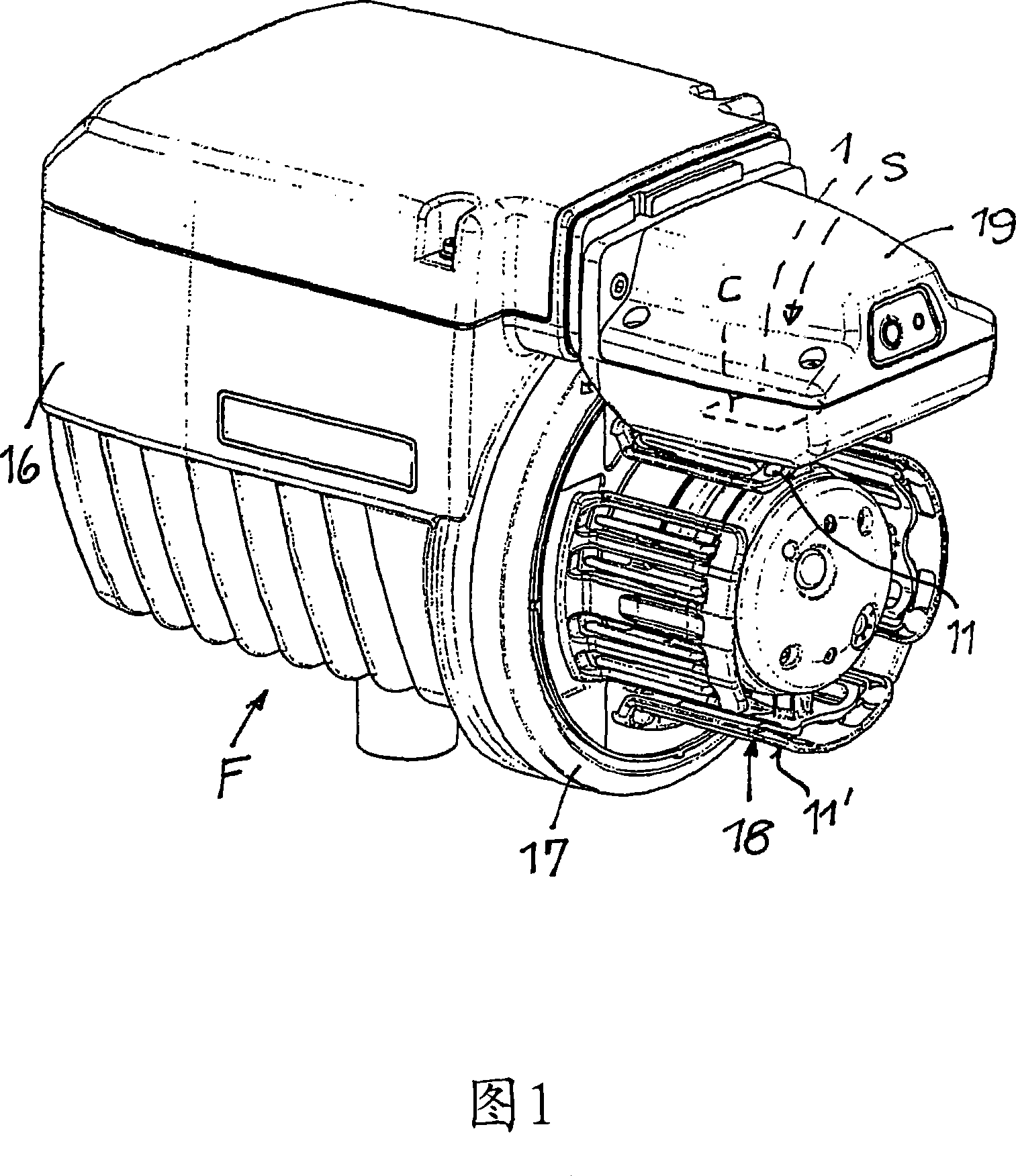

[0028] Figure 1 illustrates a weft yarn storage and measuring yarn feeding device (yarn feeder F) for a not shown jet loom. The yarn feeder F comprises a housing 16, a rotatably driven winding element 17 and a fixed storage body 18 of rod-cage type with several radial adjustment sections 11' (for diameter adjustment). The uppermost part defines a detection area 11 (for example, by a reflector arranged in this part). A casing 19 fixed to the housing 16 contains a not shown braking device for measuring the respective length of weft thread released for each weft picking. Furthermore, the housing 19 contains at least one optoelectronic yarn sensor device S, a housing part 1 covered by a transparent cover C in the vicinity of the detection area 11 .

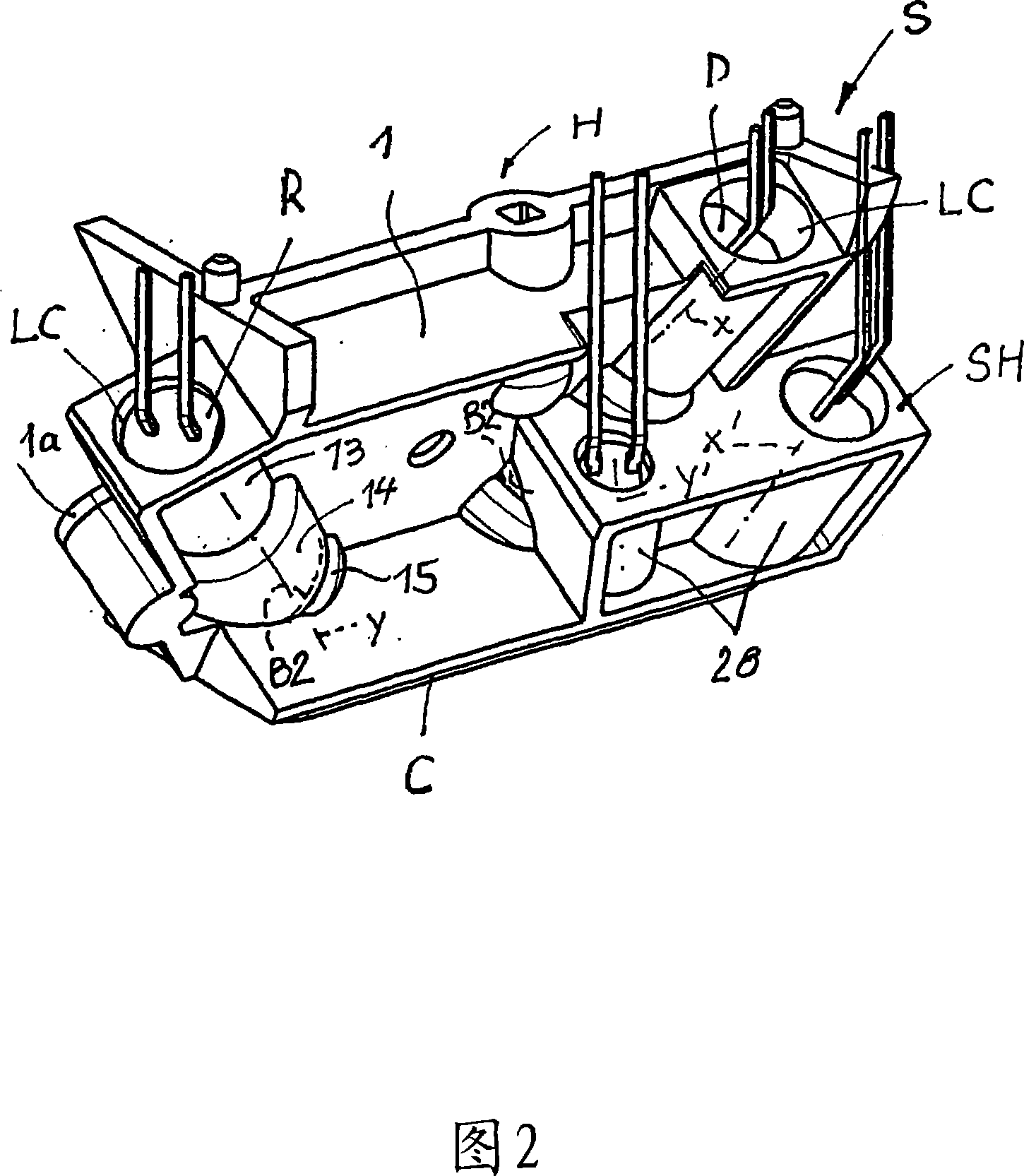

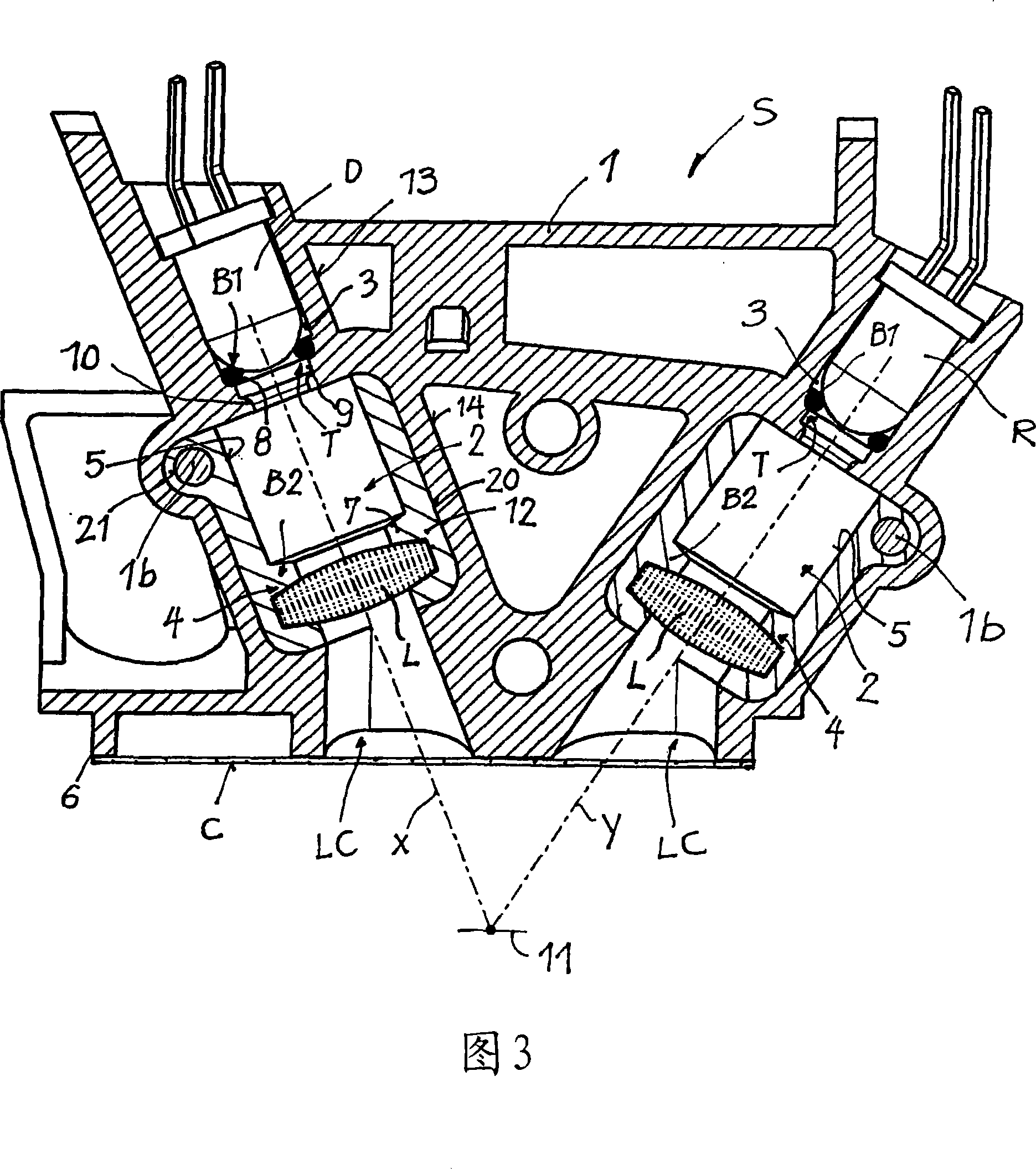

[0029] The photoelectric yarn sensor device S needs to be compact in order to use as little installation space as possible. The sensor device S is connected to an evaluation circuit (not shown) which supplies a signal for a not show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com