Method and apparatus for reducing waste mobile-oil into product mobile oil

A waste engine oil and finished product technology, applied in the direction of lubricating compositions, etc., can solve the problems of small heat dissipation, human harm, environmental pollution, etc., and achieve the effects of protecting the environment, reducing human damage, and reducing environmental pollution

Inactive Publication Date: 2007-09-05

肖青山

View PDF0 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When cleaning motor vehicles, a large amount of waste engine oil will also be produced and usually thrown away as waste, causing a lot of waste. Although waste engine oil can also be used as fuel, due to the small heat dissipation when burning waste engine oil, a large amount of concentrated oil will be produced. Smoke, which pollutes the environment a lot, is also harmful to the human body, and has little beneficial effect

When dumped as waste, it also causes great pollution to the environment, so dealing with used oil is an urgent problem to be solved at present

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

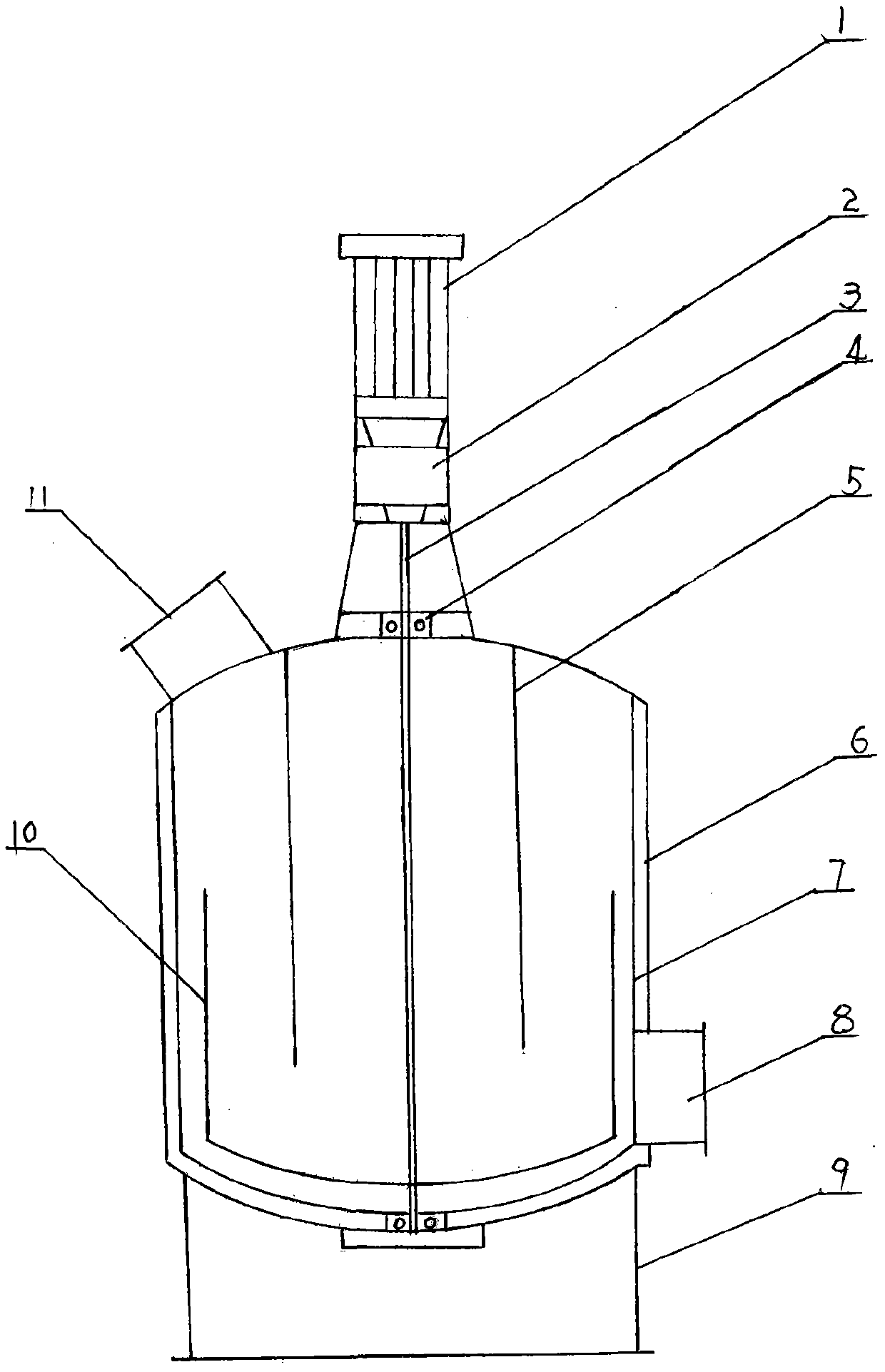

A method for reducing product mobile oil from waste mobile oil and its producer are disclosed. The process is carried out by removing water, acid washing, alkaline washing, absorbing activated clay and filtering to obtain the final product. The producer consists of motor, agitation shaft, reactor and stand. It's convenient and re-utilized, has no environmental pollution and saves resources.

Description

technical field The invention belongs to a method and equipment for reducing finished engine oil with waste engine oil. Background technique Diesel oil and gasoline are usually used to clean car dirt and oil stains on lathes and mechanical components. The dirty oil after cleaning is placed in a barrel and is called waste engine oil. Waste engine oil has no other uses and is usually thrown away as waste. When cleaning motor vehicles, a large amount of waste engine oil will also be produced and usually thrown away as waste, causing a lot of waste. Although waste engine oil can also be used as fuel, due to the small heat dissipation when burning waste engine oil, a large amount of concentrated oil will be produced. Smoke, which pollutes the environment a lot, is also harmful to the human body, and has few beneficial effects. Also cause very big pollution to environment when pouring out as waste material, thereby processing waste and old engine oil is the problem that needs to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M175/00

Inventor 肖青山

Owner 肖青山

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com