Optical control for tobacco processing industrial products

A processing industry, optical control technology, applied in tobacco, optical devices, material analysis through optical means, etc., can solve problems such as interference with optical control, error analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the following figures, identical or identical types of elements or components are identified with the same reference numerals, so that a corresponding new description is omitted.

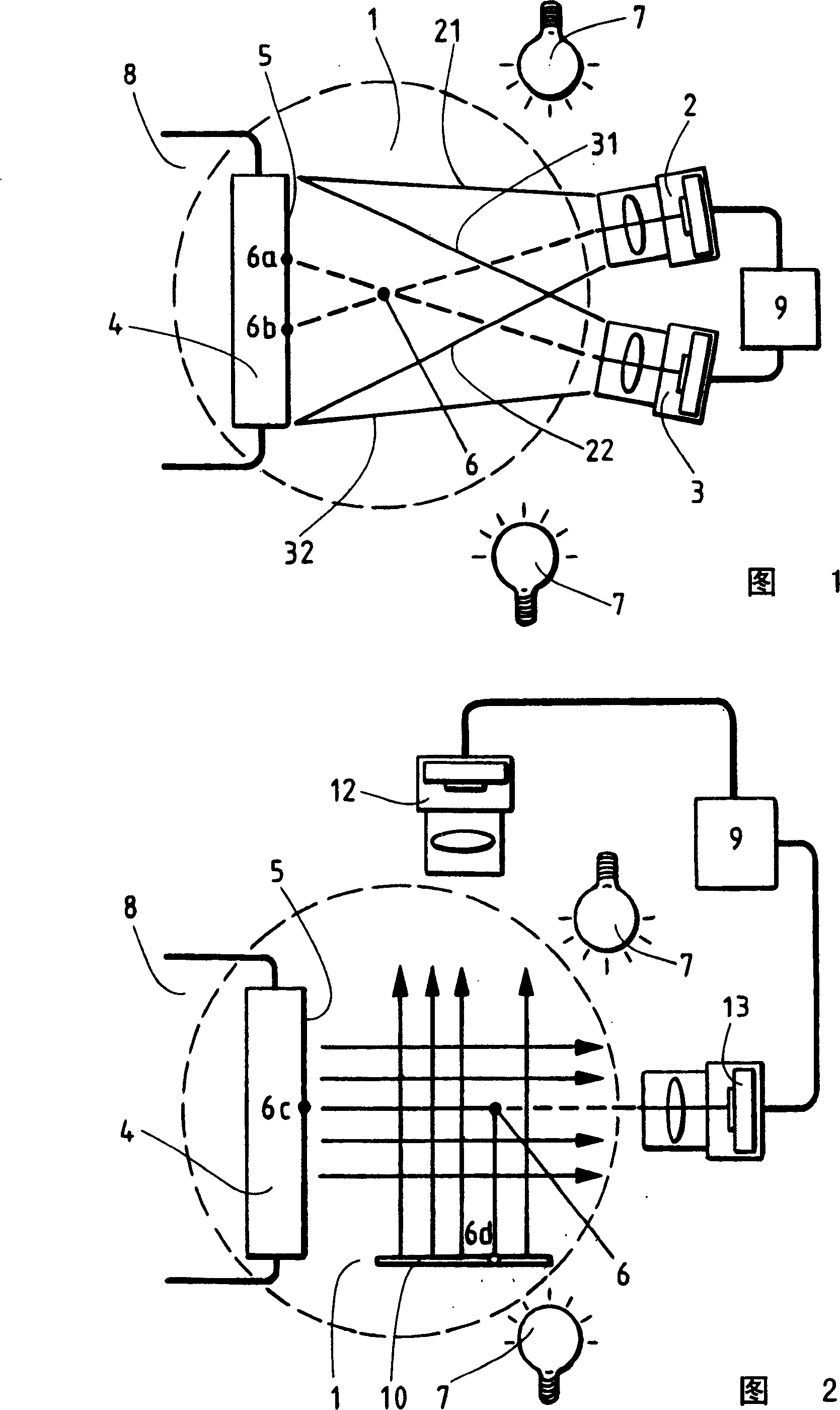

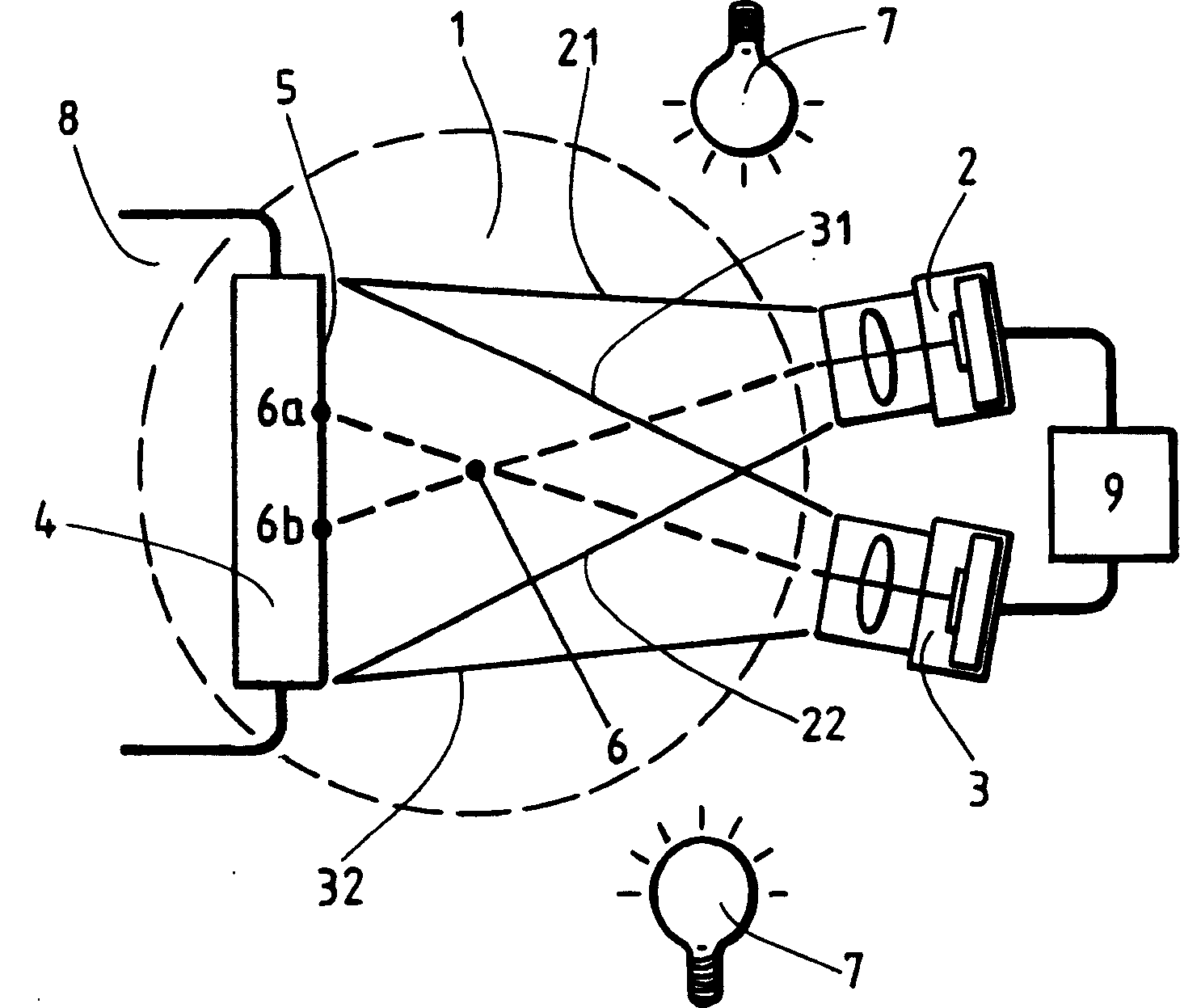

[0030] figure 1 An embodiment of the device according to the invention is briefly shown. Products 4 of the tobacco processing industry, such as cigarette rods, are located in the controlled area 1 . The products 4 are moved through this control zone in a single-layer arrangement by means of the mechanism 8 . Control zone 1 is indicated by a dotted line in the form of a closed curve. The mechanism 7 is used to illuminate the control area 1 , in particular the surface 5 of the lighting product 4 . Two camera units 2 , 3 are aimed at the surface 5 , which are connected to a unit 9 for evaluating the pictures taken by these camera units 2 , 3 . The two cameras 2 , 3 are arranged offset and at an angle to one another, ie they record the surface 5 from different directions. Furthermore, par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com