Apparatus and method for measuring rotation-axis speed by impulse

A technology of rotating shaft and rotating speed, which is applied in the field of devices that use pulses to measure the rotating speed of rotating shaft, can solve the problems of large error and frequency effect caused by interruption, and achieve the effect of reducing the error and increasing the measurement range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

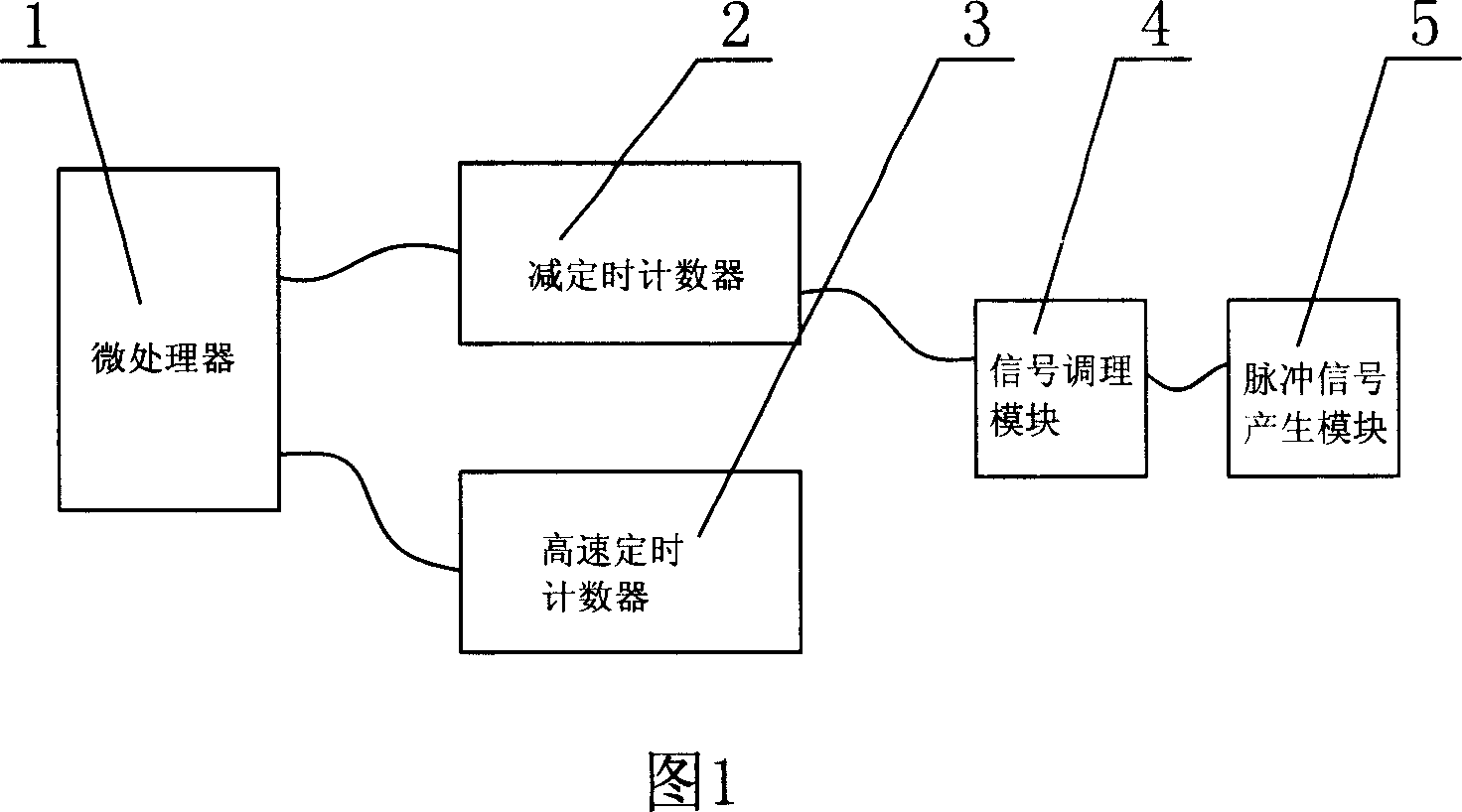

[0029] As shown in Figure 1: device of the present invention comprises microprocessor 1, high-speed timing counter 3, pulse signal generation module 5, signal conditioning module 4, pulse signal generation module 5 output terminals are connected with signal conditioning module 4 input ends, microprocessor 1 is connected with the high-speed timer counter 3, and it is characterized in that: the microprocessor 1 is also connected with a decrement timer counter 2, and the decrement timer counter 2 is also connected with the output terminal of the signal conditioning module 4.

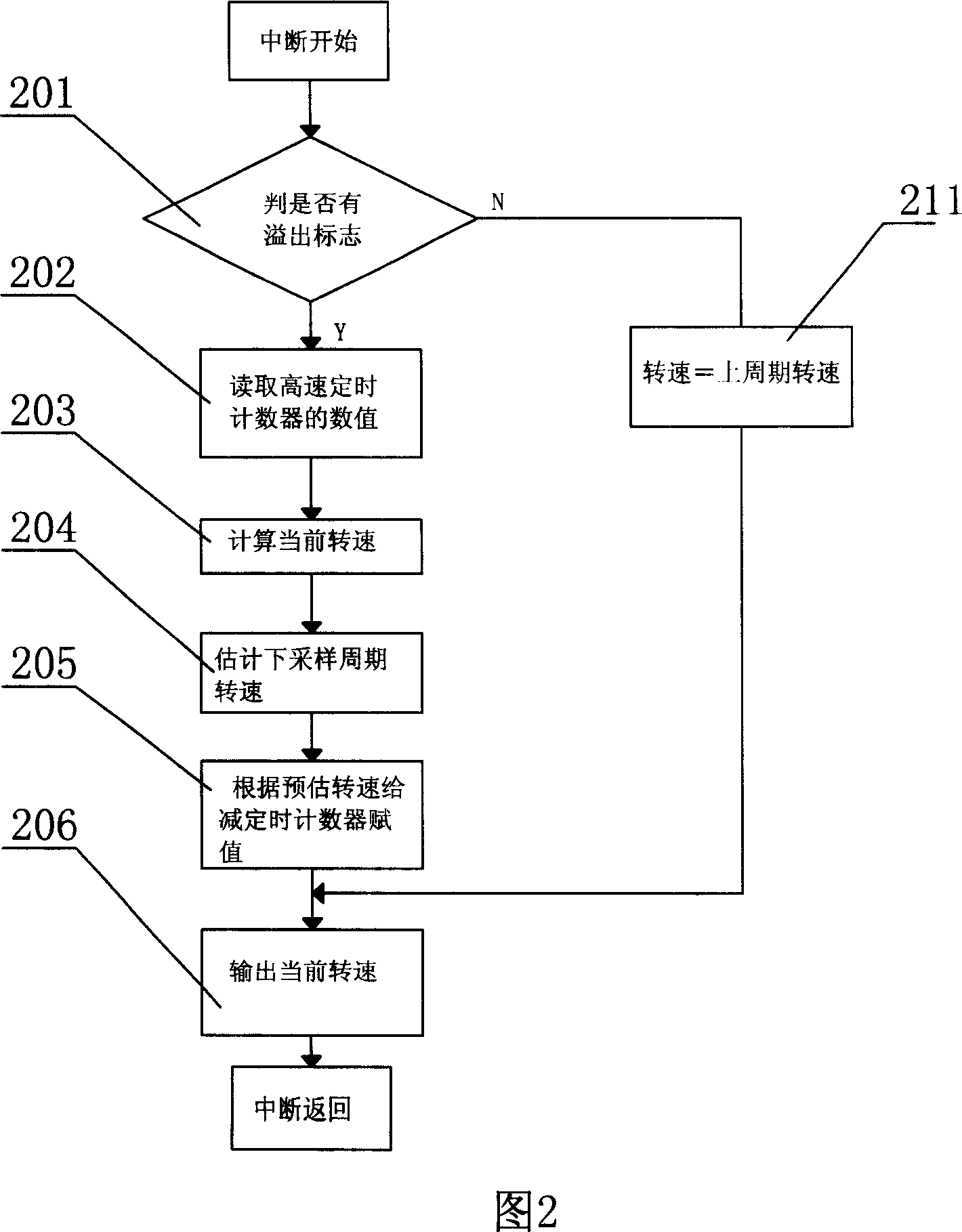

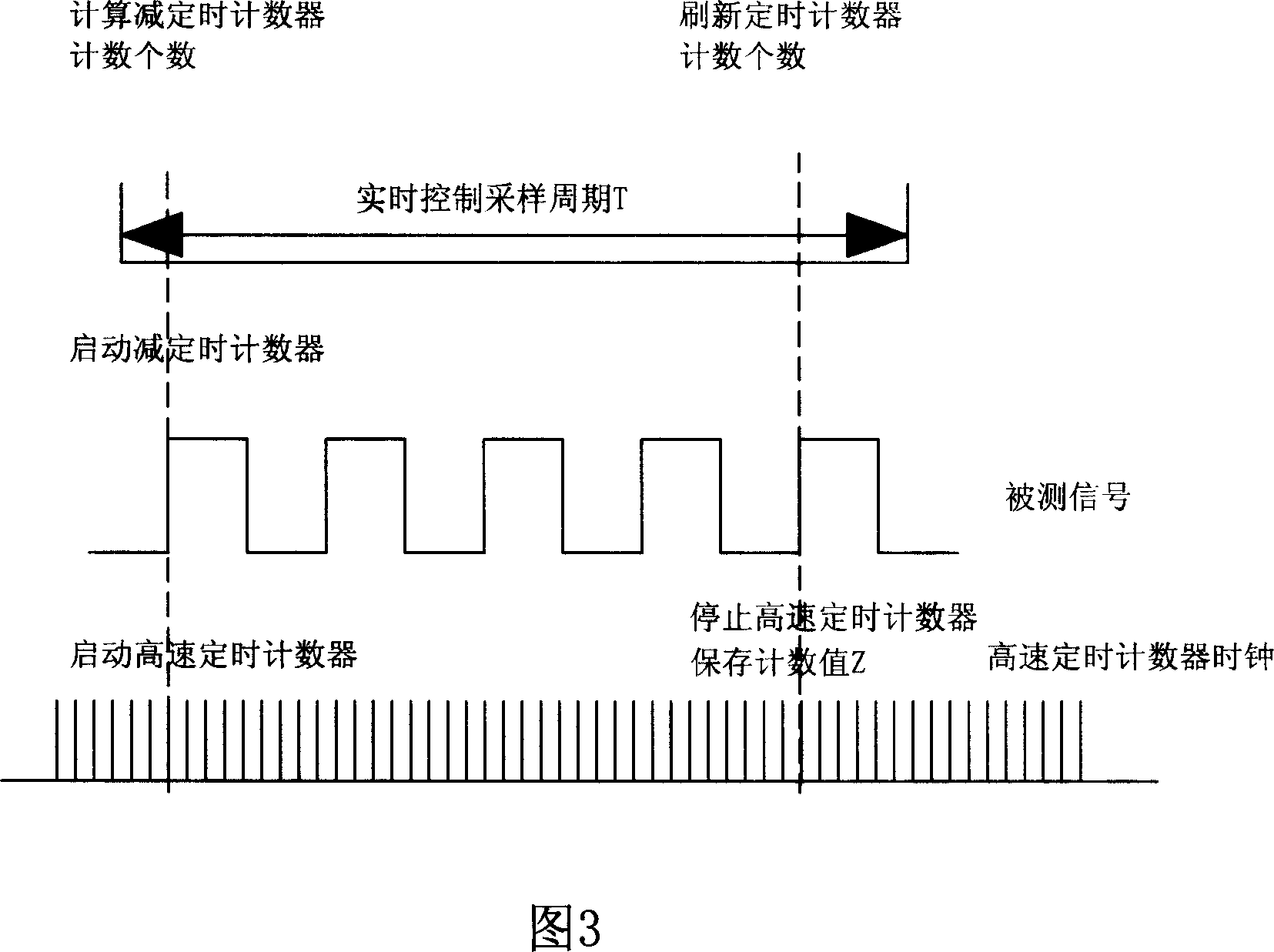

[0030] During the detection process, the gear rotation on the rotating shaft causes the pulse signal generation module 5 to generate pulses, and then the signal conditioning module 4 forms a square wave and then inputs it into the countdown timer counter 2, and the microprocessor 1 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com