Commutating diode device and its production

A technology of rectifying diodes and diodes, which is applied in semiconductor/solid-state device manufacturing, electrical components, and electric solid-state devices. The effect of using the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

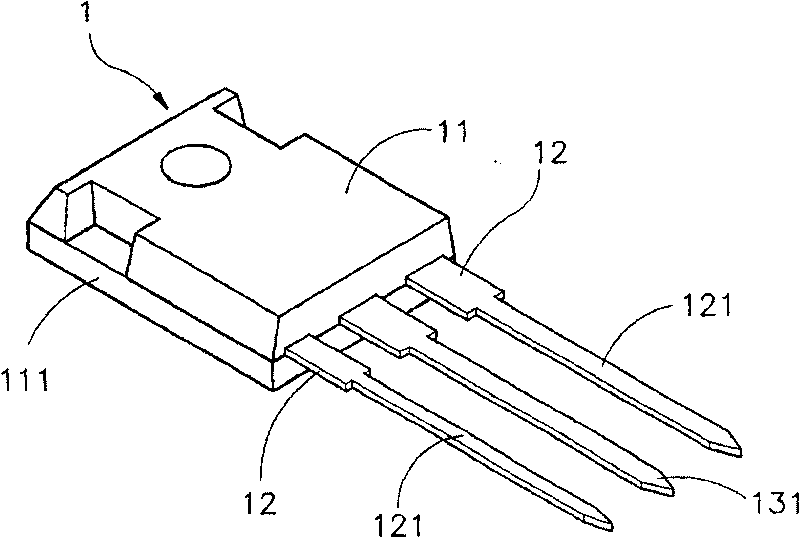

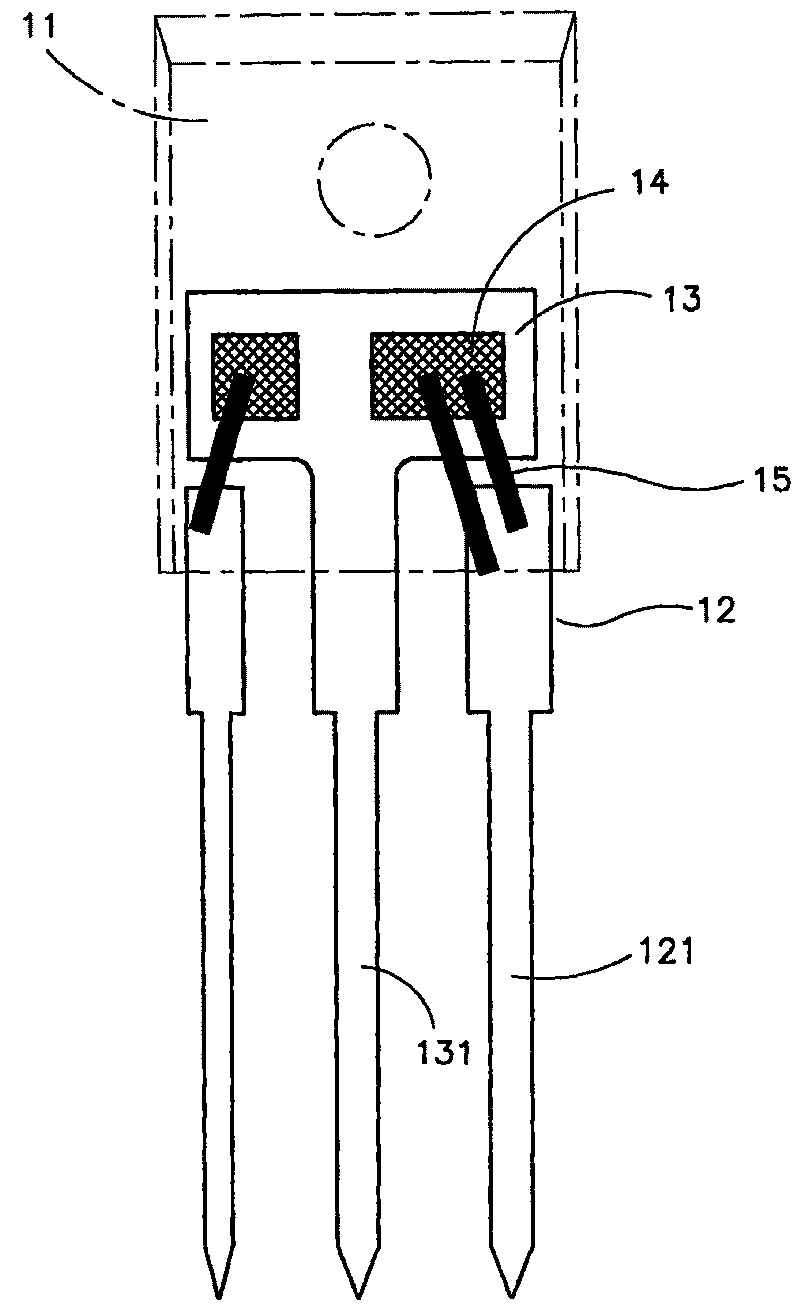

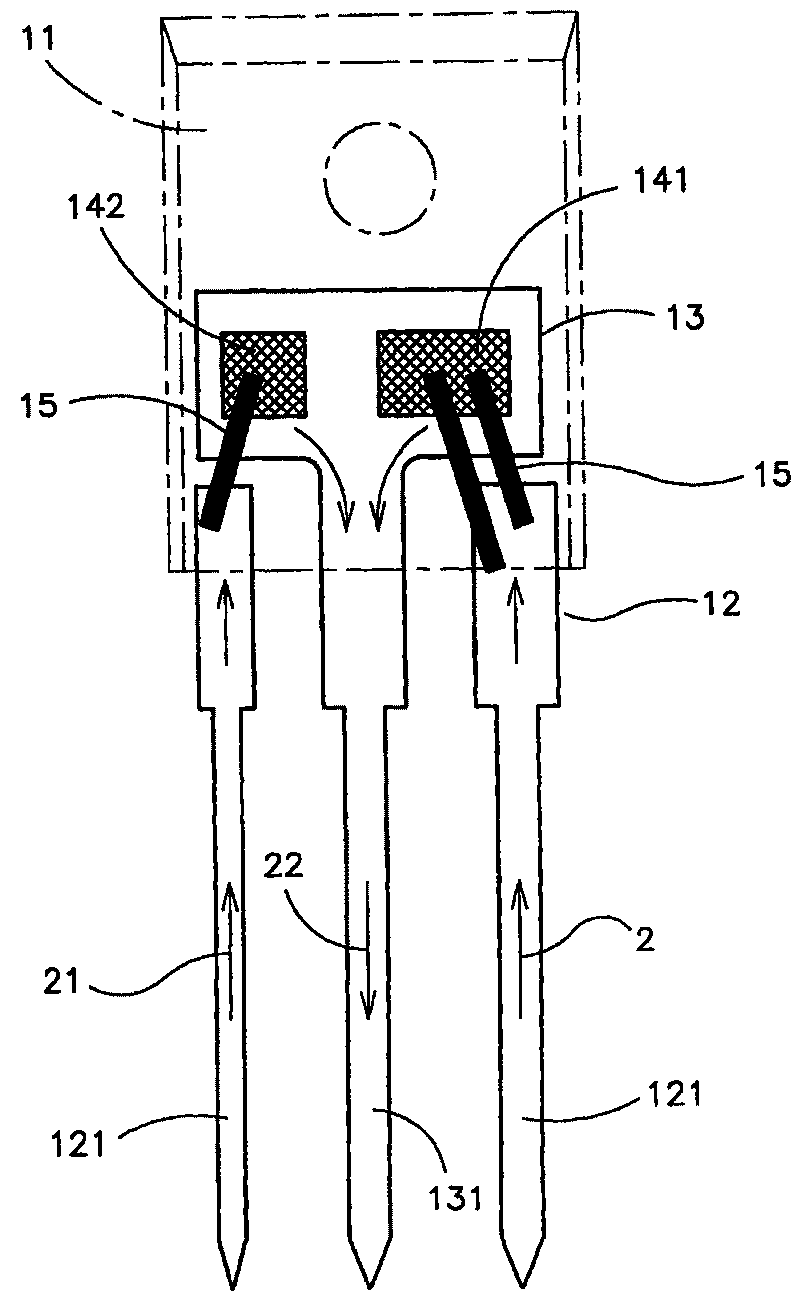

[0038] see figure 1 , figure 2 As shown, it is a three-dimensional appearance view and an internal schematic diagram of a preferred embodiment of the present invention. It can be clearly seen from the figure that the diode device 1 of the present invention has a plastic package 11, and the plastic package 11 is covered with a plurality of connecting terminals 12 and The frame 13 has an input end 121 and an output end 131 extending from each connection terminal 12 to one side of the frame 13, and the input end 121 and the output end 131 are exposed outside the plastic package 11. Furthermore, one side of the frame 13 can see through A plurality of diode crystals 14 are inherently welded by means of welding and the like, and each diode crystal 14 can be based on a difference in conduction current, a difference in conduction voltage, a difference in maximum power, a difference in allowable maximum voltage, a difference in allowable maximum current, or a allowable maximum Accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com