Temperature raising device of cigarette making roller type leaves and the control method

A drum and equipment technology, applied in the field of cigarette processing drum-like leaf warming equipment and its control, can solve the problems of unfavorable cigarette processing individual development, affecting the stability of cigarette product quality, single processing mode, etc. The effect of no fluctuation in product quality and single processing mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

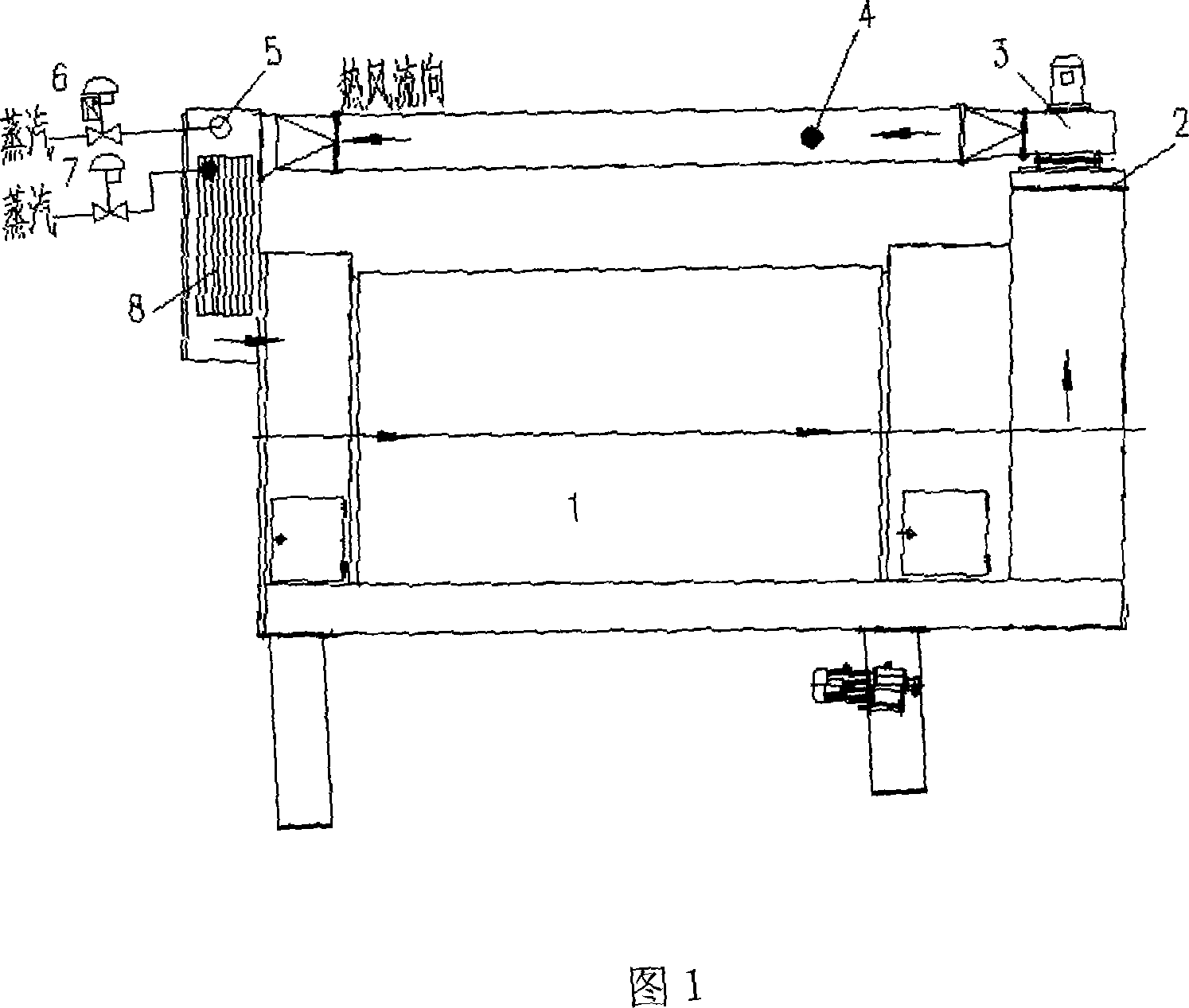

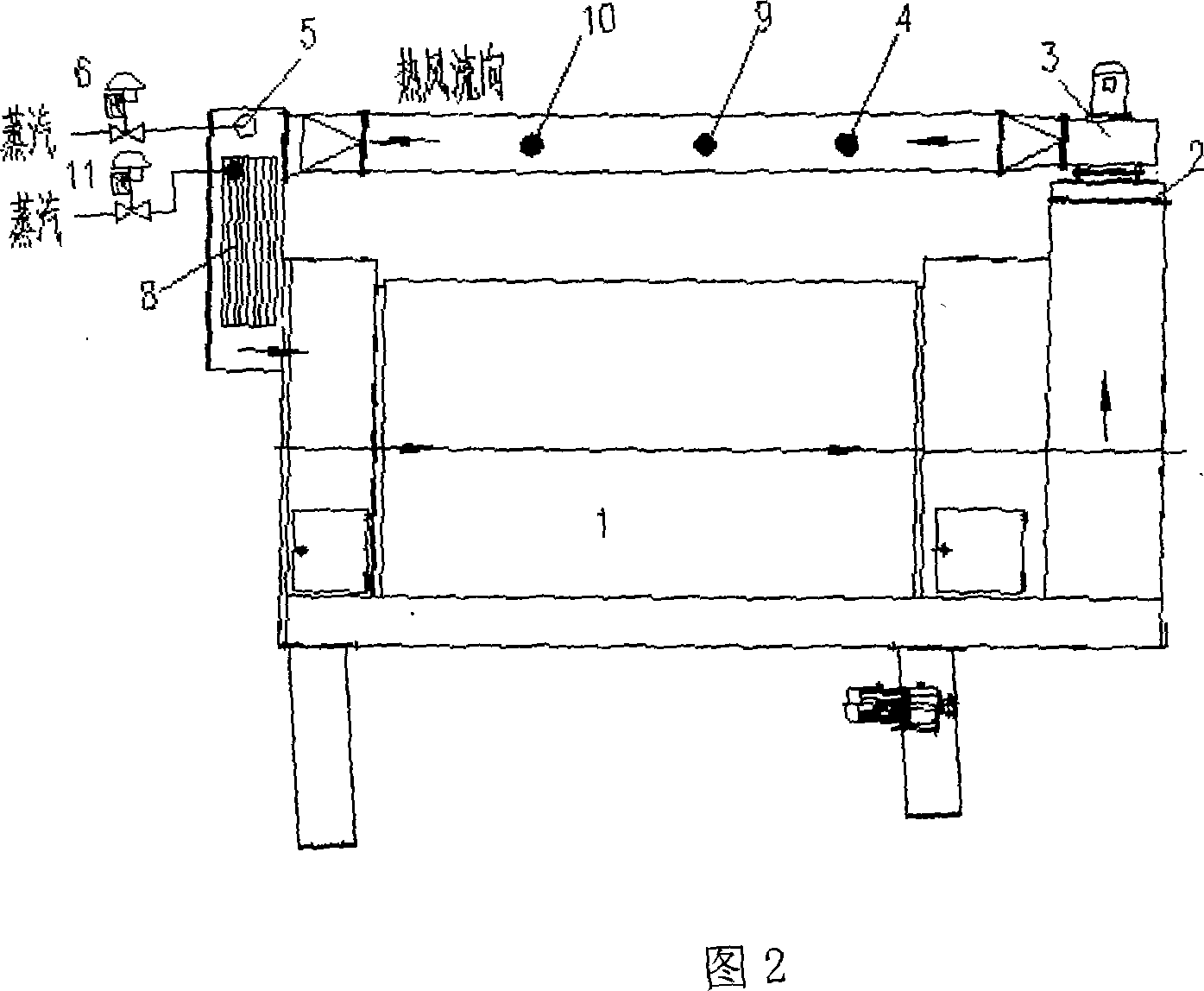

Embodiment 1

[0025] As shown in Fig. 2 and Fig. 3, a kind of cigarette processing drum type leaf warming equipment proposed according to the present invention includes: drum 1, hot air filter screen 2, hot air circulation fan 3, temperature detection device 4, steam injection pipe 5, steam injection Regulating valve 6, heat exchanger 8, it also includes: frequency converter, programmable logic controller PLC; There is a temperature detection device 4 on the circulation air pipe connecting heat exchanger 8 and hot air circulation fan 3. Humidity detection device 9 and an air volume detection device 10, the combination of described humidity detection device 9, air volume detection device 10 and temperature detection device 4 can simultaneously detect the temperature, humidity and air volume of process air flow; at the steam inlet of heat exchanger 8 A heat exchanger regulating valve 11 is provided at the place, and the heat exchanger regulating valve 11 can control and regulate the heat excha...

Embodiment 2

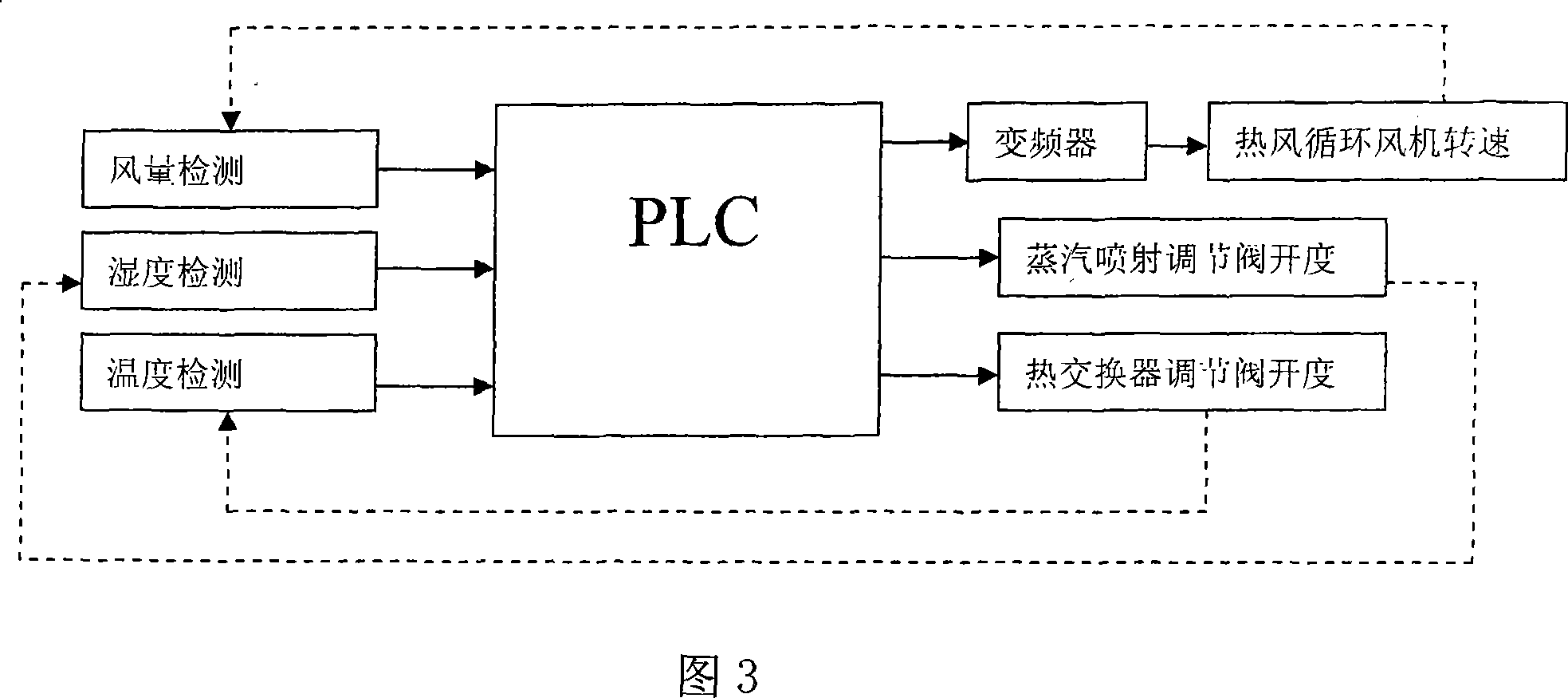

[0027] As shown in Fig. 3, the present invention is used to realize the control method of cigarette processing cylinder type leaf warming equipment and comprises, and this method comprises the following circulation process steps and circulates:

[0028] A. On-line detection, the temperature, humidity and air volume data of the process air flow detected immediately by the humidity detection device 9, the air volume detection device 10 and the temperature detection device 4 are transmitted to the programmable logic controller PLC in the direction of the solid line arrow;

[0029] B. Automatic control, the programmable logic controller PLC compares the difference between the detected data according to the set process parameters, and enters the following one or two or all of the following processes in the direction of the solid arrow:

[0030] (a) Flow adjustment, the frequency is changed by the frequency converter, and the wind speed of the hot air circulation fan 3 is changed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com