Method and device of automatic spray paint

A technology for automobiles and baking rooms, which is applied to devices and coatings that apply liquid to the surface. It can solve the problem that the delivery date of estimated vehicles cannot be confirmed with customers, the foundation of mutual trust between vehicle owners and repair shops is insufficient, and the cleanliness of traditional paint baking ovens is affected. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

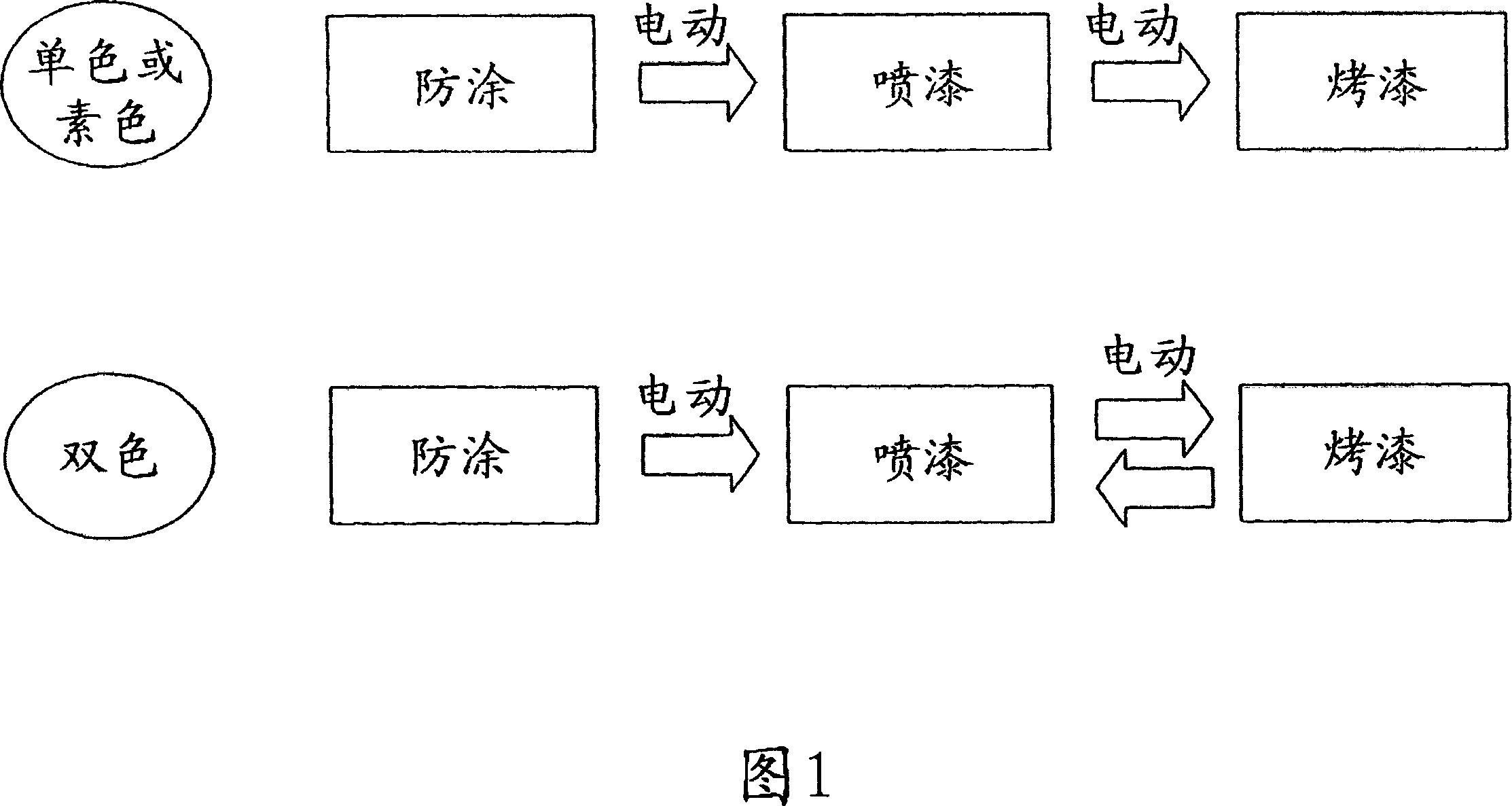

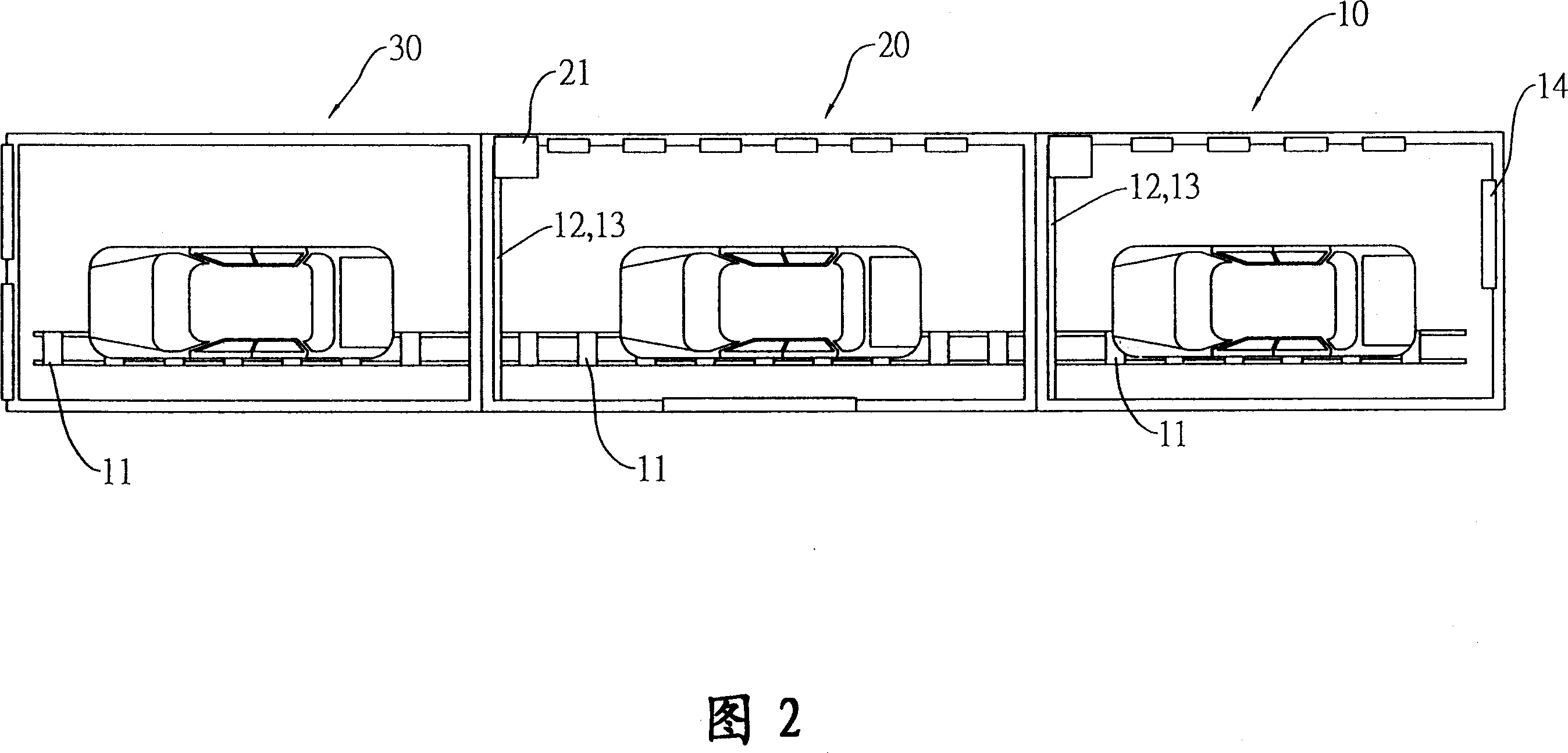

[0024] The present invention is a kind of automobile spray baking method and device (as shown in Fig. 1, 2), hereby further with preferred embodiment as shown in Fig. 1, detailed description is as follows, the present invention includes:

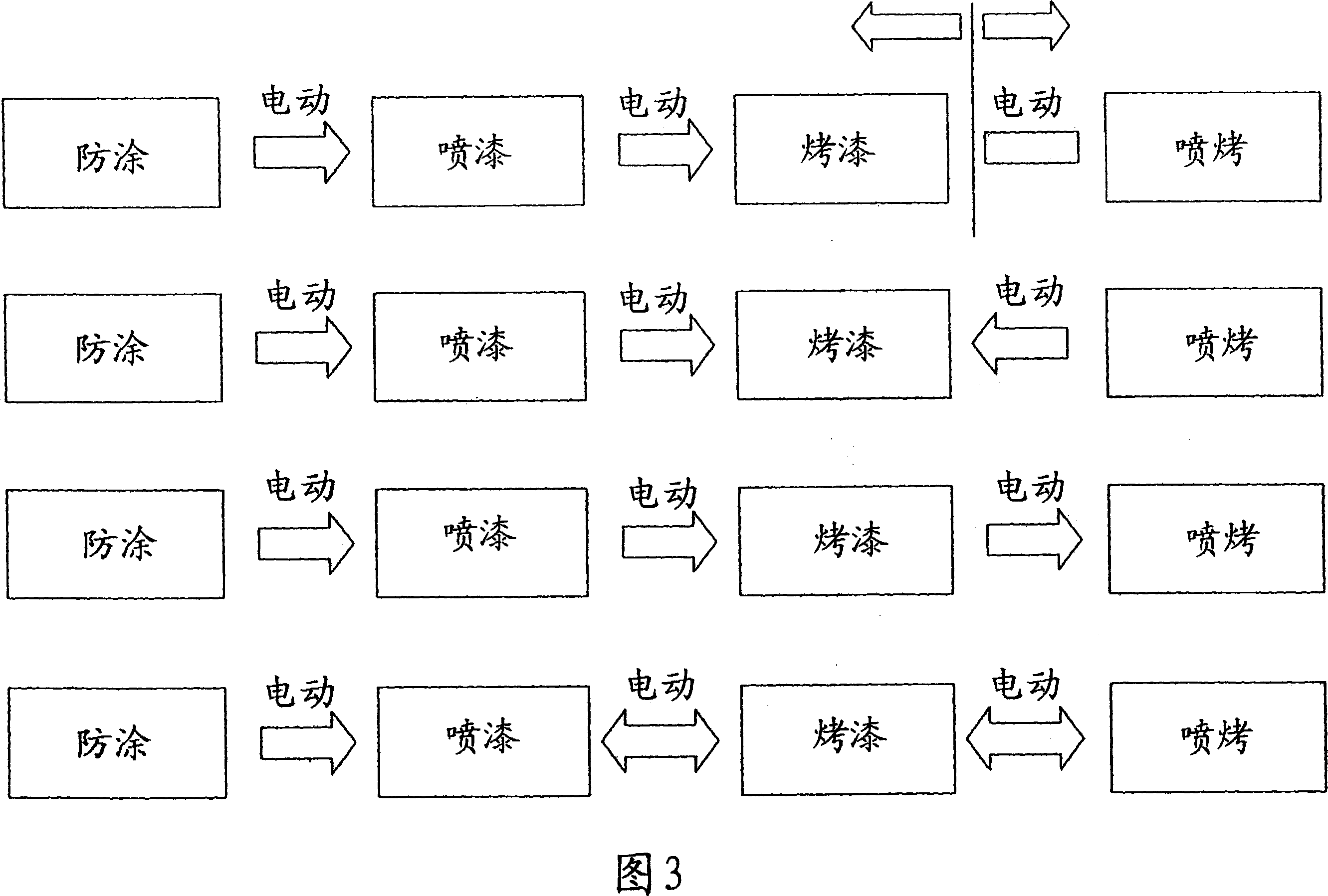

[0025] The present invention mainly improves the paint spraying and baking process of the original vehicle paint repairing operation, breaks the traditional method of completing spraying and baking in only one paint oven, and creates a production line type three-compartment spray oven. The construction process is divided into three compartments of anti-coating, spray painting, and baking paint. It can be a fast procedure from anti-coating to baking paint to improve quality and efficiency.

[0026] In order to ensure that the production capacity of the three-compartment integrated spray oven can be smoothed and utilized to the maximum extent, the scheduling system in the factory is used to arrange the time for each station to enter the site ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com