Heat mould feeding method of compound region polymer embryonic plant

A technology of polymer and embryonic body, which is applied in the field of hot-molding of compound polymer embryos, can solve the problems of inability to obtain polymer embryos, inability to carry out implementation, loss and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

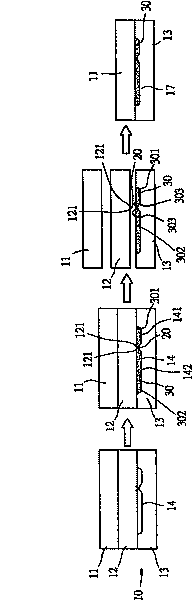

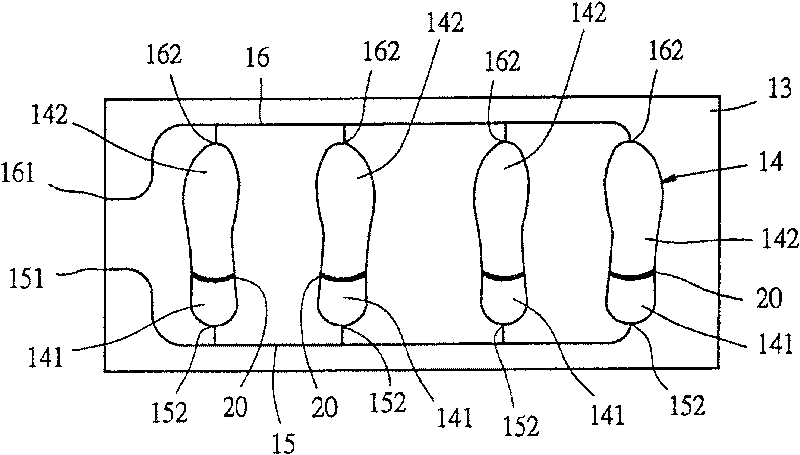

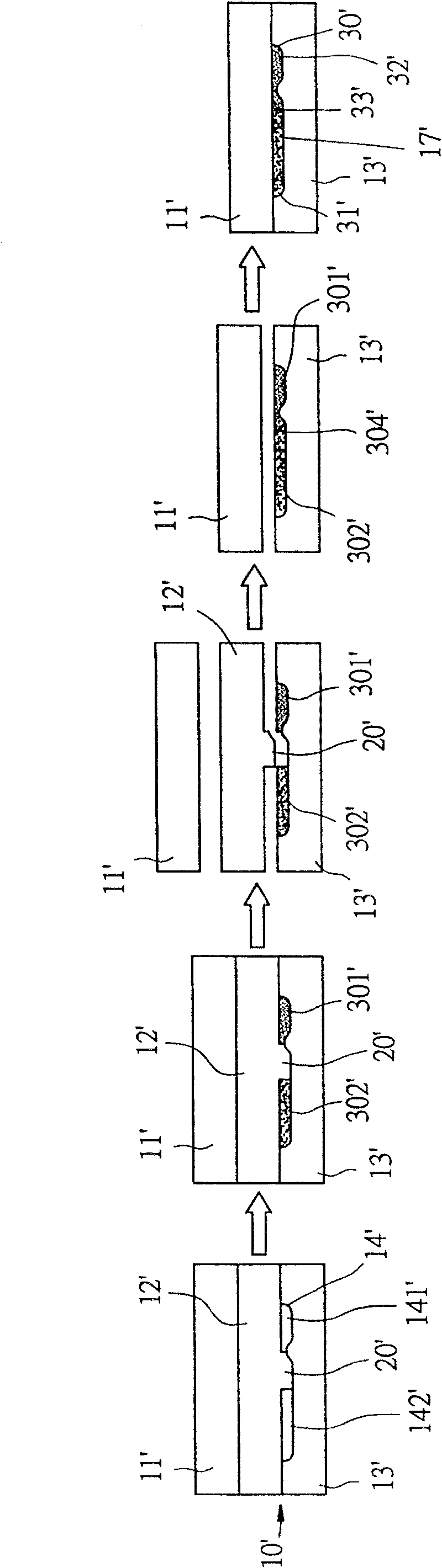

[0016] First, see figure 1 and figure 2 As shown, in the first preferred embodiment of the present invention, the thermal mold injection method of the multi-zone polymer green body is provided, which includes the following steps:

[0017] a. Take a mold 10 maintained in a predetermined temperature range, the mold 10 is formed by overlapping the first, second and third templates 11, 12, 13 with each other, and the second and third templates 12, 13 An inner blank mold chamber 14 is formed between them, and a first runner and a second runner 15, 16 are respectively arranged in the mold 10 to communicate with the different positions of the blank mold chamber 14 and the outside of the mold 10, and Forming corresponding first and second material injection ports 151 and 161 on the surface of the mold 10 respectively, and forming corresponding first and second material inlets 152 and 162 on the wall of the blank mold chamber 14;

[0018] The blank body mold chamber 14 is partitione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com