High performance louver

A louver, high-performance technology, applied to windows/doors, door/window protection devices, shading screens, etc., can solve problems such as system jamming and easy misalignment of sheets, and achieve high reliability, simple transmission, and practicality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

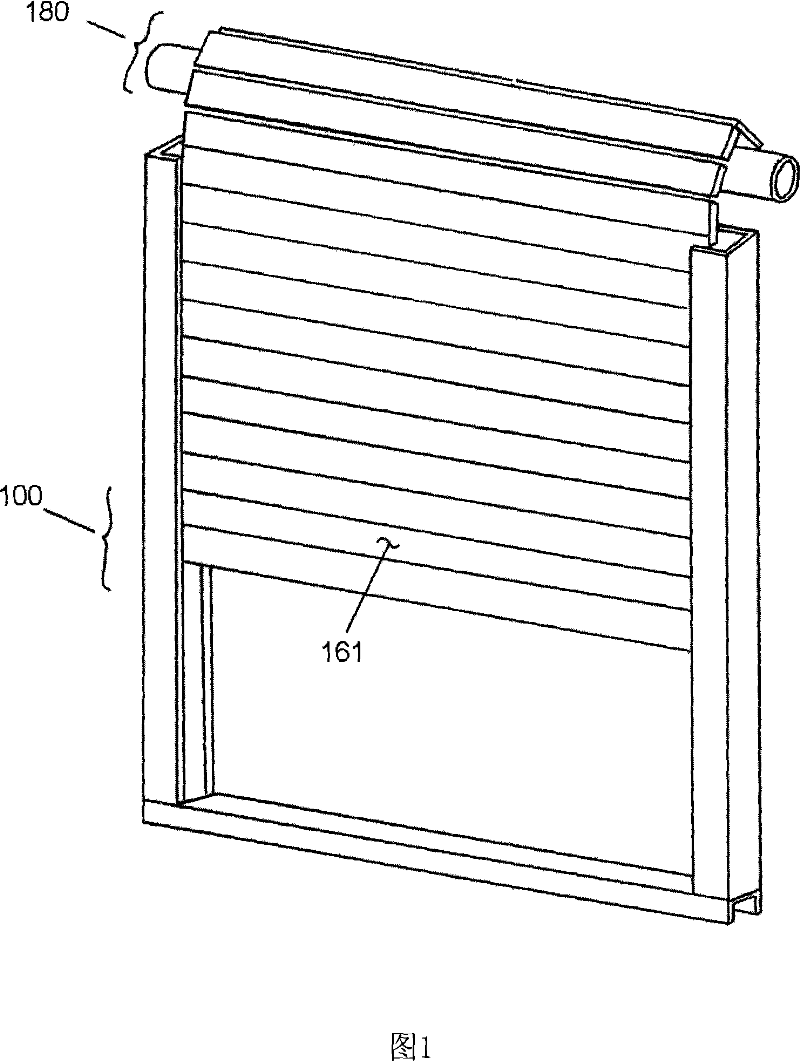

[0040] According to FIG. 1 , the shutter in this embodiment includes a frame body 100 and a storage mechanism 180 , and the frame body 100 is installed on a relatively fixed covering body, such as the outer surface of a door or window. A group of sequentially arranged and synchronously flipped pages 161 is placed in the frame body 100, and the storage mechanism 180 provides the power for the pages 161 to move up and down. The power required for the traditional rolling door to go up and down is provided by the motor and transmission device located in the storage mechanism 180 .

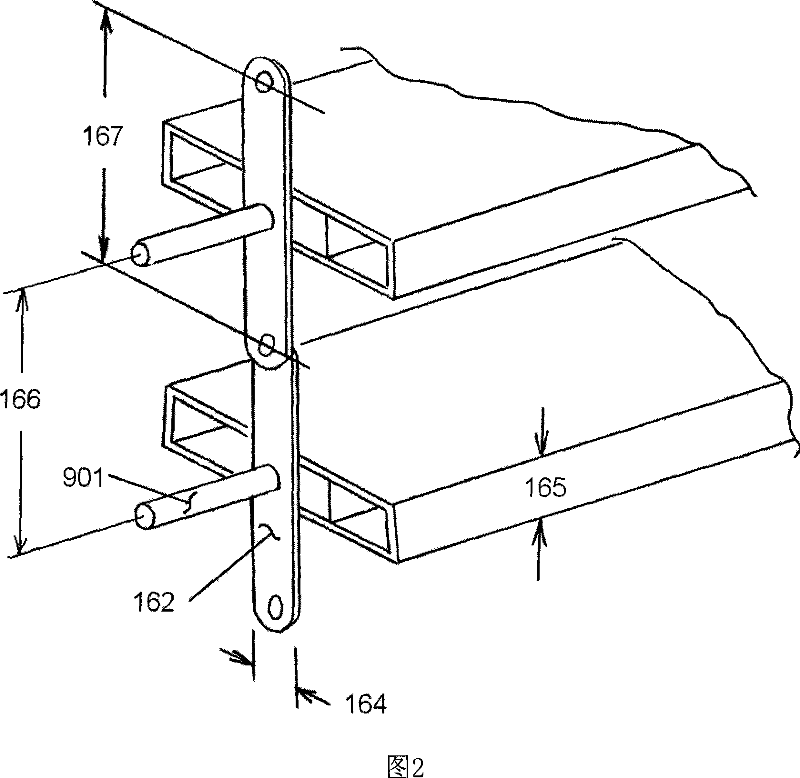

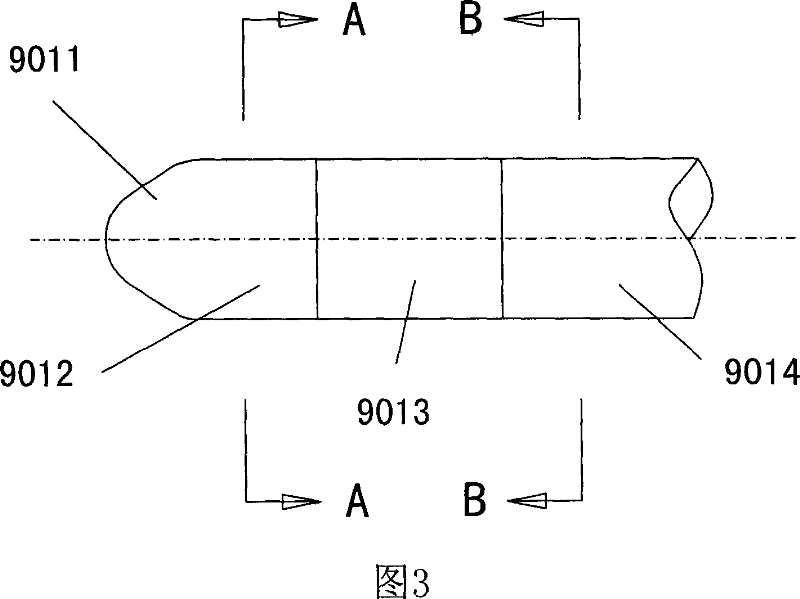

[0041] In this embodiment, as shown in Figure 2, chain components 162 are used to connect the sheets 161 to each other. The chain components 162 are useful high-strength sheets. In order to avoid mutual interference after winding, its width 164 and thickness 165 of the sheets must be equivalent, in order to maintain excellent operational performance, the center distance 167 of the chain connection hole...

Embodiment 2

[0055] As shown in FIG. 12 , the shutter in this embodiment includes a frame body 200 and a storage mechanism 280 , and the frame body 200 is installed on a relatively fixed covering body, such as the outer surface of a door or window. A group of sequentially arranged and synchronously flipped pages 261 is arranged in the frame body 200, and the storage mechanism 280 provides the power for the pages 261 to move up and down. For traditional sunshade shutters, the power required for its up and down is provided by the motor and transmission device located in the storage mechanism 280 . The main difference between this embodiment and Embodiment 1 is that: as shown in Figure 13, in this embodiment, the plates 261 are connected by fixed-length stainless steel flexible suspension cables, and the ends of each leaf 261 are attached The terminal 267 passes through the middle suspension cable 265 in the middle of the terminal 267, and the front and rear ends of the terminal 267 are respe...

Embodiment 3

[0058] As shown in Figure 14, the main difference between this embodiment and Embodiment 1 or Embodiment 2 is: in this embodiment, the storage mechanism 380 is located at the bottom of the frame 300, and the leaf 361 must rise to the top of the frame 300 when operating to cover the entire protected window. As for other principles, structures, and methods that are the same or similar to those described in Embodiment 1 or Embodiment 2, details will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com