Integration shielding plug

A shielding plug, an integrated technology, applied in the direction of connecting parts, protective grounding/shielding devices, electrical components, coupling devices, etc., can solve the problems of complex processing technology, poor shielding effect, and many defective products, and achieve simple processing technology, Easy to use, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

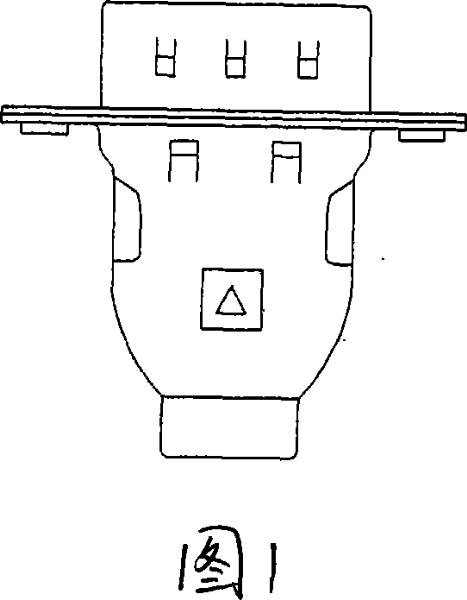

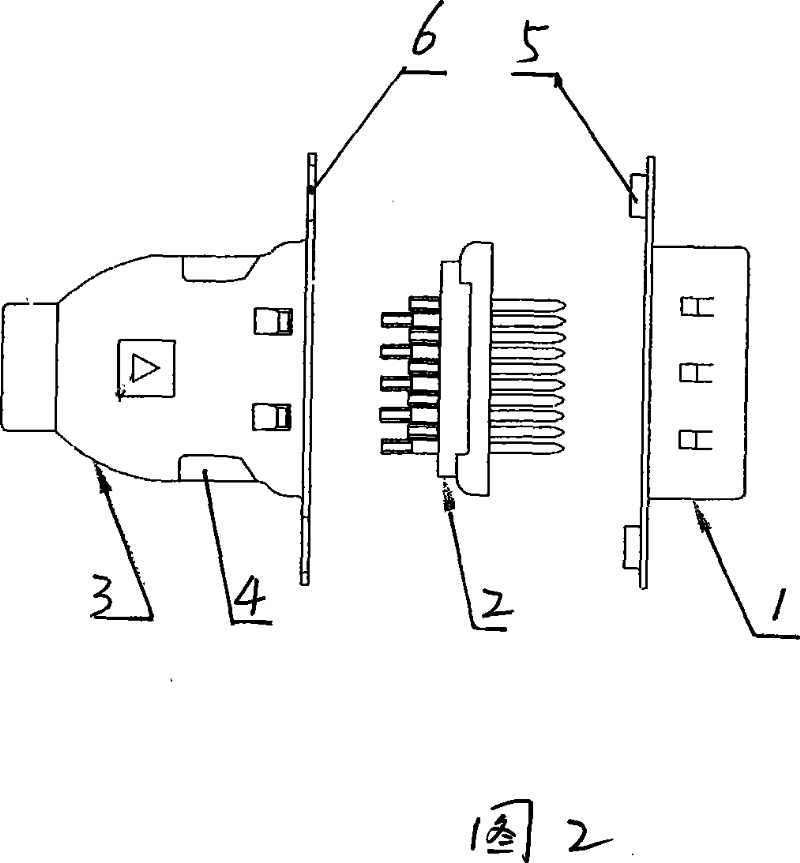

[0010] In the figure: 1. front shell, 2. functional parts, 3. rear shell, 4. groove, 5. post, 6. bayonet.

[0011] It can be seen from FIG. 1 and FIG. 2 that an integrated shielded plug is composed of a front shell 1 , a functional part 2 and a rear shell 3 . Wherein, the front port of the front shell 1 is the interface of the integrated shielding plug of the present invention, which is rectangular and trapezoidal, and can be directly plugged into the computer during use. One end of the functional component 2 is plugged into the rear port of the front case 1 , and the other end is plugged into the upper port of the rear case 3 with a signal line. The rear shell 3 is a one-piece structure formed by one-time evacuation and stretching. Its appearance is like a rectangular funnel. The upper port is connected to the functional parts, and the lower funnel port is a circular port for wrapping signal cables. The shell of the back shell 3 is provided with grooves 4 of various shapes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com