High-voltage capacitor

A technology of high-voltage capacitors and capacitors, applied in the direction of capacitors, fixed capacitors, multiple fixed capacitors, etc., can solve problems such as restrictions, and achieve the effects of avoiding voltage differences, compact placement, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

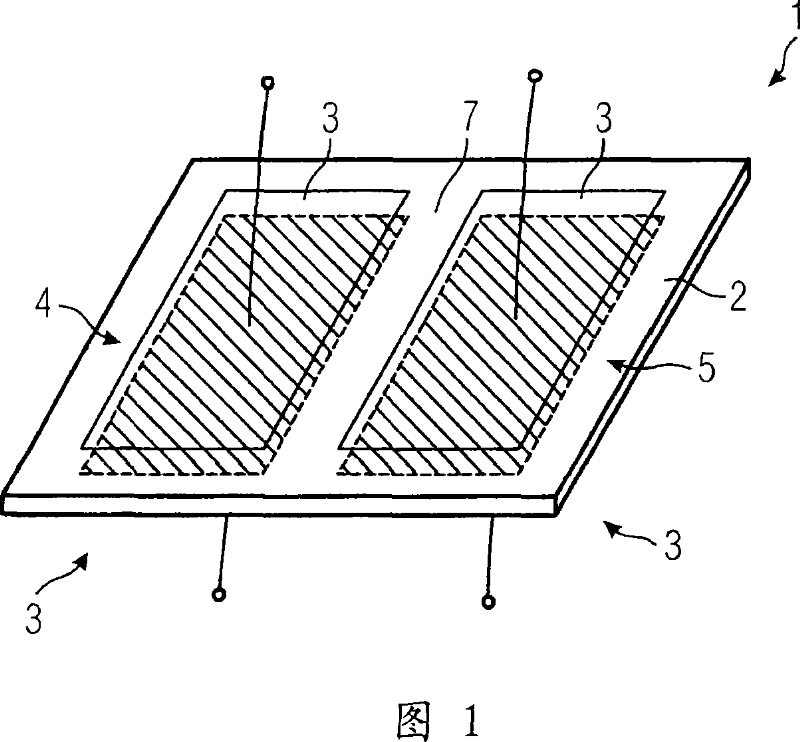

[0019] Fig. 1 shows an embodiment of a capacitor element 1 according to the invention before it is wound. The illustrated capacitor element 1 consists of an insulating or dielectric film 2, on both sides of which a thin metal foil 3 is applied as an electrically conductive coating. A total of four metal foils 3 can be seen here, two of which are located opposite each other in pairs on different sides of the insulating film 2 and thus form a first individual capacitor 4 and a second individual capacitor 5 . The individual capacitors 4 and 5 are insulated from each other by an insulating spacer 7 extending between the individual capacitors 4 and 5 . By mounting the two individual capacitors on the insulating or dielectric film 2, the individual capacitors 4 and 5 can be designed substantially symmetrically to each other.

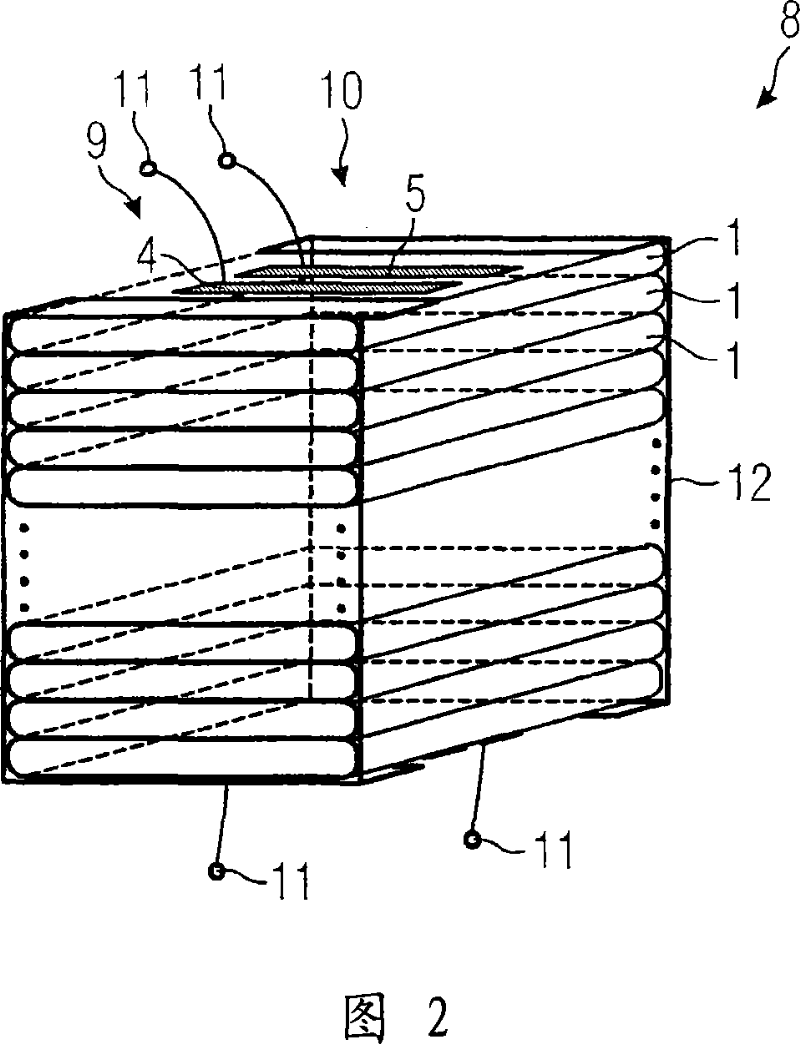

[0020] FIG. 2 shows an exemplary embodiment of an active component 8 consisting of capacitor elements 1 arranged one above the other. The capacitor elements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com