A Conjugate Iron Core for 24-pulse Rectifier Transformer

A technology of pulse wave rectification and transformers, which is applied in the field of transformers, can solve the problems of high manufacturing cost of rectifier transformers, high transformer losses, and large unit footprint, and achieve low manufacturing costs, low transformer losses, and small footprints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in conjunction with accompanying drawing and specific embodiment:

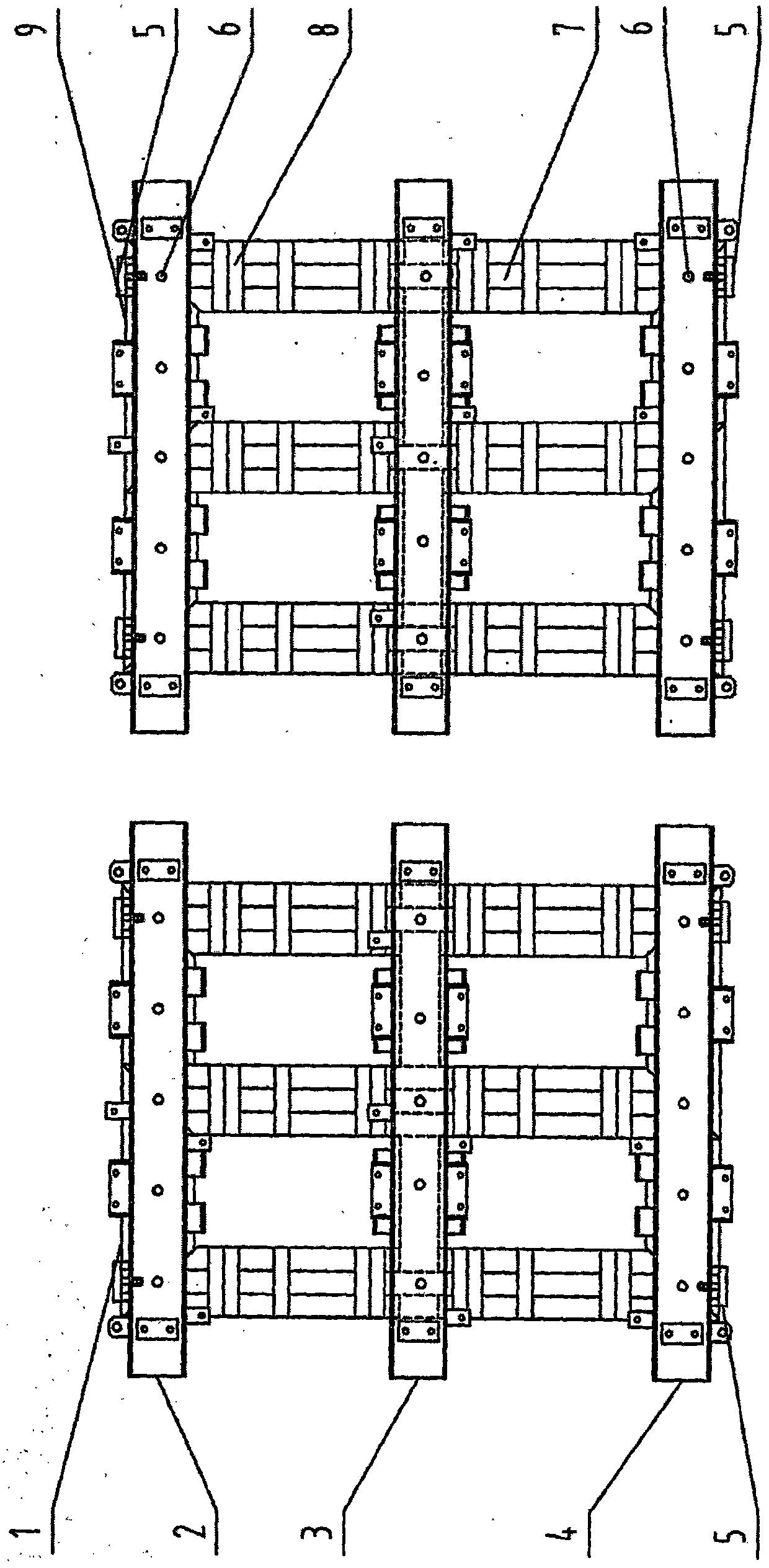

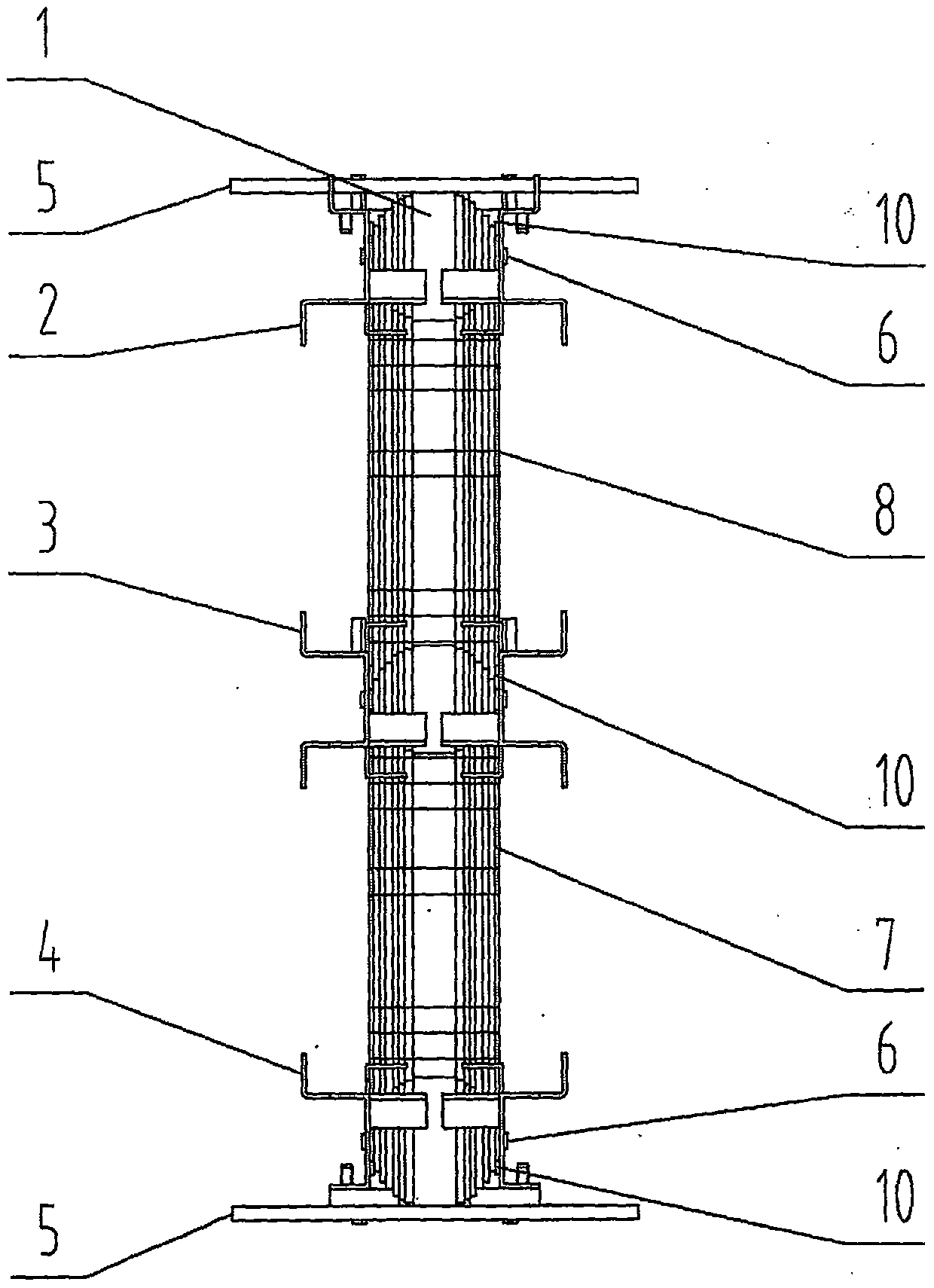

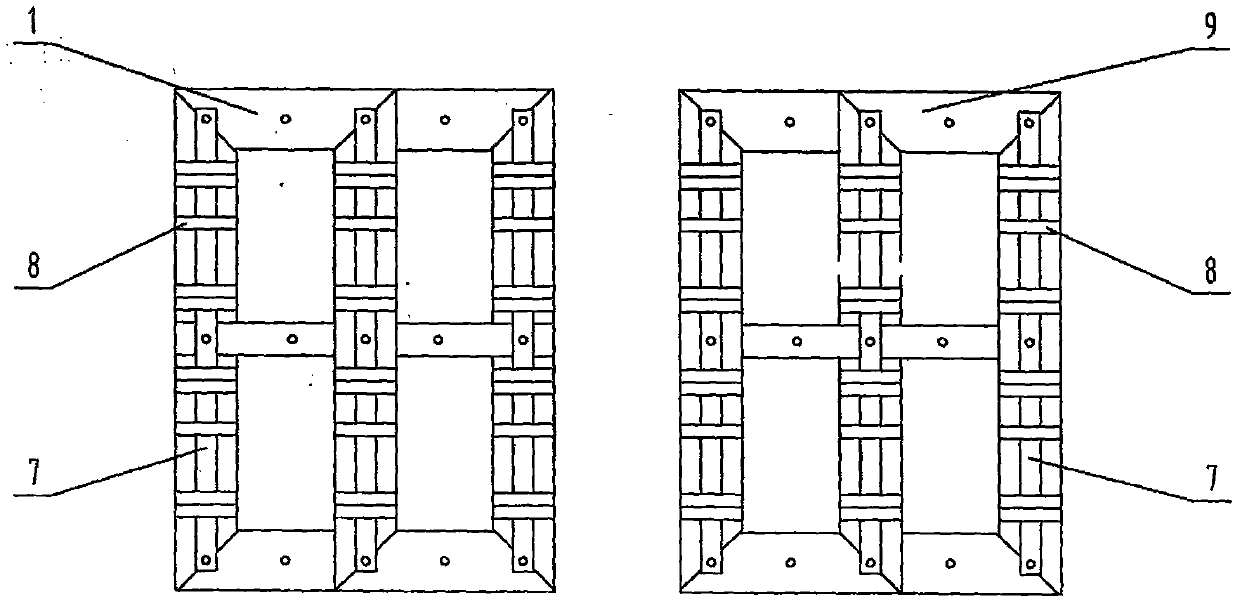

[0023] Such as figure 1 and figure 2 As shown, the 24-pulse rectifier transformer of the present invention uses a conjugate core, which includes a first core assembly 1 and a second core assembly 9 vertically arranged in a left-right symmetrical manner, and the first core assembly and the second core assembly The components all include a square-shaped iron core, and the upper clamping parts 2 and middle clamping parts 3 are respectively arranged on the front and rear sides of the iron core at equal intervals from top to bottom, and are used to clamp the upper, middle and lower horizontal core parts of the iron core. And the lower clip 4, and the anchors 5 arranged at the upper and lower ends of the iron core; stainless steel pull plates 7 are arranged on the front and rear sides of the vertical iron core column of the iron core, and the upper, middle and lower clips ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com