Washing device of closed barrel

A technology of supporting buckets and brushing buckets is applied in the field of closed bucket brushing devices, which can solve the problems of low working efficiency, affecting brushing quality, and small washing force, etc., and achieve the effects of high working efficiency, good cleaning quality and short brushing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

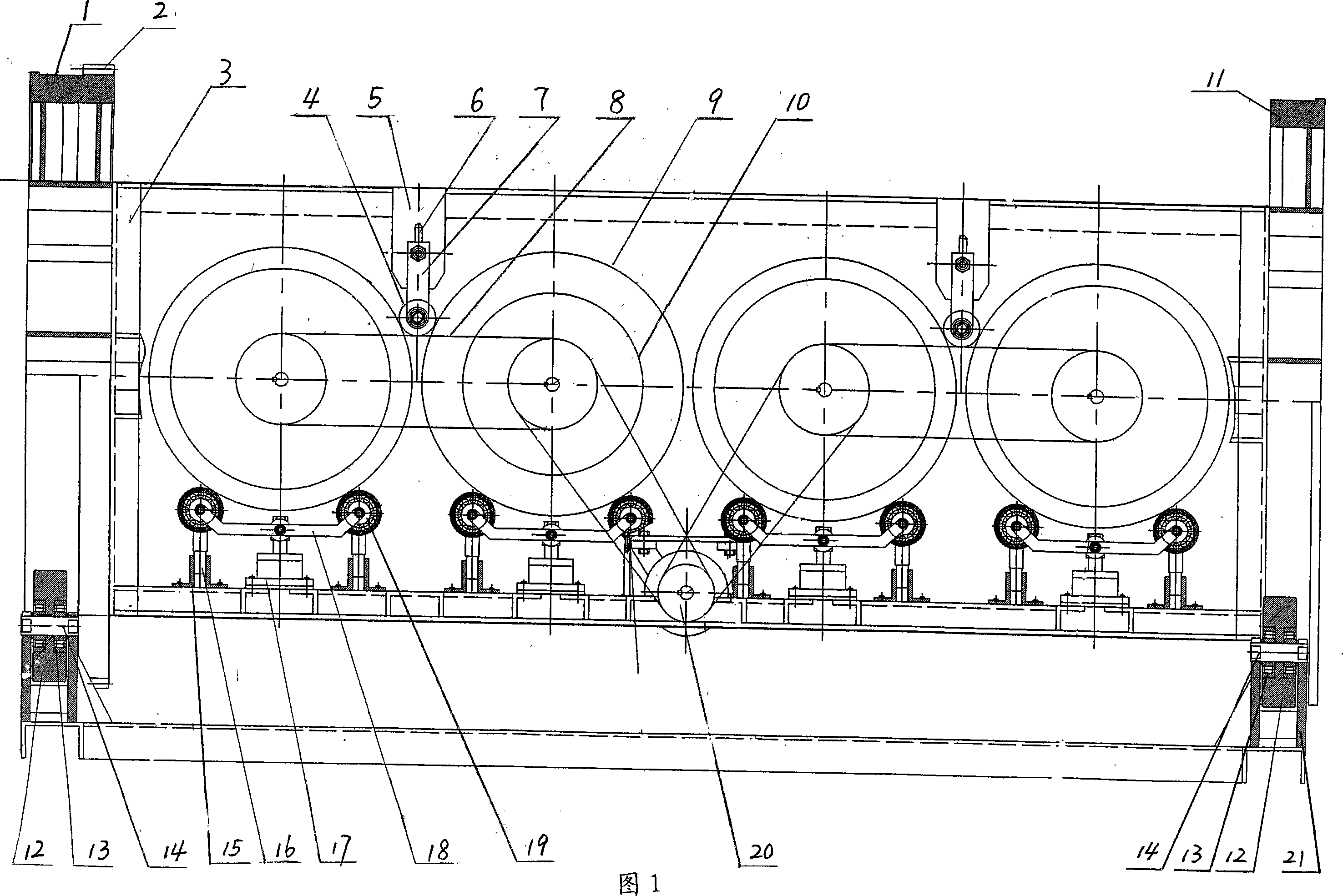

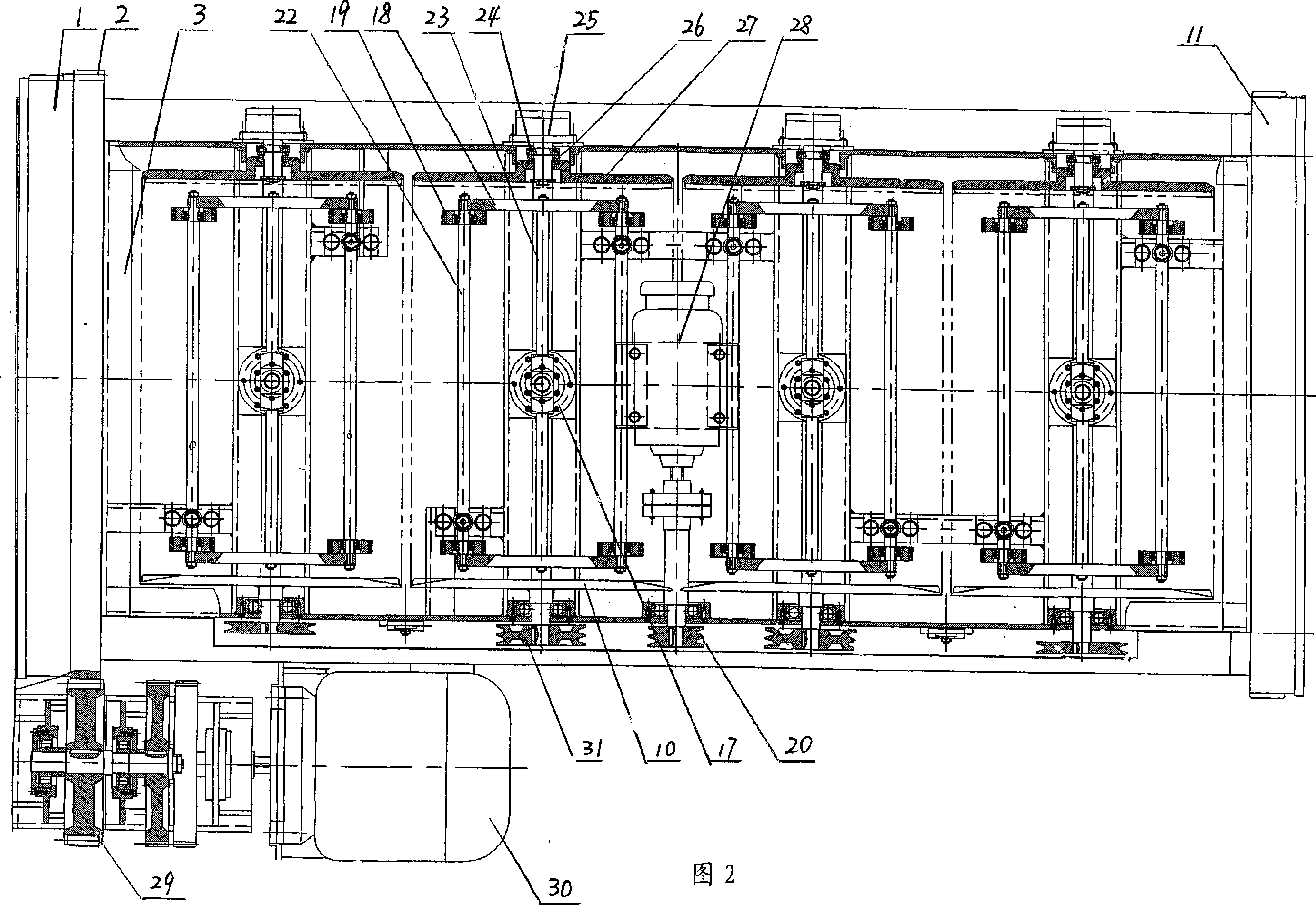

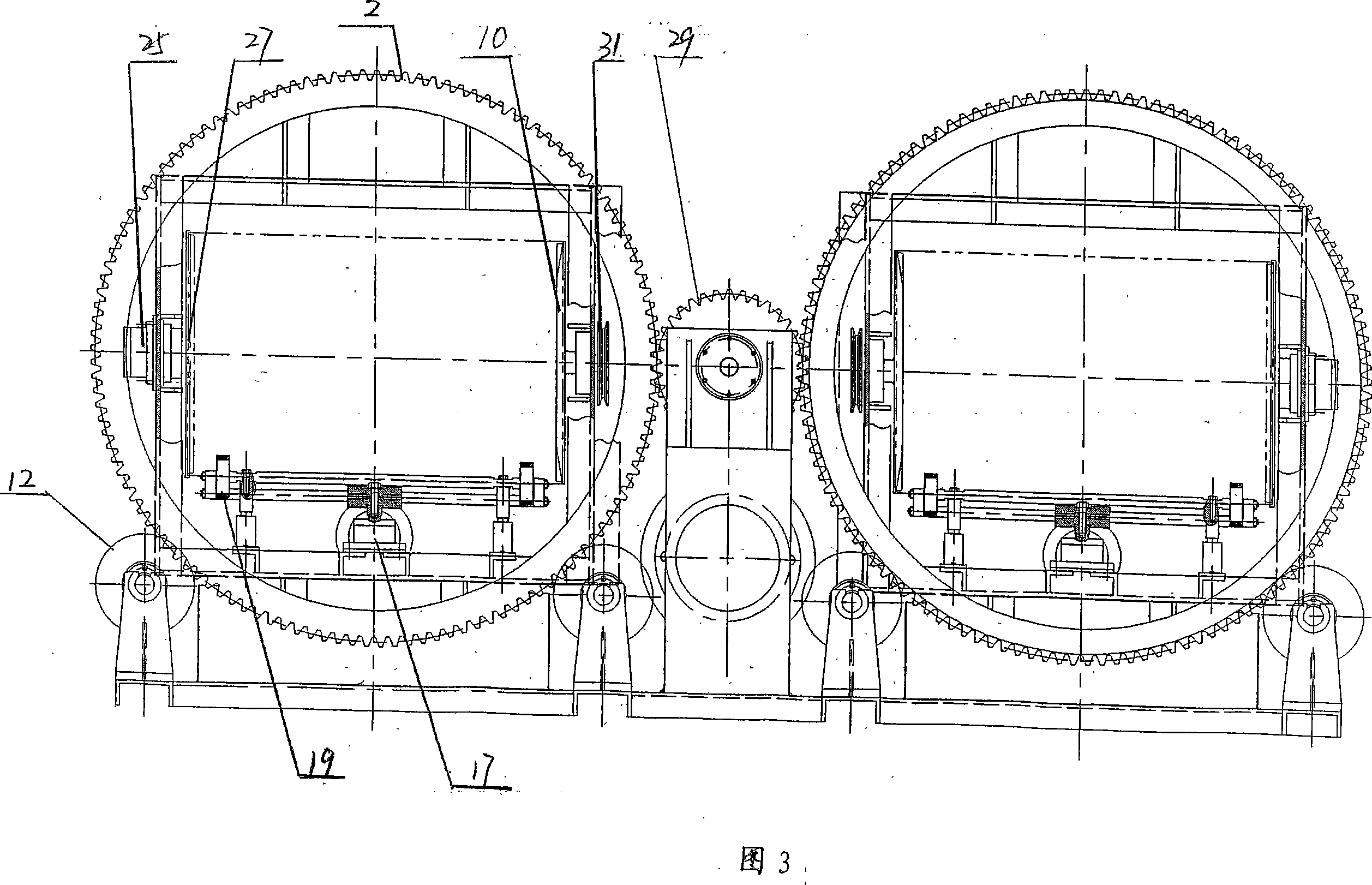

[0017] The closed bucket scrubbing device of the present invention comprises a swing motor 30 and at least one group of workbenches 3, the front view is as shown in Figure 1, and Figure 2 is a schematic diagram of a closed bucket scrubber with one group of workbenches, and Figure 3 is a schematic diagram with a closed bucket scrubber with one group of workbenches The left side view of the closed bucket scrubbing device of two groups of workbenches, the two ends of each workbench 3 are respectively connected with support sleeves 1, 11, and the underside of each support sleeve passes through the brackets 21, 11 fixed on the base respectively. Axle 14, bearing 13 are provided with the support wheel 12 of free rotation, and the support sleeve of one end is connected with swing motor by transmission mechanism and reduction mechanism. The above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com