Method of preparing photosensitivity multipolymer doped with optical-fibre preformed bar and the fiber core material

A technology of doping optical fibers and copolymers, which is applied in optics, light guides, optical components, etc., can solve the problems of insufficient height, serious dye diffusion, and lower refractive index of the fiber core, so as to avoid diffusion, stabilize the polymerization reaction, and increase the doping concentration. The effect of increasing the upper limit of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0043] 1. Experimental reagents

[0044] Dimethylformamide (DMF) (AR, Sinopharm Chemical Reagent Co., Ltd.), AIBN (CP, Shanghai Shihewei Chemical Co., Ltd.), methyl methacrylate (AR, Tianjin Bodi), butyl acrylate ( AR, Tianjin Bodi), the above reagents were refined before use. 2-[4-(4-cyanoazophenyl) phenoxy] ethyl methacrylate (self-made, denoted as MCN2), methanol (AR, Sinopharm Chemical Reagent Co., Ltd.),

[0045] 2. Synthesis of azo copolymer (denoted as PCN2)

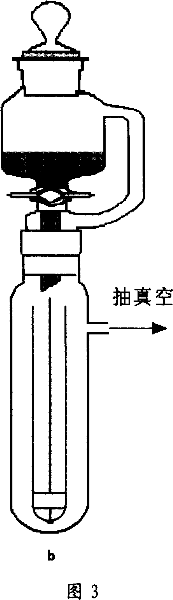

[0046] Weigh 0.5024g of monomer MCN2 and dissolve it in 10ml of DMF, then add 1ml of methyl methacrylate, add an appropriate amount of initiator 5% AIBN (molar percentage), and then carry out locked tube polymerization, the polymerization temperature is 70 ° C, and the polymerization time is 72 hours . After the reaction is over, break the sealed tube and pour the reaction solution into a large amount of methanol solution. After the product precipitates, filter it out and dry it, then dissolve it in as little T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com