Balancing a nipper mechanism in a combing machine

A combing machine and nipper shaft technology, applied in the direction of combing machine, textile and paper making, fiber processing, etc., can solve the problem of additional maintenance of the device, and achieve the effect of full clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

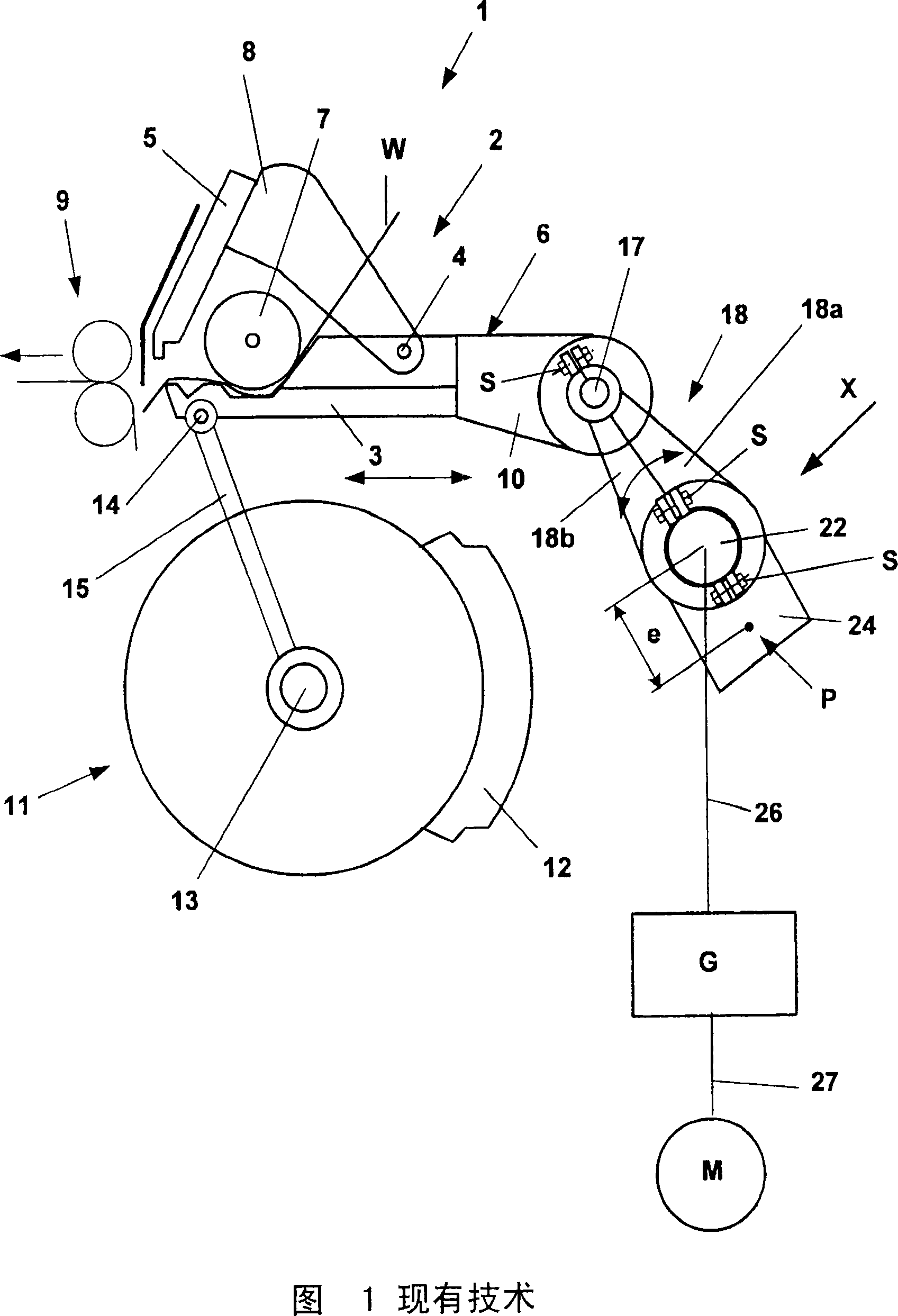

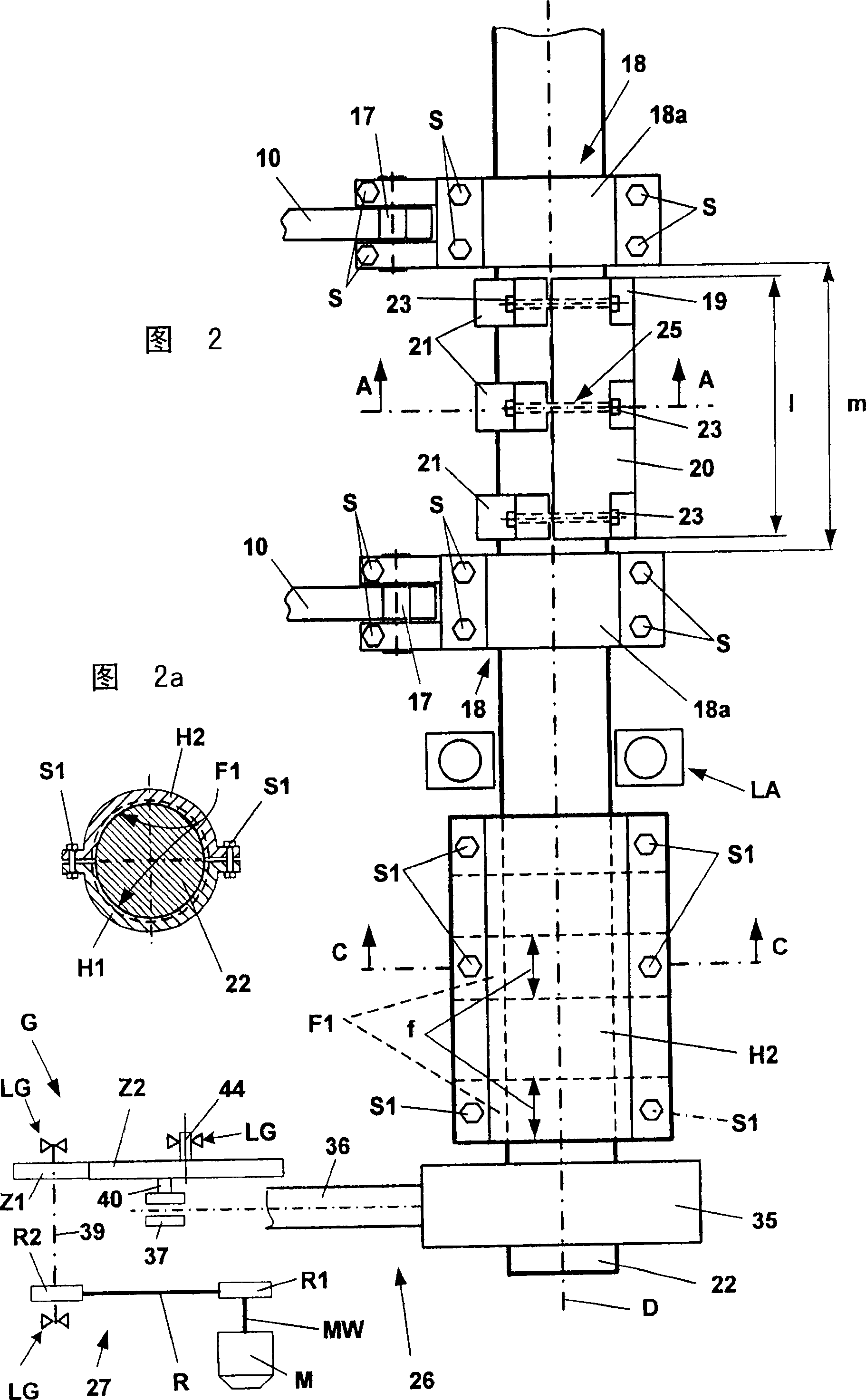

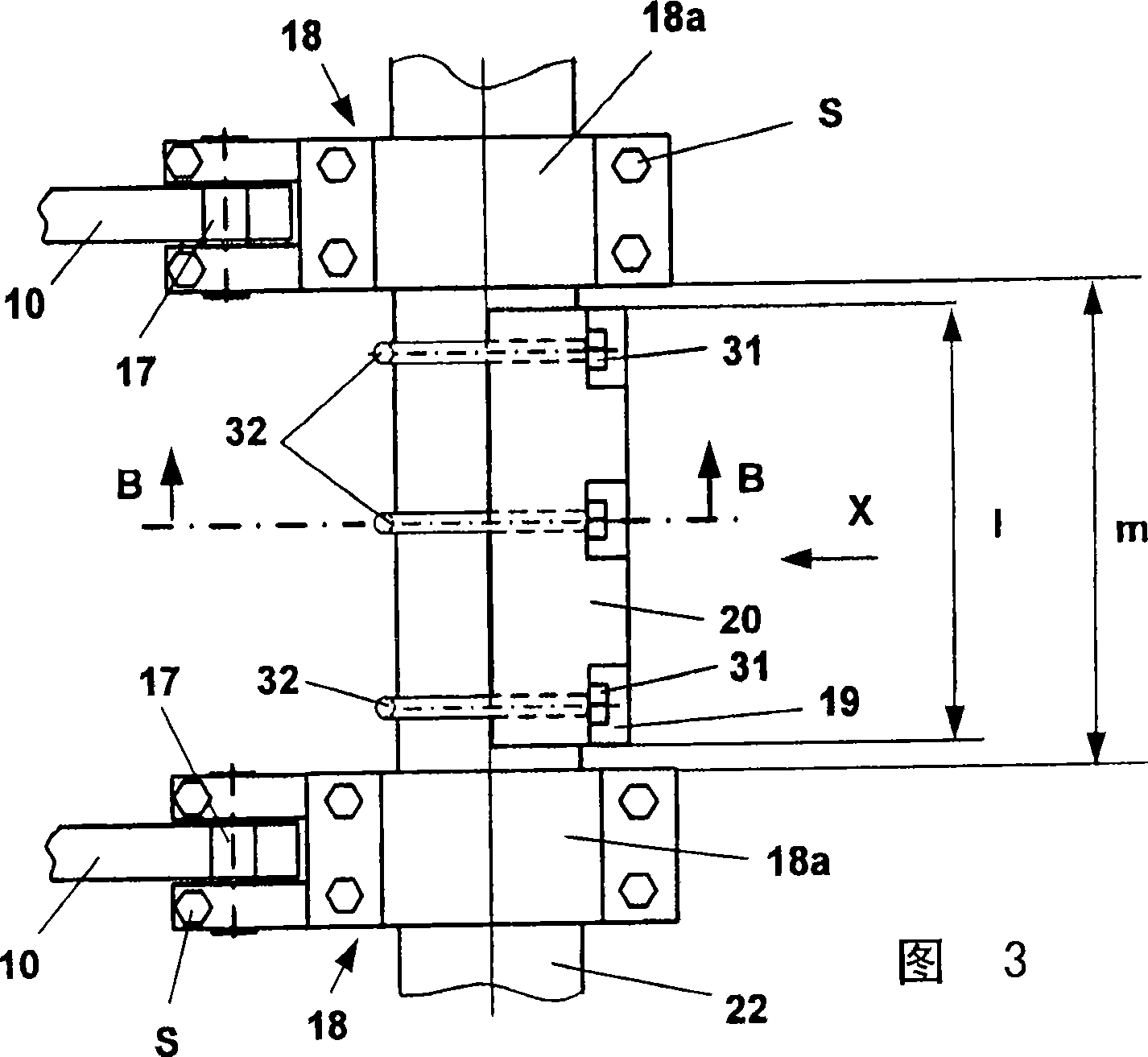

[0036] Fig. 1 schematically shows the structure of a combing head 1, which has a nipper assembly 2 provided with a lower nipper 3 and an upper nipper 5 pivotally mounted on the lower nipper around a rotation axis 4. The nipper 5 is in this case connected to two pivot arms 8 which are pivotally mounted on the swivel axis 4 . The lower nipper 3 is fixed in the nipper mount 6 . A rotatably mounted feeding cylinder 7 is arranged above the lower nipper 3, which conveys or feeds lap sheets W supplied by laps not shown in the direction of the detaching roller 9 arranged downstream at regular intervals .

[0037] In the illustrated embodiment, the nipper assembly 2 is in the front position in which it is open and performing splitting and splicing operations. On the nipper mount 6, pivoting arms 15 are mounted rotatably on both sides in the region of the lower nipper 3, in each case on the shaft 14, and at their other end at the end of the circular comb 11. on axis 13. For the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com