Automatic moving clerestory window

A technology for moving and pulling skylights, which is applied to roofs, buildings, building structures, etc. It can solve the problems that skylight equipment cannot be opened and closed automatically and the degree of opening and closing, lack of window automation, and manual opening and closing of skylights is inconvenient. Achieve the effect of simple structure, easy assembly and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

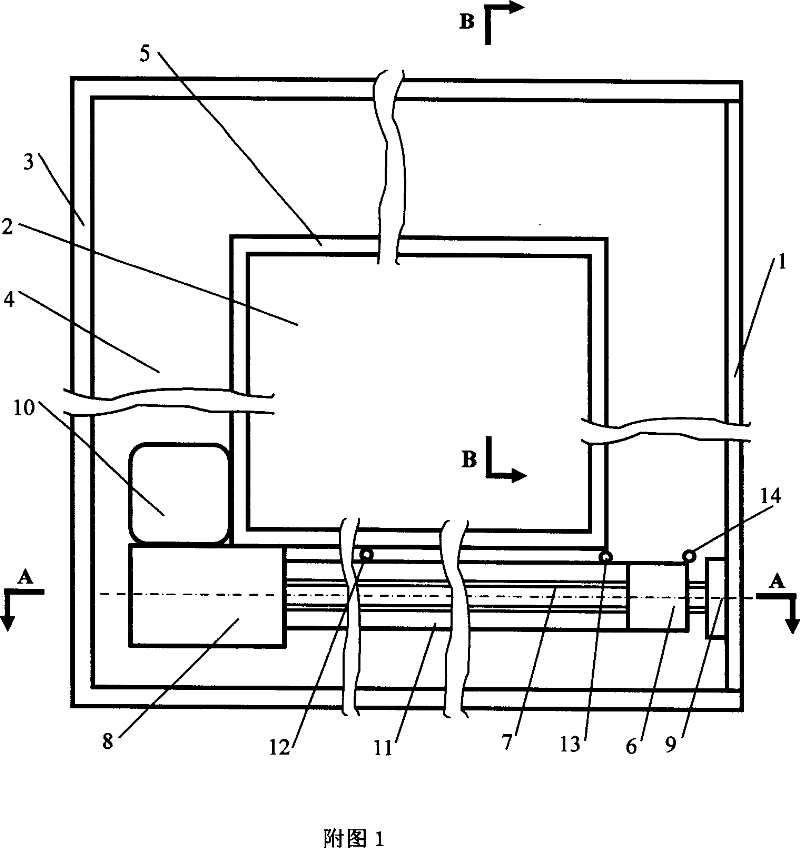

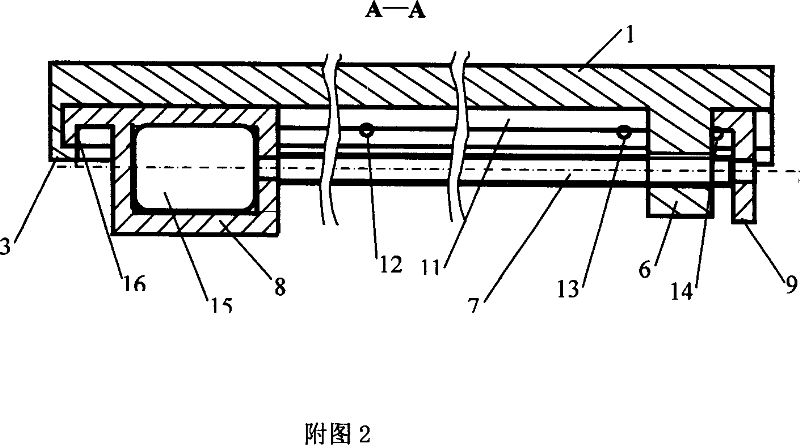

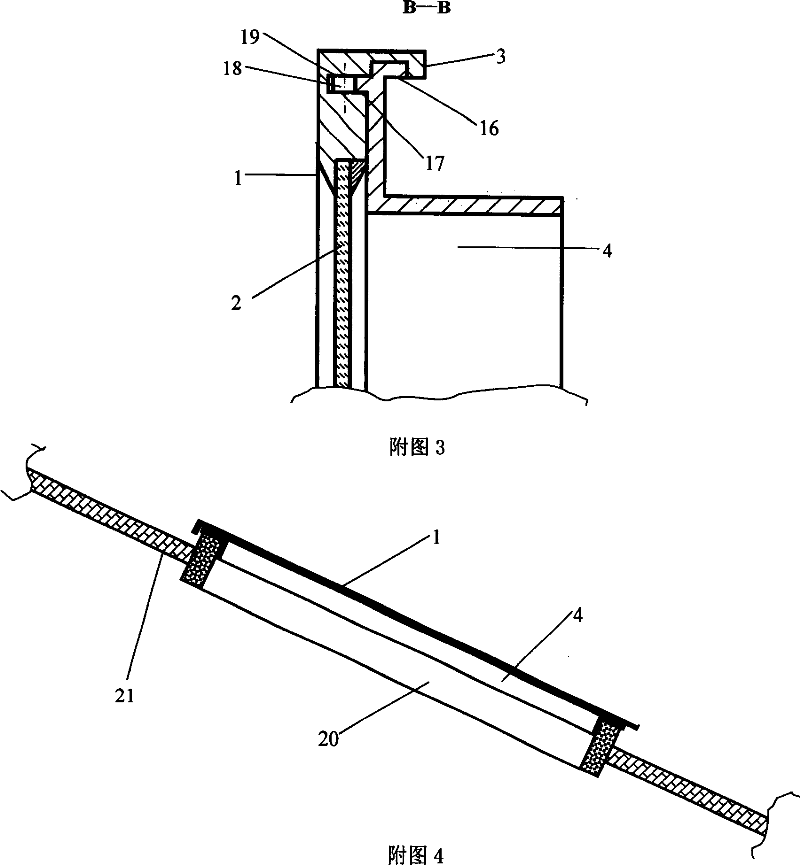

[0014] In the embodiment shown in the drawings, the sliding window sash composed of the outer frame (1) tightly embedded with glass (2) is assembled on the fixed window frame (4) with slide rails (17). Controlled and driven by the control system, the motor (15)-screw (7)-screw nut (6) mechanism drives the sliding. Move and pull the left and right sides of the sash frame (1) to make a groove (19) along the edge, and the groove is embedded with a pulley (18) that leans on the fixed window frame slide rail (17) to roll; the left side of the frame (1) , the outer edge of the right side and the uplink side are downward, and then vertically folded inward twice to form a rainproof and pry-proof edge (3). The left and right sides of the fixed window frame (4) are made on the top slide rail (17) along the edge convex shoulder that is rollingly matched with the pulley (18) in the sash frame (1) groove (19); the fixed window frame ( 4) The left, right and upside outer edges are vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com