Transportable plastics recovery system

A transportation system and plastic technology, applied in the field of recycling of plastics, metals and other materials, can solve the problems of inability to achieve high bulk density, damage to crushing equipment, large particle size, etc., to avoid excessive metal pollution, fast turnover, easy transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

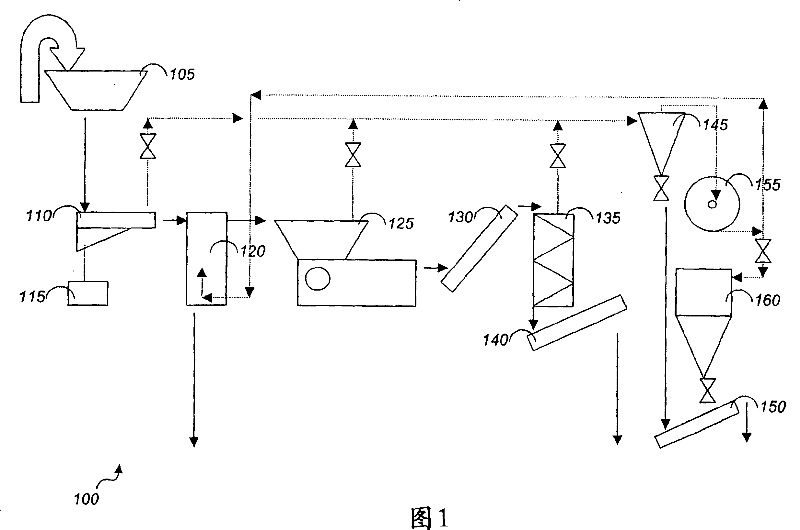

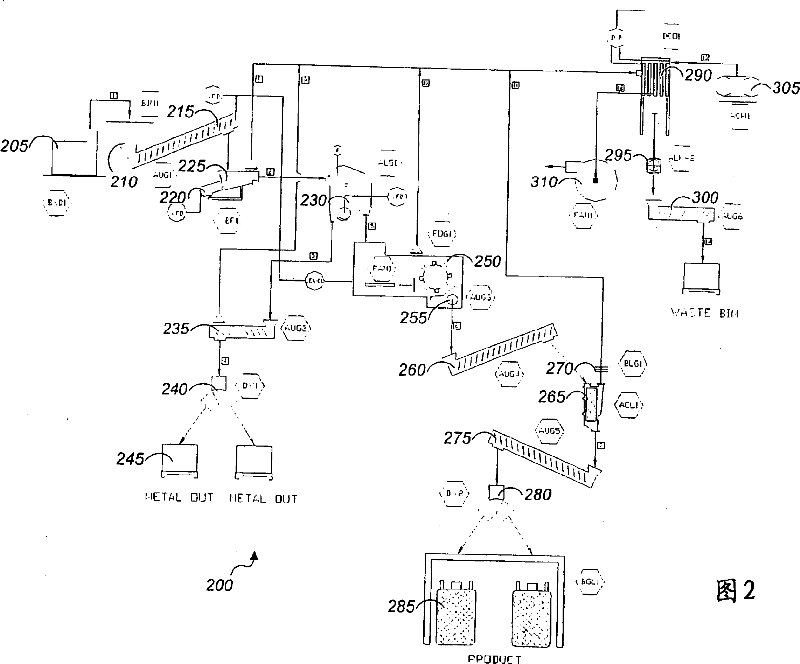

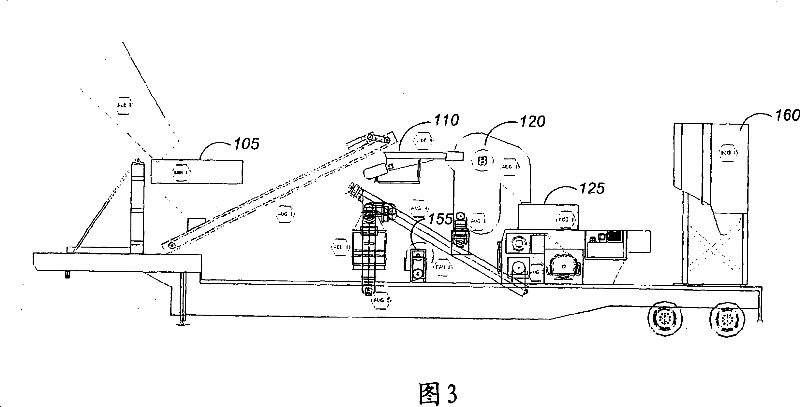

Method used

Image

Examples

example 1

[0047] Example 1: Metal removal using an aspirator and grinding system

[0048] Plastic-rich shredded material from printer cartridges and from appliances both contain high levels of metals. The two materials were separated by passing through an air hammer separator manufactured by American International Manufacturing Corporation (Woodland, CA), followed by size reduction in a rotary mill.

[0049] Table 1 shows the percentage of metal rejected in each stream versus the heavy stream of the air hammer separator, and the percentage of total plastic lost in the process. For both material streams, the hammer separator removed most metals with no appreciable loss of plastics.

[0050] Printer Cartridges

example 2

[0051] Example 2: Using suction to remove large pieces of metal

[0052] Coarsely crushed plastic-rich material from the appliance is processed through a pneumatic hammer separator. The separator is tuned to remove nearly all large metal (defined as any size greater than 25mm) that could compromise milling while minimizing loss of plastic.

[0053] Table 2 shows the removal efficiency of large and small pieces of metal. The data show that almost all of the large metals were removed, while only a fraction of the small metals were removed, and very little plastic.

[0054] Percentage of large metals in total metals

example 3

[0055] Example 3: Grinding after pumping to increase bulk density

[0056] Using a pneumatic hammer separator, the coarsely comminuted plastic-rich material from the appliance is first separated into "light" and "heavy" streams. The "light" material was passed through a grinder with a 25.4 mm (one inch) screen.

[0057] Table 3 shows the bulk density of the feed, the "heavy" by-product and the ground "light" product. Bulk density is calculated by weighing the amount of material in the tank and determining the volume by measuring the height of the material filling the tank. In this case the feed does not contain most of the fluff and debris, so it is expected that there will be no bulk density change from the pump down stage of the subsequent milling. The ground "light" product has a higher bulk density than the feed or "heavy" by-product.

[0058] flow

Bulk density (kg / m 3 )

Feed

331

"Heavy" by-products

352

Abrasive "lightweight"...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com