Self-clean film material and preparation method

A thin-film material and self-cleaning technology, applied in metal material coating process, paper coating, fiber raw material processing, etc., can solve the problems of difficulty in depositing fluorocarbon film, high vacuum cost, etc., achieve far-reaching use value, low equipment cost, high flow rate low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

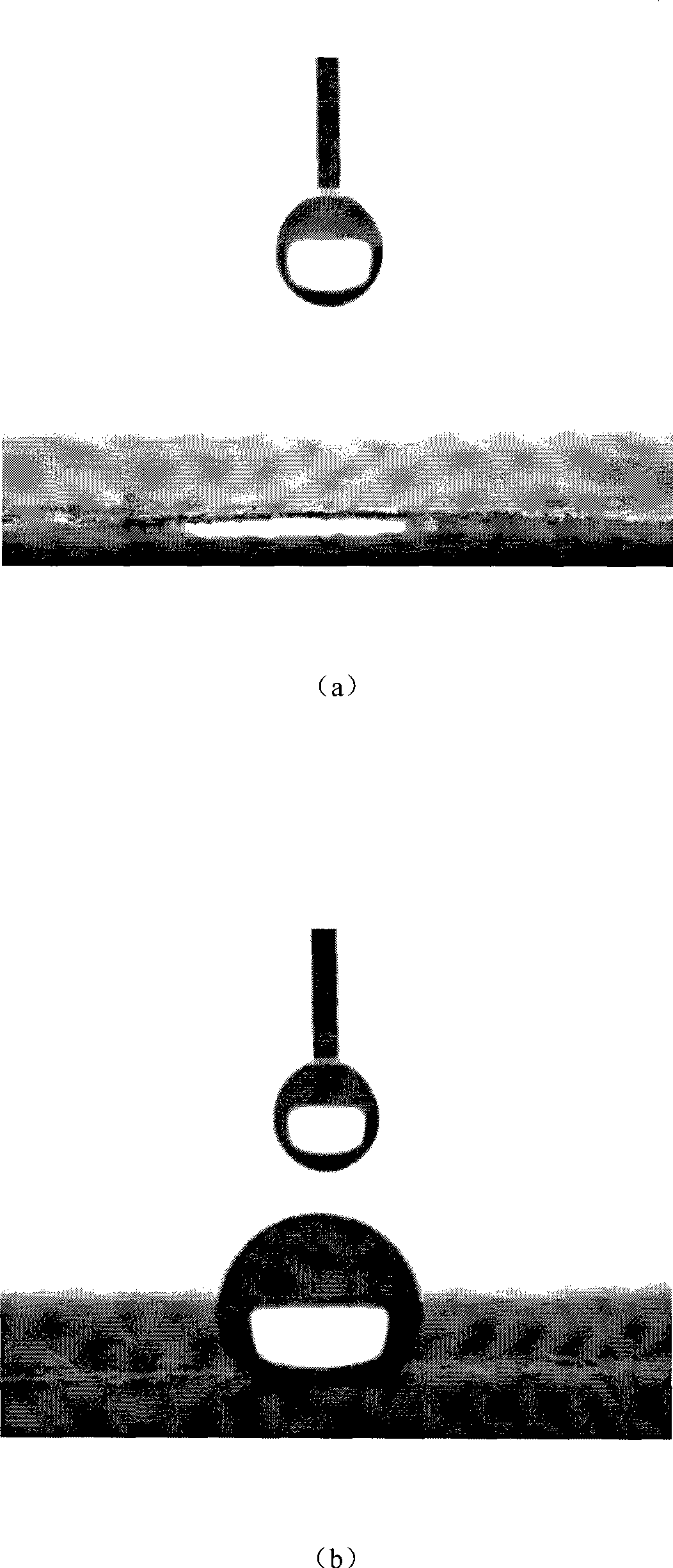

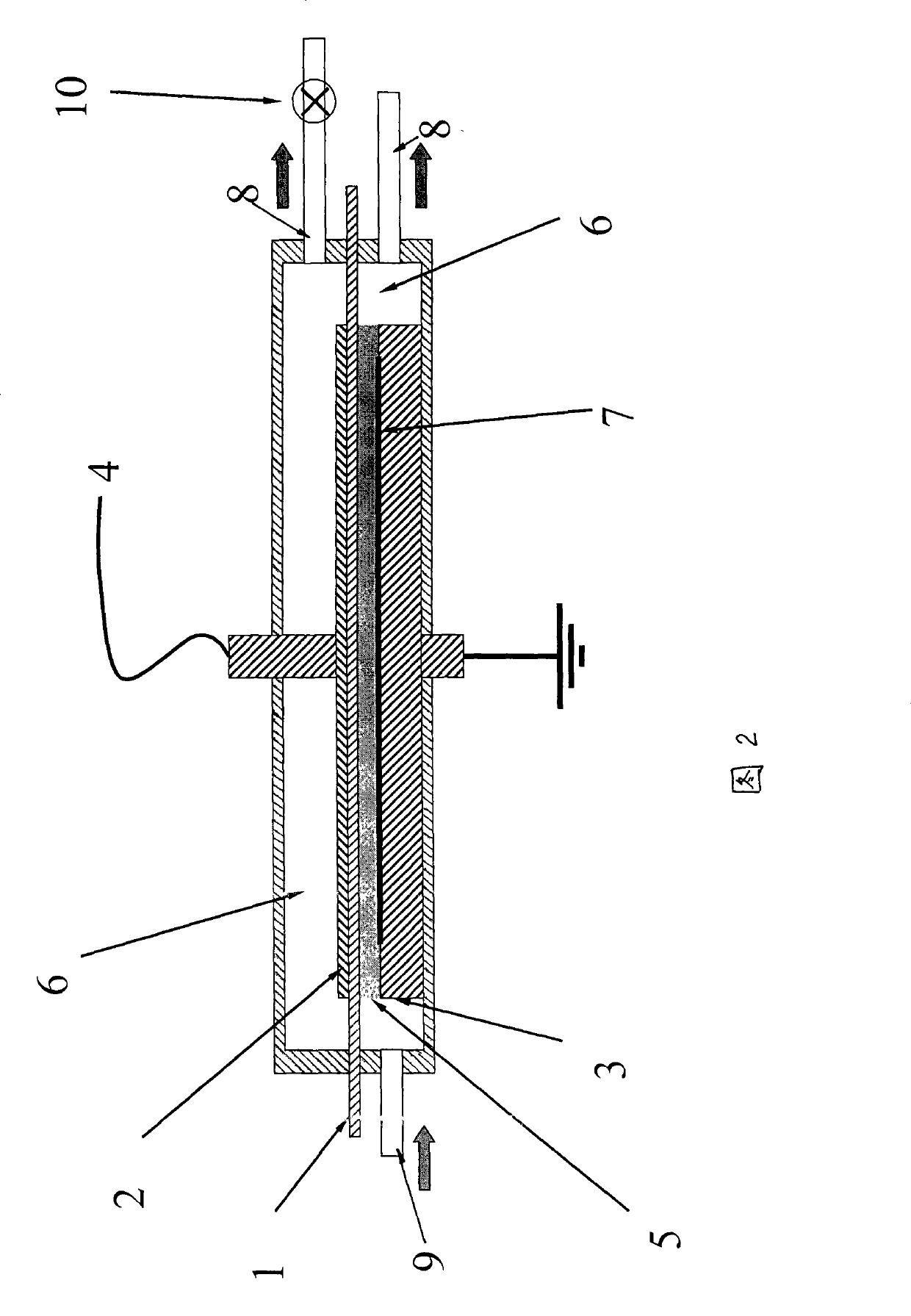

[0019] prepared as figure 1 The self-cleaning film paper shown in figure 2 In the deposition device of the fluorocarbon film shown, the two symmetrical vacuum chambers 6 separated by the insulating material glass 1 are equipped with exhaust ports 8, and the high-voltage electrodes 2 and the ground electrodes 3 are respectively installed in the vacuum chambers, and the paper 7 is placed in Between the high-voltage electrode and the ground electrode, the paper is in contact with the surface of the ground electrode or the paper is placed on the glass, and there is a gap between the paper and the high-voltage electrode. There is an air inlet hole 9 on the vacuum chamber with the ground electrode.

[0020] When depositing fluorocarbon film on paper, the high-voltage power supply is connected to the high-voltage electrode by wire 4 to provide AC near-sine wave high voltage. The peak-to-peak voltage must reach more than 20kV, and the frequency is 1KHz. There are two symmetrical vac...

Embodiment 2

[0022] Adopt the equipment described in embodiment 1 to carry out fluorocarbon film deposition on the glass surface, the high-voltage power supply is connected to the high-voltage electrode by the wire 4 to provide the AC near sine wave high voltage, the peak-to-peak voltage must reach more than 30kV, the frequency is 2KHz, and the two sides of the glass 1 are provided by two The exhaust ports of two symmetrical vacuum chambers are connected to a mechanical pump at the same time. When exhausting, the two vacuum chambers must be exhausted at the same time to avoid the glass from being broken due to pressure imbalance on both sides. Before discharging, the cut-off valve 10 must be closed to prevent the high-voltage electrode from generating plasma in the exhaust port. Before deposition, use helium as the discharge gas, which is fed through the gas inlet 9, and discharge treats the glass surface for about 10 minutes, so as to improve the adhesion between the substrate surface and ...

Embodiment 3

[0024] Adopt the equipment described in embodiment 1 to carry out fluorocarbon film deposition on polyester surface, high-voltage power supply is connected with high-voltage electrode by wire and provides alternating current near sine wave high voltage, and the peak-to-peak voltage must reach more than 30kV, frequency 2KHz, polyester both sides by two The exhaust ports of two symmetrical vacuum chambers are connected with a mechanical pump at the same time. When exhausting, the two vacuum chambers must be exhausted at the same time to prevent the two sides of the polyester from being broken due to pressure imbalance. Before discharging, the cut-off valve must be closed to prevent the high-voltage electrode from generating plasma in the exhaust port. Before deposition, use argon as the discharge gas, pass it through the gas inlet, and discharge the polyester surface for about 8 minutes, so as to improve the adhesion between the substrate surface and the film. then use C 2 f 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com