Delivery pipe for transporting solid materials and method for producing a delivery pipe

A technology for conveying pipes and solids, applied in the field of conveying pipes, can solve the problems of shortened service life and operation interruption, and achieve the effect of improving service life, prolonging service life and uniform stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

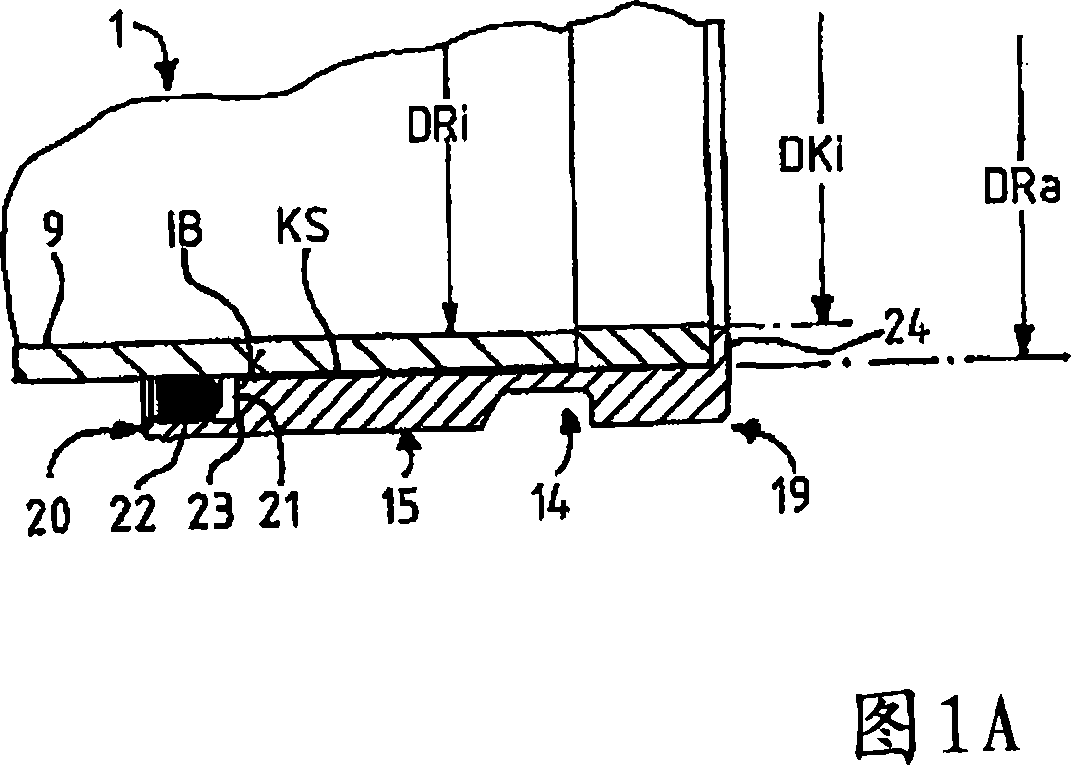

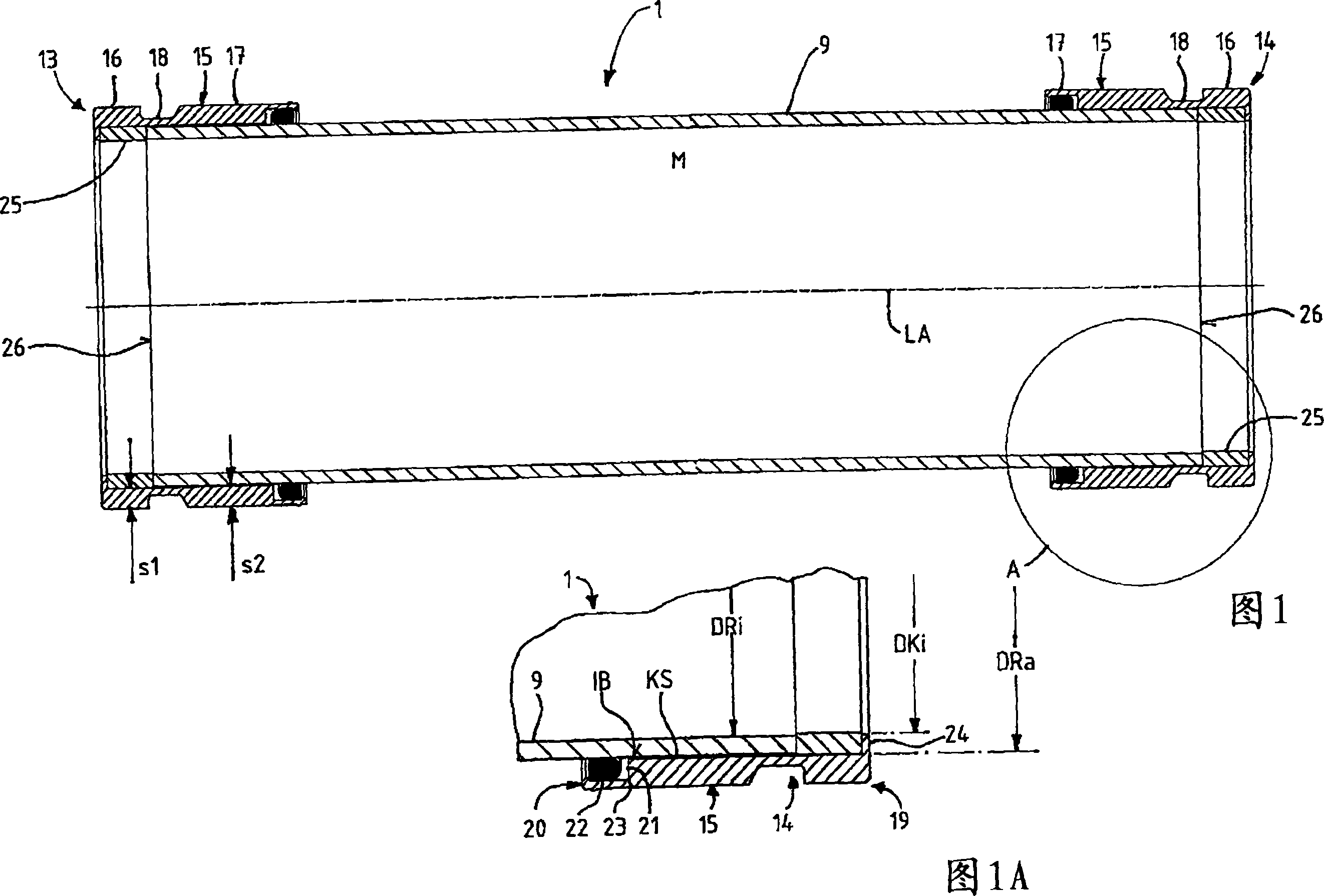

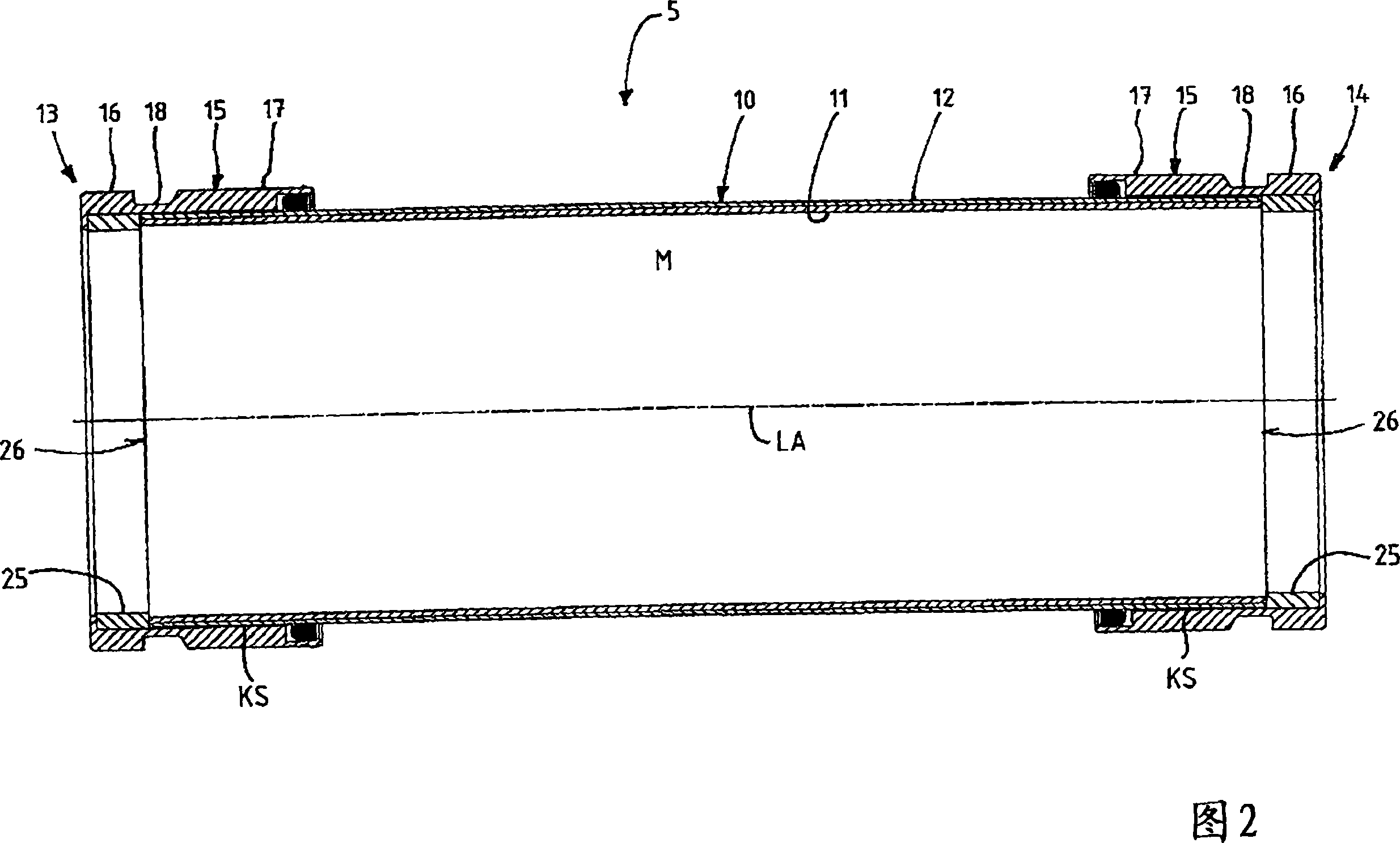

[0029] In Figures 1, 3, 5 and 7 a single layer embodiment of the delivery pipes 1, 2, 3, 4 is shown, in contrast to this Figures 2, 4, 6, 8 show the delivery pipes 5, 6, 7, 8 double layer implementation.

[0030] The delivery pipes 1 , 2 , 3 , 4 have a single-layer pipe body 9 made of highly wear-resistant hardened steel. In contrast, the delivery pipes 5 , 6 , 7 , 8 are designed as a double-layer pipe body 10 consisting of a highly wear-resistant hardened inner pipe 11 and a pressure-resistant outer pipe 12 .

[0031] A connecting ring 15 is fastened to each end 13, 14 of the tubular bodies 9 and 10 by a full-surface adhesive bond. The connecting ring 15 , viewed in the direction of the longitudinal tube axis LA, has a first ring section 16 on the end side and a second inner ring section 17 pointing towards the tube center M, between which a trapezoidal coupling groove 18 is formed. . It can be seen that the wall thickness s1 of the first ring segment 16 is smaller than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com