Movable type forming machine for U type trench wall

A mobile and forming machine technology, which is applied in the direction of ceramic forming machines, ceramic extrusion dies, manufacturing tools, etc., can solve the problems of weak structure, high cost and easy damage of the canal wall, and achieve simple structure, resource saving, cleverly conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

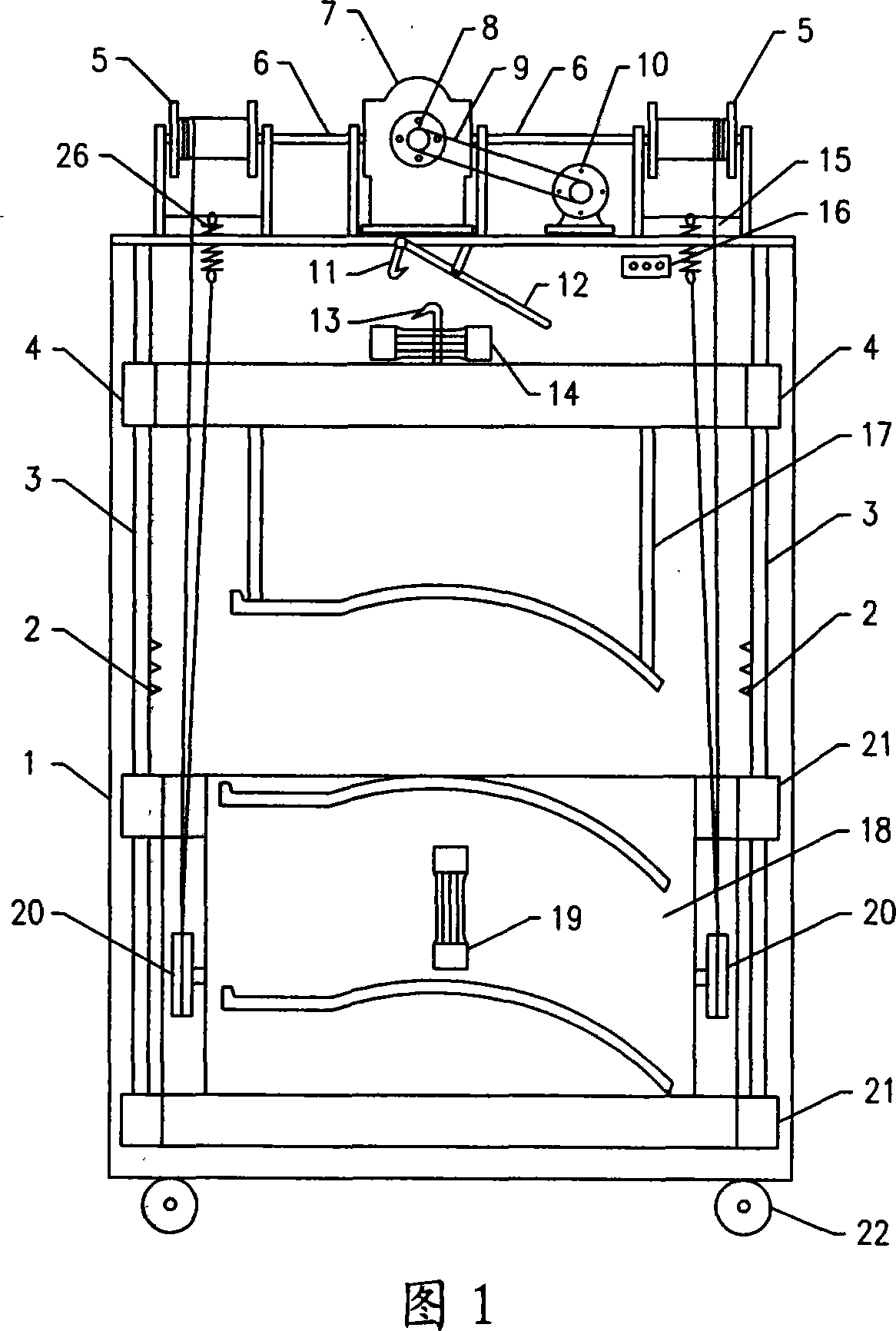

[0009] Among Fig. 1, the upper end of frame 1 is provided with motor 10, and the left end of motor is equipped with reduction box 7, and the left and right two outsides of reduction box are provided with winch 5, and the lower side of winch is equipped with lifting spring 26, and the inboard of winch is provided with connection. A shaft joint, the left and right ends of the reduction box are provided with a drive shaft, the drive shaft is respectively equipped with a connecting shaft 6, and the two ends of the connecting shaft 6 are respectively installed and connected to the connecting shaft head of the hoist. The front end of reduction box is provided with belt pulley 8, and drive pulley is housed on the motor, and drive belt 9 is housed on reduction box pulley and motor drive pulley. The left and right sides of the frame are equipped with guide shafts 3, and the frame on the lower side of the reduction box is provided with an upper mold 17 and a lower mold 18. The upper mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com