Label inside composite membrane

An inner label and composite mold technology, applied in synthetic resin layered products, stamps, seals, etc., can solve the problems of difficult exhaust, unsatisfactory bonding effect, and poor bonding between labels and molded products, so as to improve product quality. , The effect of improving the wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

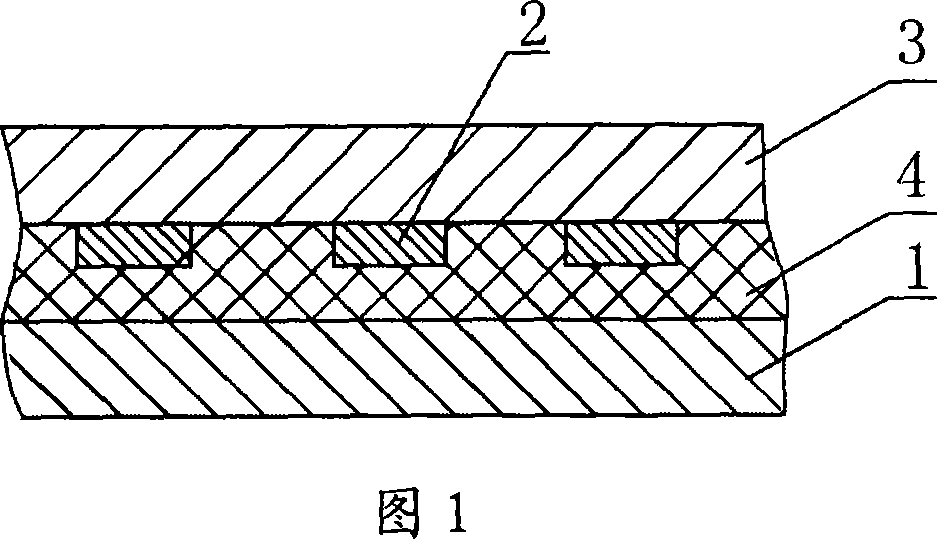

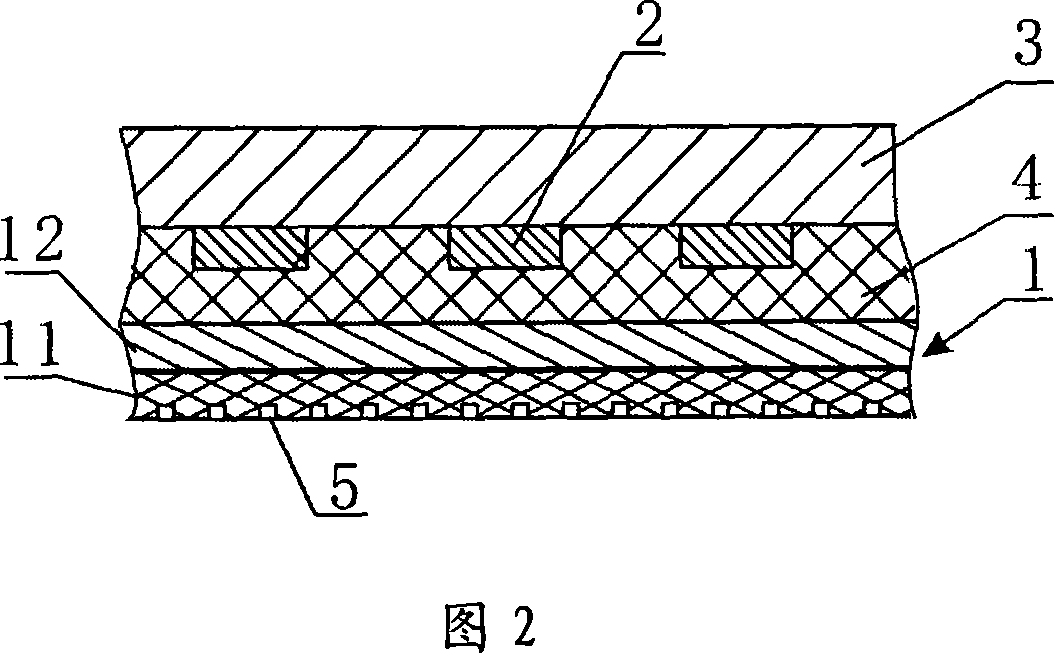

[0023] The composite in-mold label of the present invention as shown in FIG. 2 is composed of a base film layer 1 , an ink layer 2 and a transparent coating layer 3 . Wherein the ink layer 2 constitutes the pattern or text of the label, which is printed on the inner side of the transparent coating layer 3 . The base film layer 1 and the transparent coating layer 3 are bonded together by a strong composite glue 4 . Of course, the base film layer 1 and the transparent coating layer 3 can also be compounded together by other compounding methods such as extrusion compounding, dry compounding or solvent-free compounding.

[0024] Wherein the transparent coating layer 3 may be a BOPP film, a BOPET film or a BOPA film. These films allow the resulting labels to be stiff, scratch-resistant and abrasion-resistant.

[0025] The ink layer adopts sun-resistant, alkali-resistant and heat-resistant ink.

[0026] The base film layer 1 adopts a layered structure consisting of at least two l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com