Method for tightening main cable of new type suspension bridge

A suspension bridge and cable technology, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of zinc layer falling off, messy wires, and cable strand crossing, so as to avoid zinc layer falling off and reduce packaging costs , the effect of reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

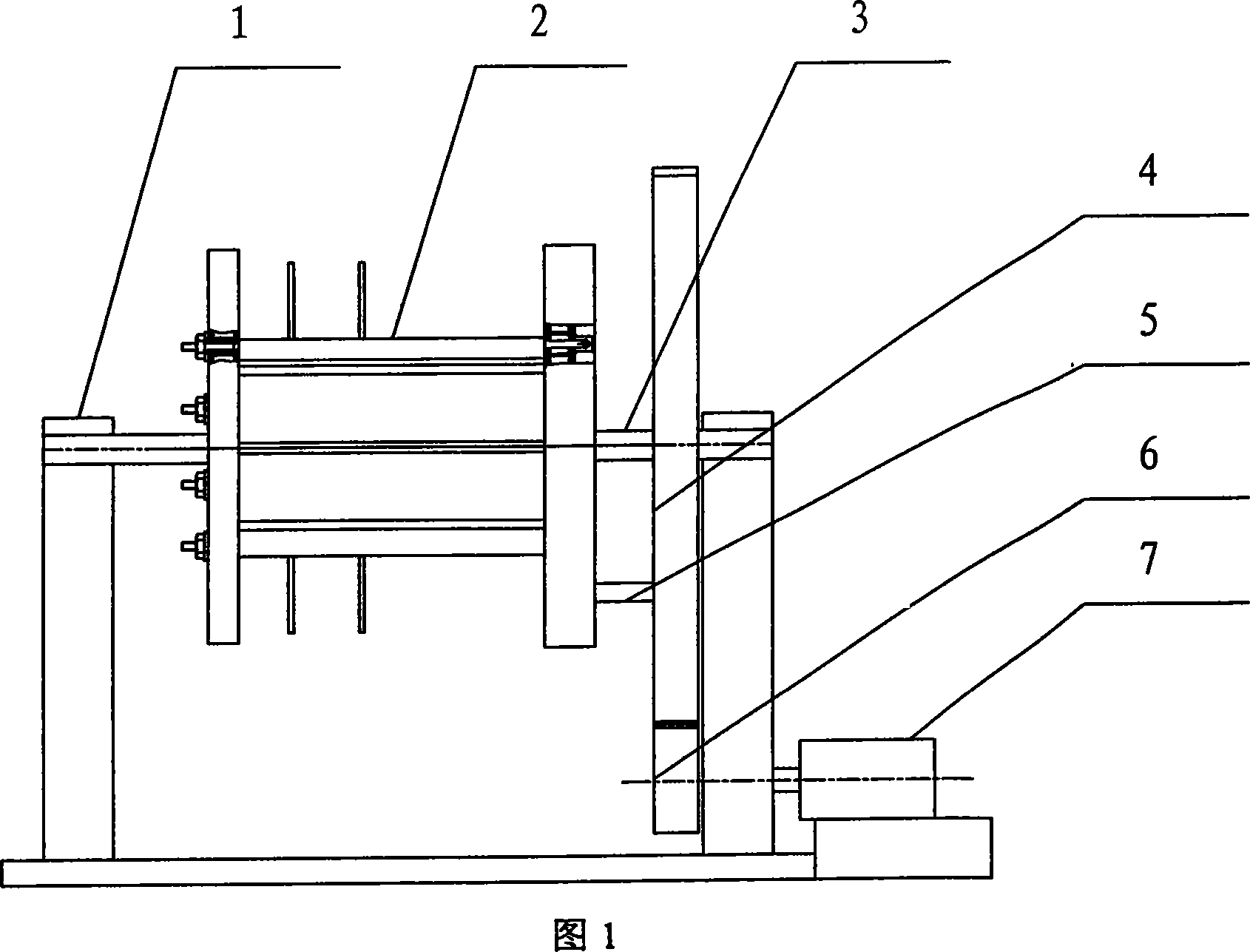

[0020] Referring to Fig. 1, Fig. 1 is that the present invention adopts a kind of main cable unit of suspension bridge, mainly consists of support 1, combined steel plate 2, transmission central shaft 3, large gear shaft 4, dial pin 5, pinion 6 and motor 7 composition. The transmission center shaft 3 is horizontally installed on the bracket 1, and the combined steel plate 2 is set on the transmission center shaft 3; the output end of the motor 7 is connected with the pinion 6, and the pinion 6 meshes with the bull gear 4, and the bull gear 4 is fixedly connected to the transmission center shaft 3, one end of the dial pin 5 is installed inside the gear wheel 4, and the other end is inserted into the combined steel plate 2.

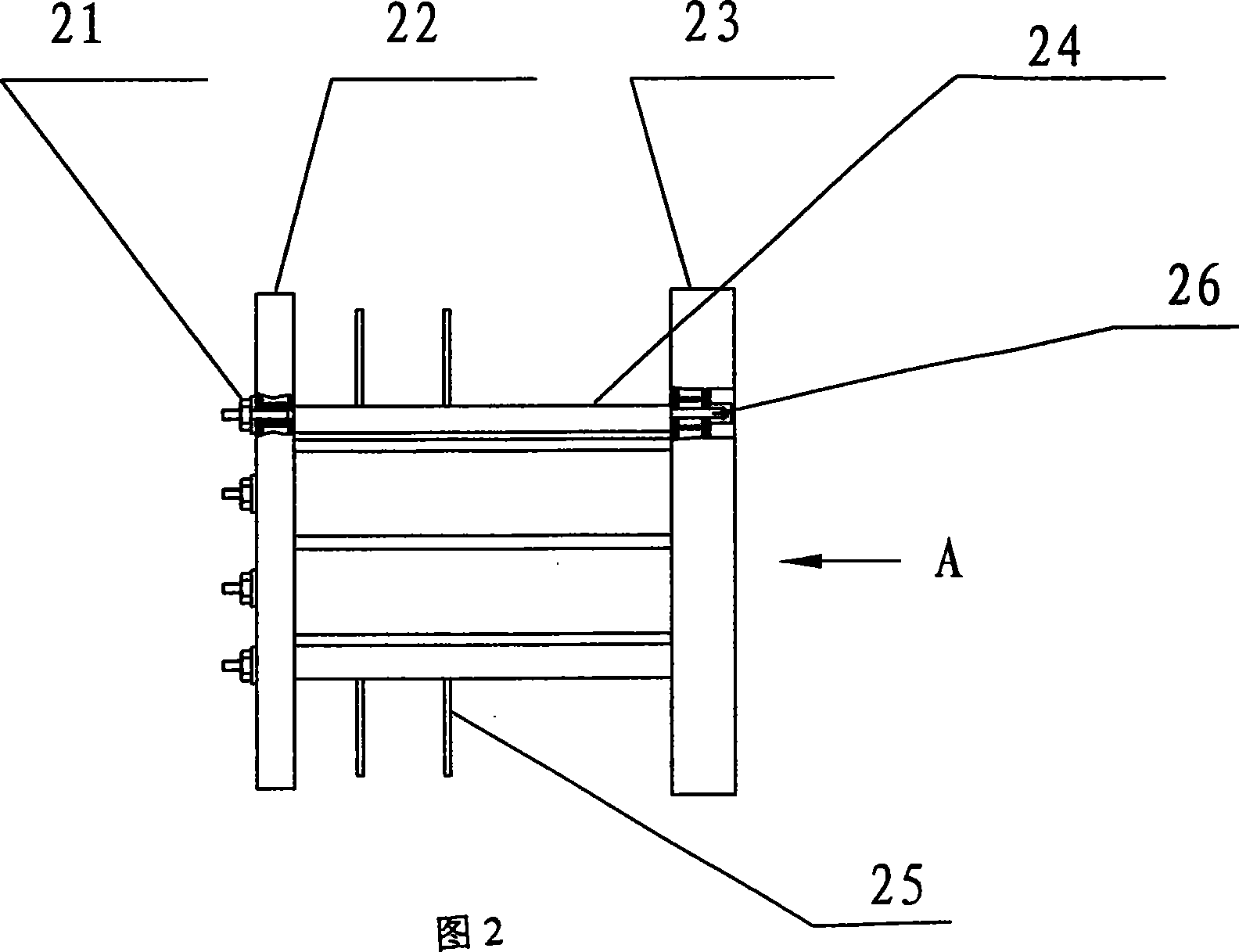

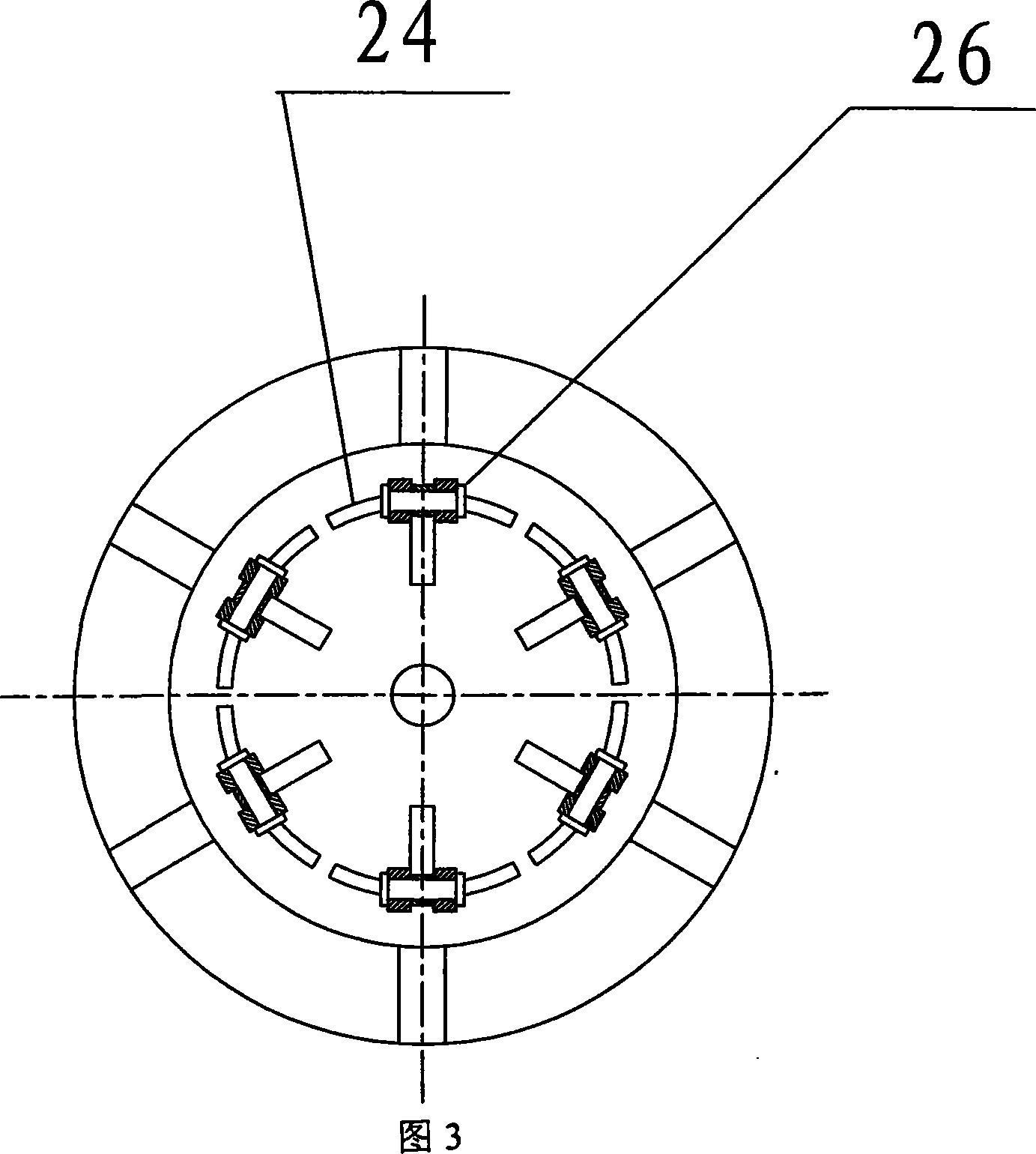

[0021] Referring to FIGS. 2-3 , the combined steel plate 2 is mainly composed of anchor bolts 21 , front cover 22 , rear cover 23 , arc-shaped plate 24 , isolation column 25 and latch 26 . Described arc-shaped plate 24 has several sheets (there are 6 among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com