Online sterilization method and device for filling pipeline

A technology of a sterilization device and a sterilization method, applied in the directions of packaging sterilization, packaging, packaging machines, etc., can solve the problems of time-consuming, labor-intensive, troublesome operation, etc., and achieve the effects of simplified structure setting, simple structure and high sterilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

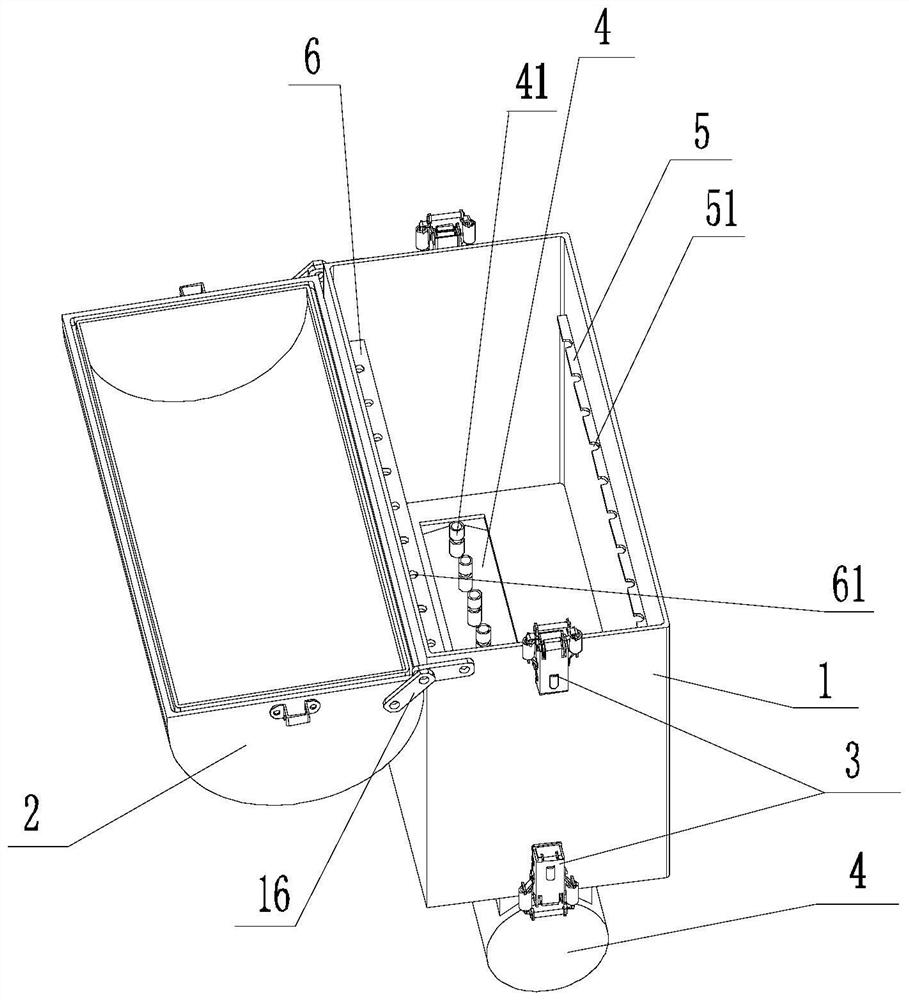

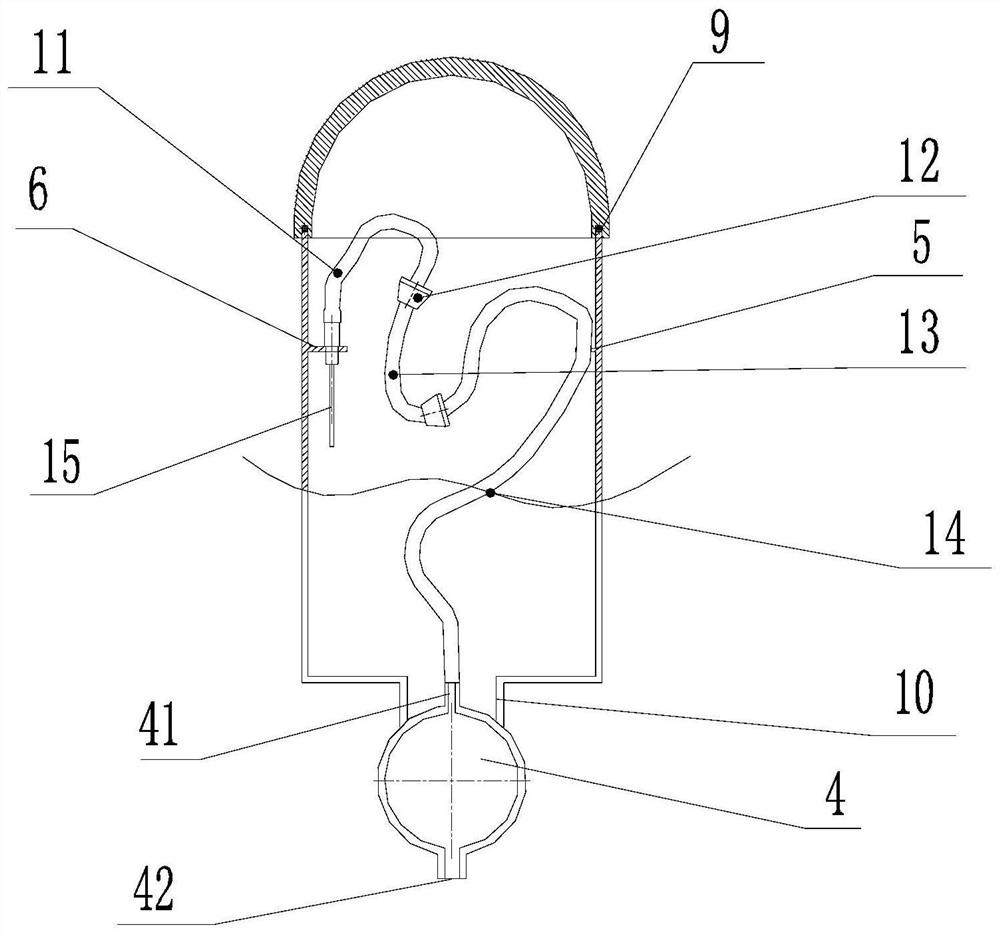

[0045] Such as figure 1 and figure 2 , Figure 4 and Figure 5 As shown, the online sterilization device for filling pipelines of the present invention is used to implement the above-mentioned online sterilization method for filling pipelines, and includes a pressure-resistant airtight chamber. Further, the pressure-resistant airtight chamber includes: cavity 1 , the cover body 2 and the liquid separator 4; the top and bottom ends of the cavity body 1 are connected, and the top end of the cavity body 1 and the cover body 2 are detachably sealed and connected by fasteners; the bottom end of the cavity body 1 is provided with The outwardly extending boss 10 is detachably sealed with the dispenser 4 through fasteners; when in-line sterilization is performed, the pipeline components of the filling system are placed in a pressure-resistant airtight chamber, The circuit assembly inputs the high-pressure sterilization medium (such as high-temperature steam) into the pressure-resi...

Embodiment 2

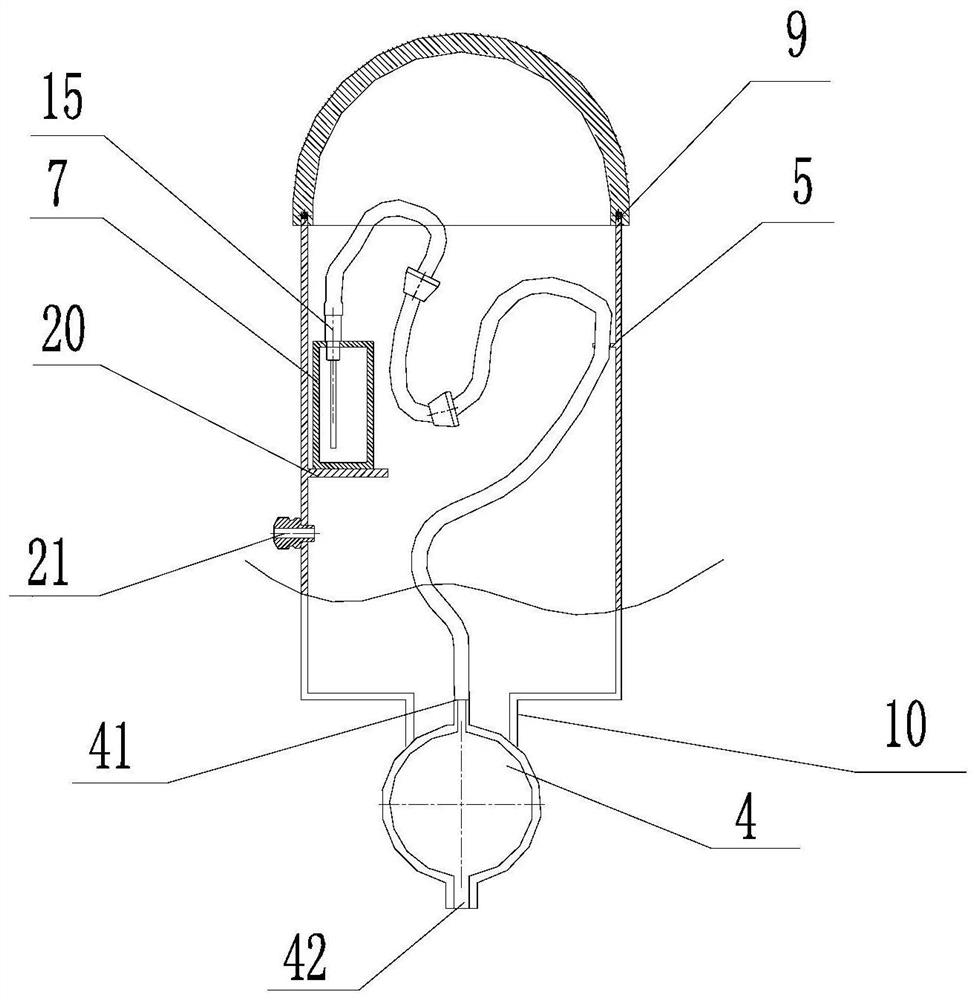

[0059] Such as Figure 3 to Figure 5As shown, the online sterilization device for filling pipelines of the present invention is used to implement the above-mentioned online sterilization method for filling pipelines. The point is: the upper parts of the two inner walls along the length direction of the cavity 1 are respectively provided with a hose fixing frame 5 and a needle filling sealing box 7; At least one needle filling fixing hole 61 is provided on the top of the box 7 . The needle irrigation sealing box 7 is fixed in the cavity 1 through the support plate 20; the irrigation needle 15 of the pipeline assembly is sealed in the needle irrigation sealing box 7 through the needle irrigation fixing hole 61; the outer wall of the cavity 1 is provided with an inflatable interface 21 .

[0060] It should be noted that, in this embodiment, the hose fixing frame 5 and the needle filling sealing box 7 are arranged parallel to each other, that is, the hose fixing frame 5 and the ...

Embodiment 3

[0064] Such as Figure 6 and Figure 7 As shown, the online sterilization device for filling pipelines of the present invention is used to implement the above-mentioned online sterilization method for filling pipelines. The point is: the top of the cavity 1 is provided with a through boss 10 extending outward, and the bottom of the cavity 1 is a sealed structure; the boss 10 is detachably sealed with the liquid distributor 4 through fasteners.

[0065] In this embodiment, by setting the cavity body 1 as a structure with one end sealed and the other end open, the overall sealing performance of the pressure-resistant airtight chamber can be further improved, and the production cost of the pressure-resistant airtight chamber can also be reduced.

[0066] It should be noted that, in the filling system, the liquid distributor 4 and the cavity 1 can be respectively arranged at different positions of the filling equipment 8 according to actual work requirements. Such as Figure 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com