Method for producing erucamid erucyl amide through circulating reactor

A loop reactor, erucamide technology, which is applied in the preparation of carboxylic acid amides, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems affecting the production cost and product quality of erucamide, and uneven mixing of amidation reaction phases. , product output and yield reduction and other issues, to achieve the effect of enhancing equipment operation flexibility, improving mass transfer and reaction efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

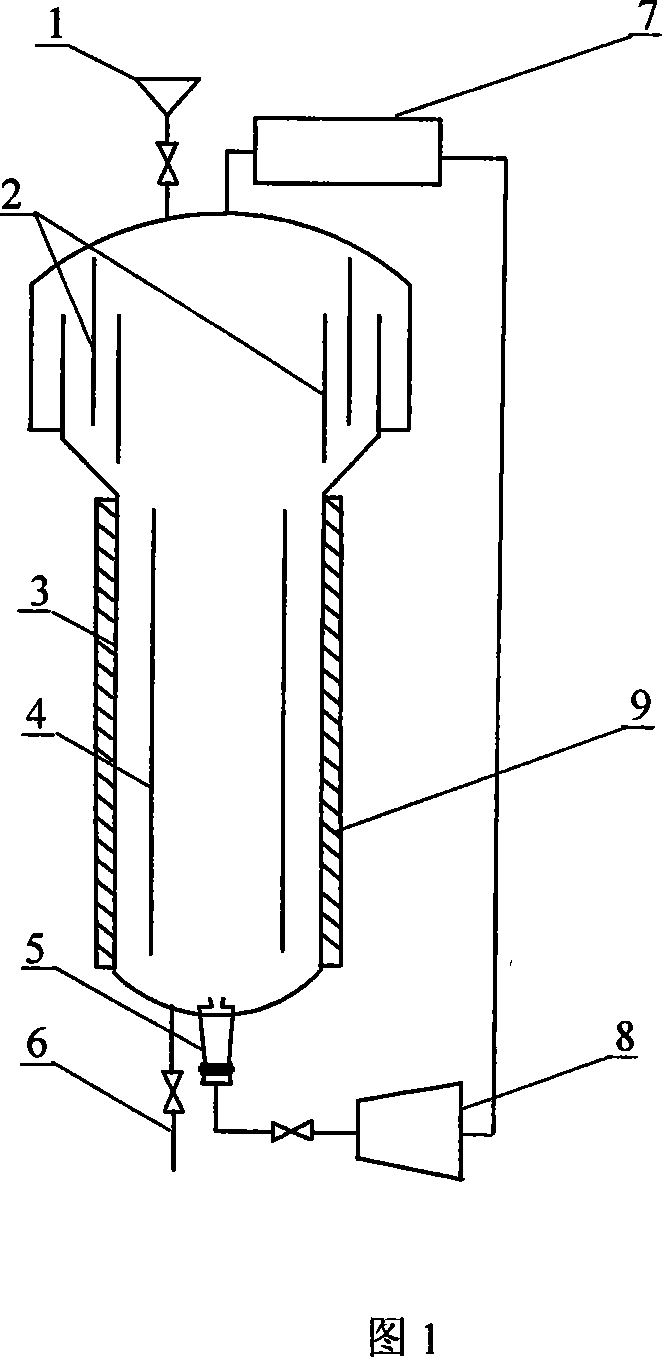

[0018] A method for producing erucamide with a loop reactor, comprising the steps of: reacting with erucic acid for ammonia addition under the catalysis of activated carbon with immobilized titanium tetrachloride on the catalyst, the production device includes a loop reactor, and the loop The top of the reactor is connected to the inlet of the drier 7 through a pipeline, and the outlet of the drier is connected to the inlet of the ammonia compressor 8, and the outlet of the ammonia compressor is connected to the cavitation chamber arranged at the bottom of the loop reactor. The nozzle 5 is connected, and the loop reactor includes an outer cylinder 3 with an expanded part on its upper part, and the guide cylinder 4 is arranged at the middle and lower part of the outer cylinder, and the height-to-diameter ratio of the guide cylinder is 3:1. The nozzle is arranged at the concentric position between the bottom of the outer cylinder and the guide cylinder, and a vapor-liquid-solid t...

Embodiment 2

[0020] The total height of the loop reactor is 1m, the diameter of the upper extension of the outer cylinder is 0.4m, the diameter of the middle and lower part of the outer cylinder is 0.2m, the diameter of the diversion cylinder is 0.15m, the height of the diversion cylinder is 0.5m, and the effective volume of the reactor is 30L A loop reactor for the production of erucamide.

[0021] Mix 0.21kg of activated carbon loaded with immobilized tetraisopropoxytitanium and 15kg of erucic acid, and add it into the loop reactor through the feed port. The ammonia gas passes through the ammonia compressor and the cavitation nozzle at a linear speed of 20m / s. Enter the above-mentioned loop reactor. Slowly heat the loop reactor to maintain the temperature in the loop reactor at 180°C. At this time, the materials in the loop reactor are vigorously mixed and moved upward in the guide tube under the jetting action of the cavitation nozzle, and are distributed in the entire loop reactor. A ...

Embodiment 3

[0024] The total height of the loop reactor is 1m, the diameter of the upper extension of the outer cylinder is 0.4m, the diameter of the middle and lower part of the outer cylinder is 0.2m, the diameter of the diversion cylinder is 0.15m, the height of the diversion cylinder is 0.5m, and the effective volume of the reactor is 30L A loop reactor for the production of erucamide.

[0025] 0.13 kg of activated carbon loaded with immobilized tetra-n-propyl zirconate and 13 kg of erucic acid were mixed, and added to the loop reactor through the feed port, and the ammonia gas passed through the ammonia compressor and the cavitation nozzle at a linear speed of 20 m / s. Enter the above-mentioned loop reactor, slowly heat the loop reactor, and maintain the temperature in the loop reactor at 165°C. At this time, the materials in the loop reactor are vigorously mixed and moved upward in the guide tube under the action of the injection of the cavitation nozzle, and A loop is formed in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap