Assembling method for seal assembly in magnetic liquid seal device

A technology of sealing components and sealing devices, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as difficult cleaning, affecting the working performance of sealing components, and difficult cleaning of sealing components, so as to achieve convenient cleaning and shorten cleaning time, easy assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in conjunction with accompanying drawing:

[0015] A method for assembling a sealing component in a magnetic liquid sealing device, the steps of the method:

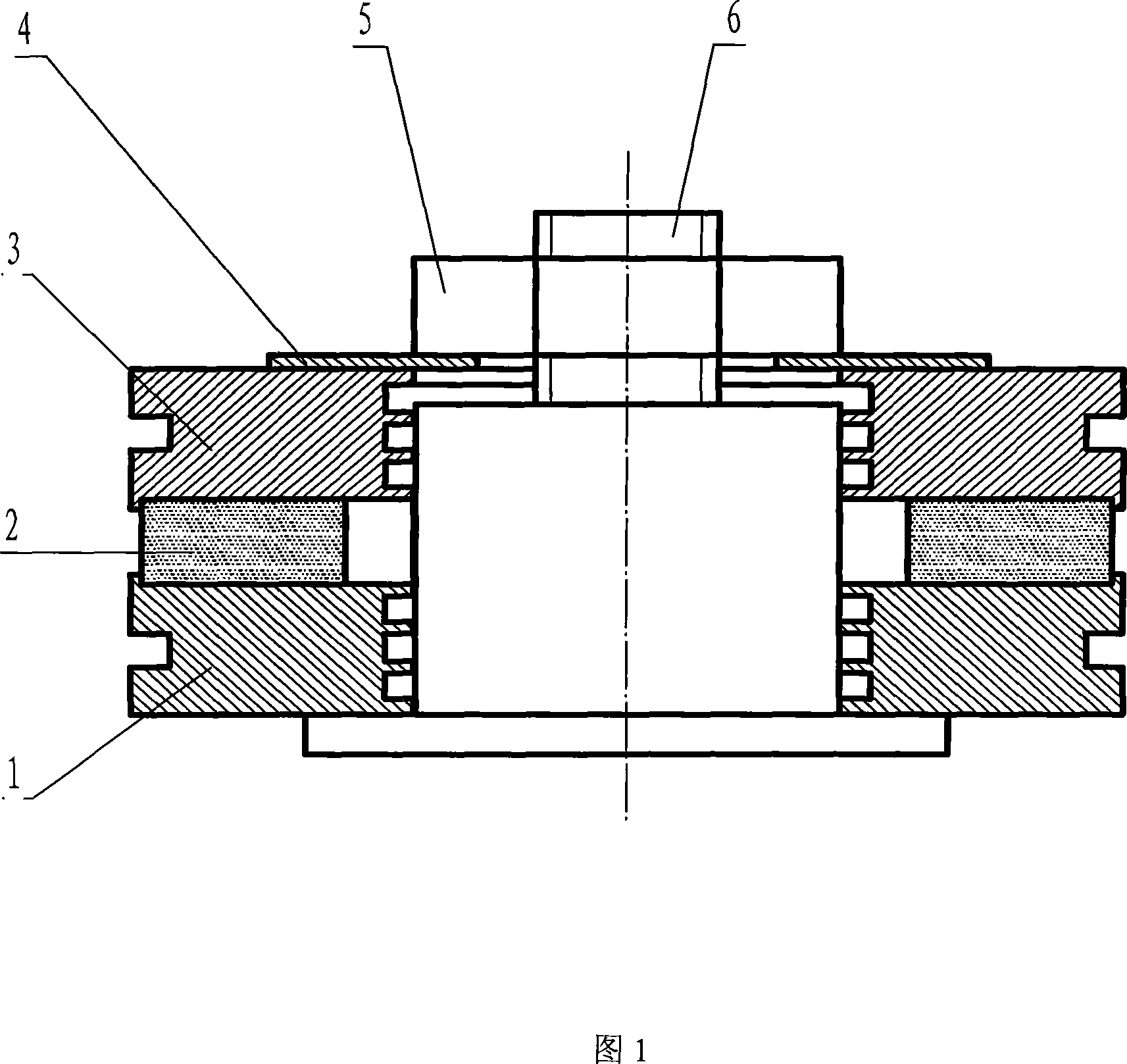

[0016] Step 1, apply glue on the joint surface of the lower pole piece 1, NdFeB ring 2, and upper pole piece 3 in sequence, and bond them together to form a sealing assembly, and lock the sealing assembly in the process with gasket 4 and nut 5 on mandrel 6;

[0017] Step 2: Grinding the outer circles of the lower pole piece 1 and the upper pole piece 3 of the seal assembly formed in step 1 on a grinding machine, so that the matching gap between the outer circle and the inner hole of the housing of the magnetic liquid sealing device is 0.02mm to Between 0.03mm.

[0018] Step 3, after grinding, take out the process mandrel 6, gasket 4 and nut 5, and use acetone or gasoline to clean the sealing assembly formed by the lower pole piece 1, the upper pole piece 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com