Measuring system and its measuring method for large field object micro surface three dimension topography

A technology of three-dimensional shape and measurement system, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of measuring the surface shape of non-transparent objects, etc., so that the aberration will not deteriorate, the accuracy will be increased, and the measurement accuracy will be high. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The measurement system and method for measuring the three-dimensional topography of the microscopic surface of objects with a large field of view according to the present invention will be described in detail below in conjunction with the embodiments.

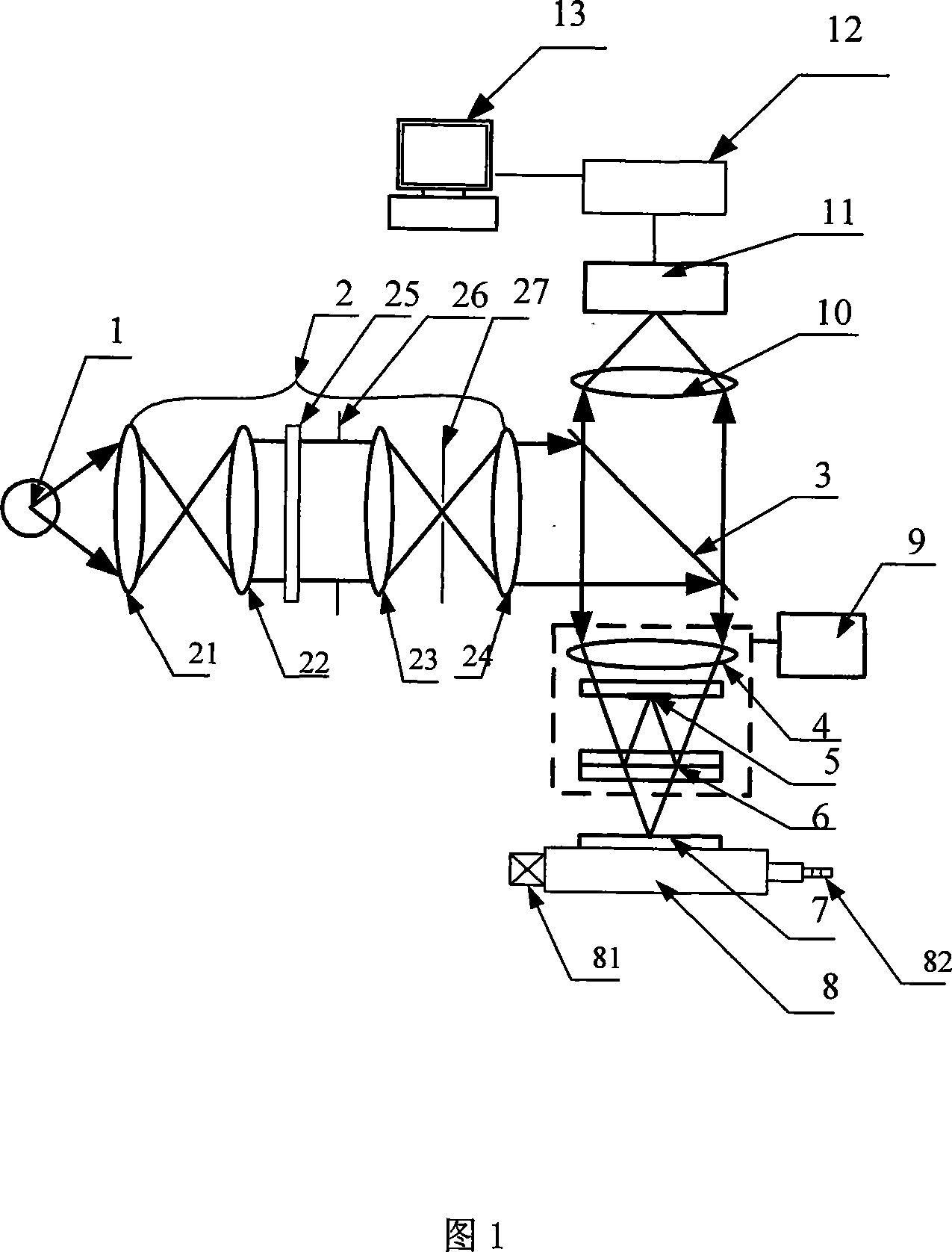

[0048] The measurement system for the three-dimensional topography of the microscopic surface of a large field of view object of the present invention includes a light source 1, and is also provided with a concentrating system 2 for receiving the light source 1. The concentrating system 2 includes: first concentrating mirrors 21 arranged in sequence , the second condenser lens 22, an optical filter 25, an aperture stop 26, the third condenser lens 23, a field diaphragm 27, and a fourth condenser lens 24; the output light side of the condenser system 2 is provided with a first light splitter Mirror 3; a microscopic objective lens 4, a reference surface 5, a second beam splitter 6, a measured surface 7, and a precision disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com