A surface-array point-scanning spectroscopic white light interferometer

A white light interferometer and point scanning technology, applied in the field of optical instruments, can solve problems such as inability to receive reflected light, failure to achieve detection results, misjudgment of detection results, etc., to achieve good energy uniformity, large detection depth of field range, and stable energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

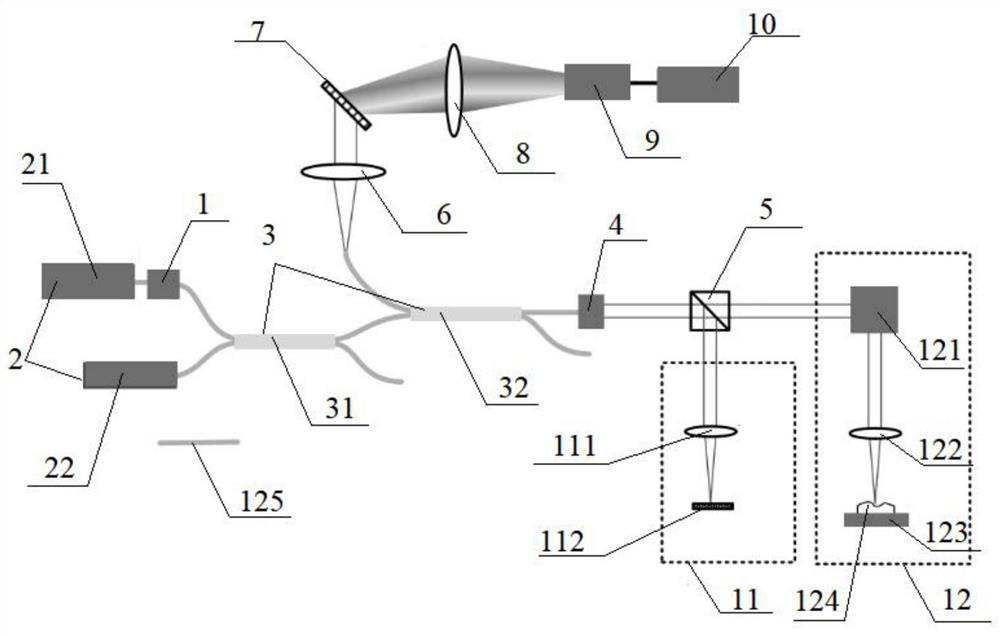

[0065] Such as Figure 1-4 As shown, the SLD light source uses a near-infrared broadband light source with a power of 25mw and a wavelength of 810-870nm; the isolator uses an 850nm broadband isolator; the coupler is an X-type single-mode fiber coupler, the numerical aperture of the fiber is 0.13, the core diameter is 5um, and the splitting ratio is 50 : 50; collimator adopts diffractive polar achromatic lens, focal length is 18.45mm; beam splitting prism splitting ratio is 50:50; third lens is achromatic lens with focal length 50mm; mirror is coated with near-infrared high reflection film, reflectivity >99.5% ;The XY scanning galvanometer has an effective incident spot diameter of 7mm and a maximum scanning angle of 5 degrees; the grating is a 1800lp transmission grating with a blaze angle of 49.2 degrees@840nm; the first lens and the second lens use the same achromatic telecentric lens, and the field of view angle is 10 degrees , the focal length is 83.9mm; the pixel size of ...

Embodiment 2

[0068] Such as Figure 10 As shown, compared with Embodiment 1, the remaining modules remain unchanged, and only the fourth lens is replaced to achieve different scanning ranges and different depths of field. The fourth lens has a field of view of 28 degrees, a focal length of 70mm, and an entrance pupil diameter of 5mm. The scanning field of view is 24.4*24.4mm, and the depth of field is 0.67mm.

[0069] Such as Figure 11 as shown, Figure 11 It is the MTF curve of the fourth lens of this embodiment, which basically reaches the diffraction limit level and has high resolution.

Embodiment 3

[0071] Such as Figure 12 As shown, compared with Embodiment 1, the remaining modules remain unchanged, and the fourth lens is replaced to achieve different scanning ranges and different depths of field. The fourth lens has a field of view of 28 degrees, a focal length of 100mm, and an entrance pupil diameter of 5mm. The scanning field of view is 34.9*34.9mm, and the depth of field is 1.36mm.

[0072] Such as Figure 13 as shown, Figure 13 It is the MTF curve of the fourth lens in Example 3, which basically reaches the diffraction limit level and has high resolution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com