Comprehensive detection control device design method for electric connector

A technology of electrical connectors and control devices, which is applied in the direction of measuring devices, instruments, and measuring electronics, can solve the problems of low efficiency of electrical connector testing, low testing process safety, and high testing voltage, so as to eliminate the phenomenon of missed testing, The effect of improving test efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

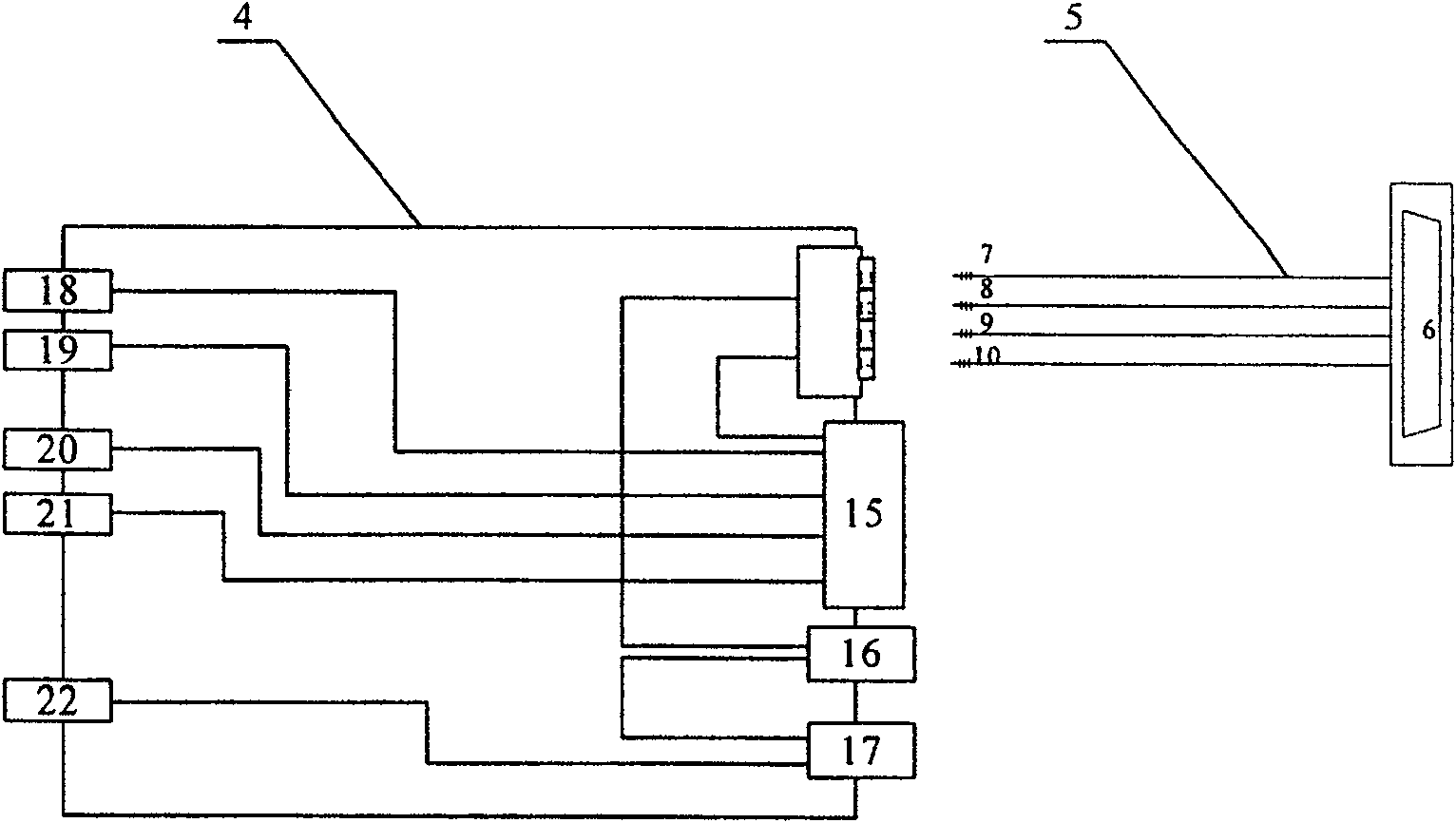

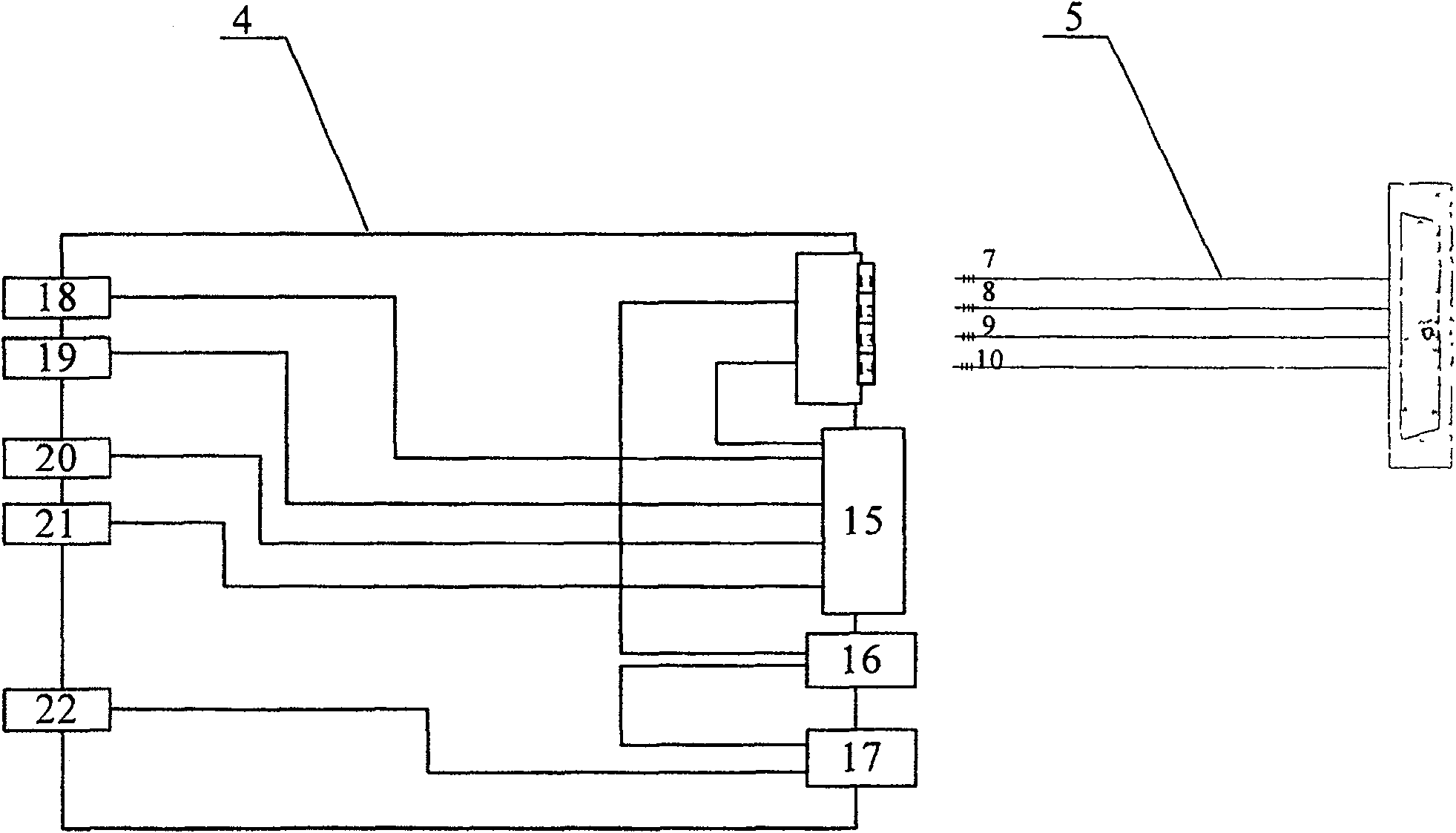

[0026] Take the tested object as an example of a nine-core two-row pin-type rectangular electrical connector with a tail wire insulated shell.

[0027] The special test cable 5 has two interfaces, one interface is a nine-core socket electrical connector 6 that can be fully mated with the object under test, and the sequence of the sockets is marked as 6a, 6b, 6c, 6d, 6e, 6f , 6g, 6h, 6i, group electrical connector jacks according to the technical scheme: the first group includes jacks 6a, 6d, 6g, the second group includes 6b, 6e, 6h, and the third group includes 6c, 6f, 6I, Since the shell of the electrical connector under test is an insulator, the fourth group is not needed, and the tail wires of the three groups of jacks are crimped and connected with three plugs that can be plugged into the host.

[0028] Welding of the double-pole three-layer six-position switch, the first group of test point sockets 11 are welded to the normally closed point 23 of the first layer of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com