Under water separate electric connector

A technology of electrical connectors and water inlet tanks, which is applied in the direction of connection and connection device parts, circuits, etc., can solve the problems of only being able to go underwater, low efficiency, and cumbersome oil storage operations, and achieve convenient and fast connection and cumbersome operation , the effect of separating simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

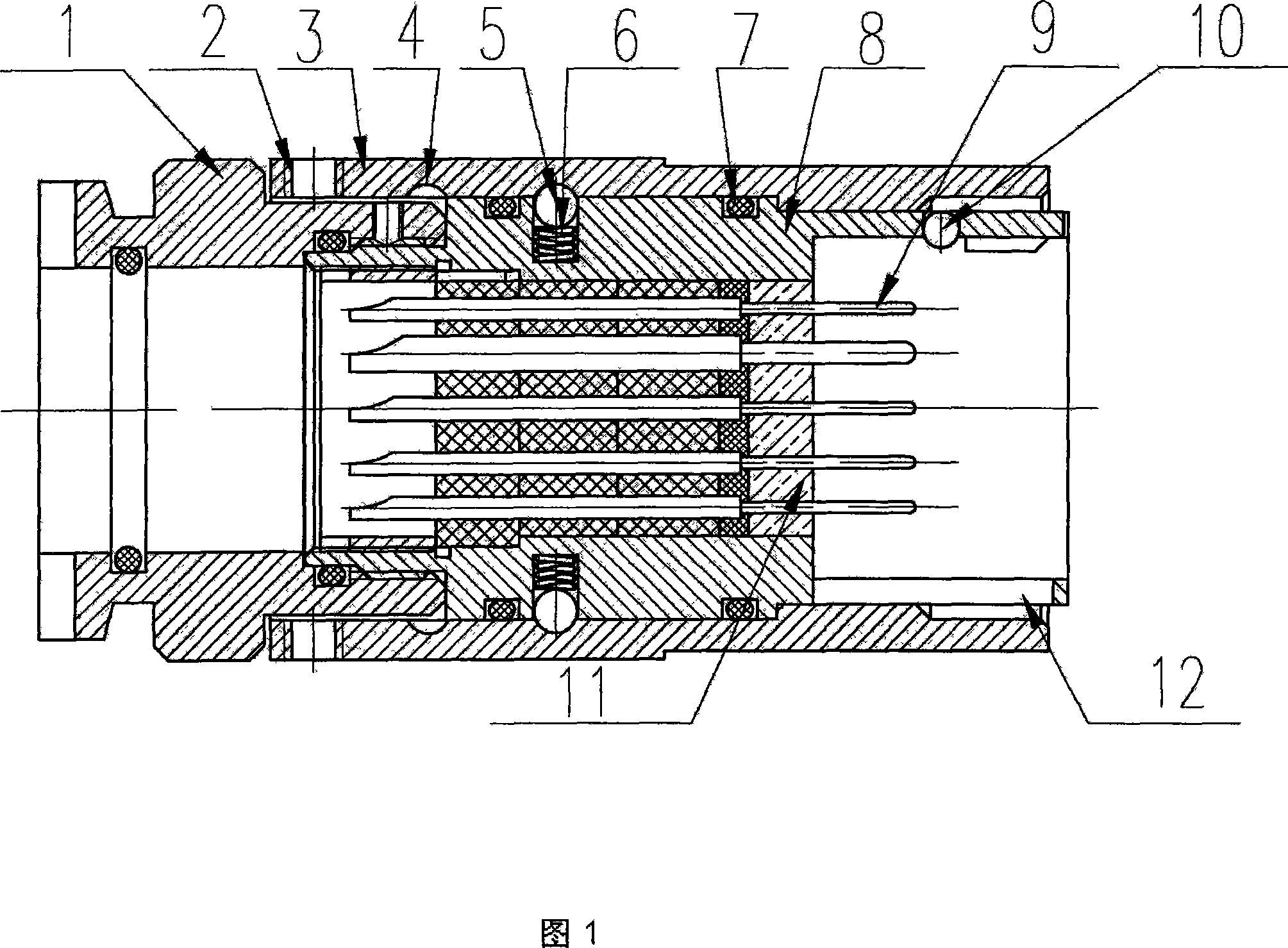

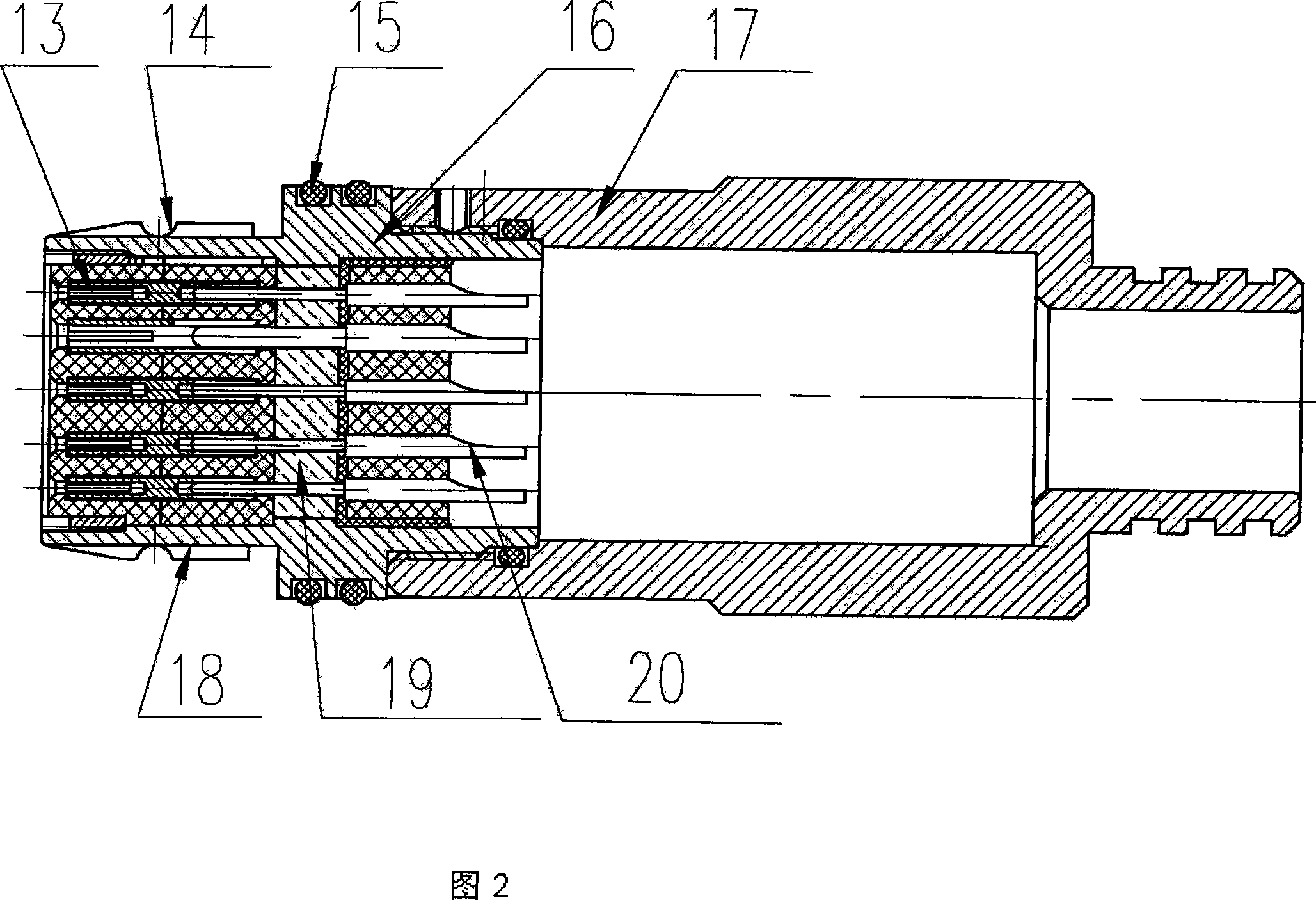

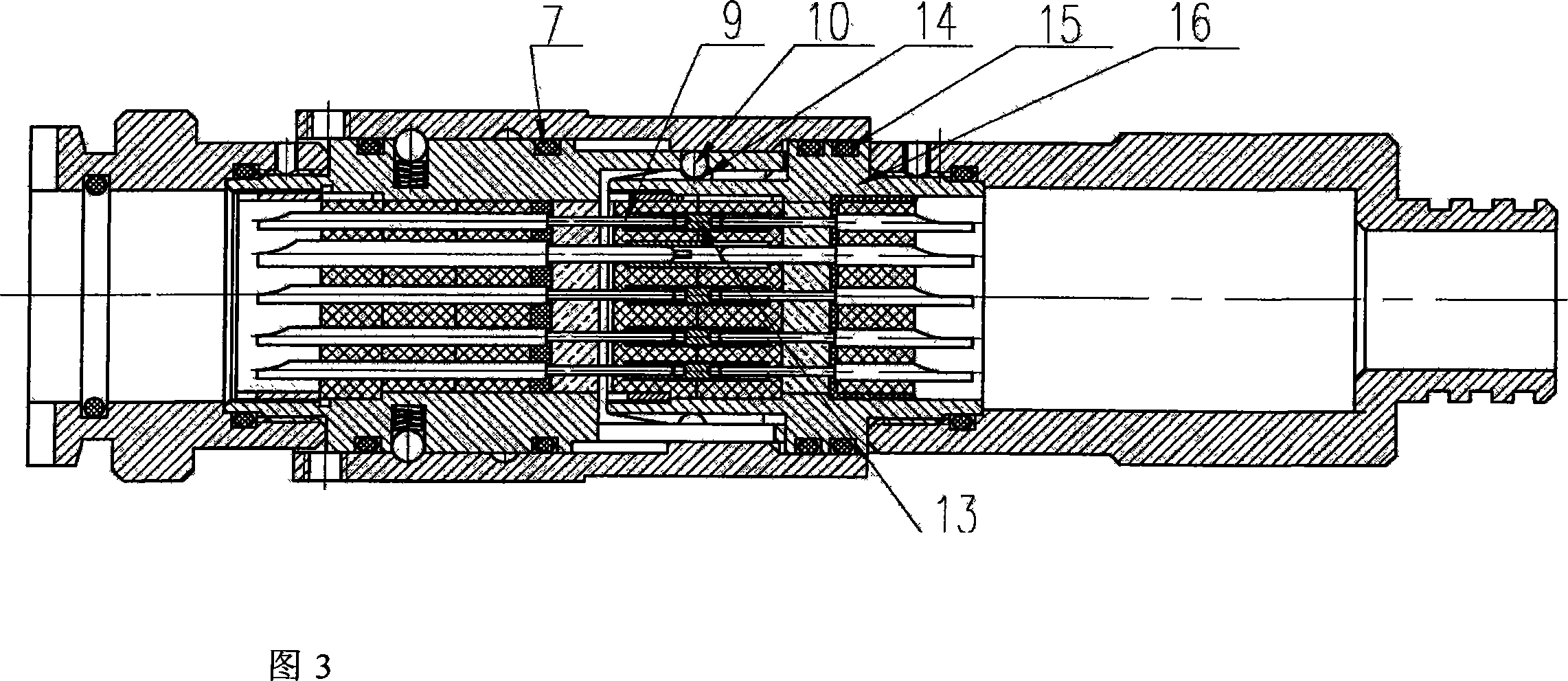

[0025] As shown in Figure 1, an unlocking sleeve 3 is provided on the underwater separation socket, and an installation hole 2 on the unlocking sleeve is connected with a release mechanism provided by the user, and the movement of the release mechanism can drive the unlocking sleeve 3 to move. The unlocking sleeve 3 is provided with a step matched with the socket housing, and the unlocking sleeve can pull the socket housing 8 to move through the steps to realize the complete separation of the head seat. The socket housing 8 is provided with a first O-ring seal 7, and the anti-unlock sleeve 3 retreats with the steel ball 5 and the spring 6. It is installed between the two first O-ring seals 7. The spring 6 will not contact seawater, and the unlocking sleeve 3 is provided with a circular groove 4, and the spring 6 bears on the steel ball 5 and is stuck in the circular groove 4, which can prevent the unlocking sleeve 3 from retreating. The head seat locking steel ball 10 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com