Heat radiation fin

A technology of heat dissipation fins and heat sinks, applied in cooling/ventilation/heating transformation, instrument cooling, instruments, etc., can solve the problems of bending and deformation of heat sink 20, affecting heat dissipation effect, impracticality, etc., and achieves stable structure and easy disassembly Easy Action, High Quality Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

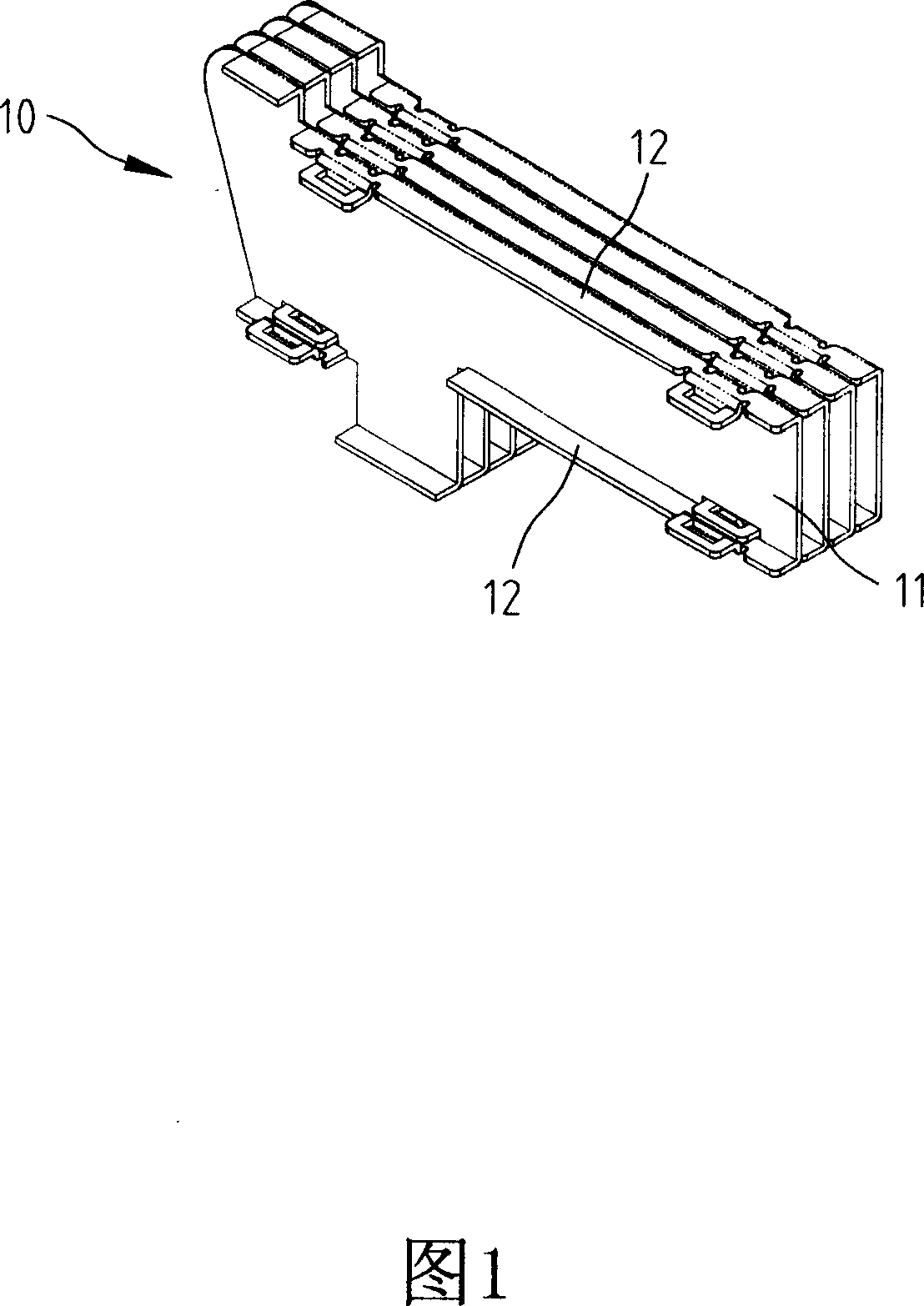

[0025] Referring to Fig. 1, the cooling fins of the present invention are formed by combining multiple cooling fins 10; wherein:

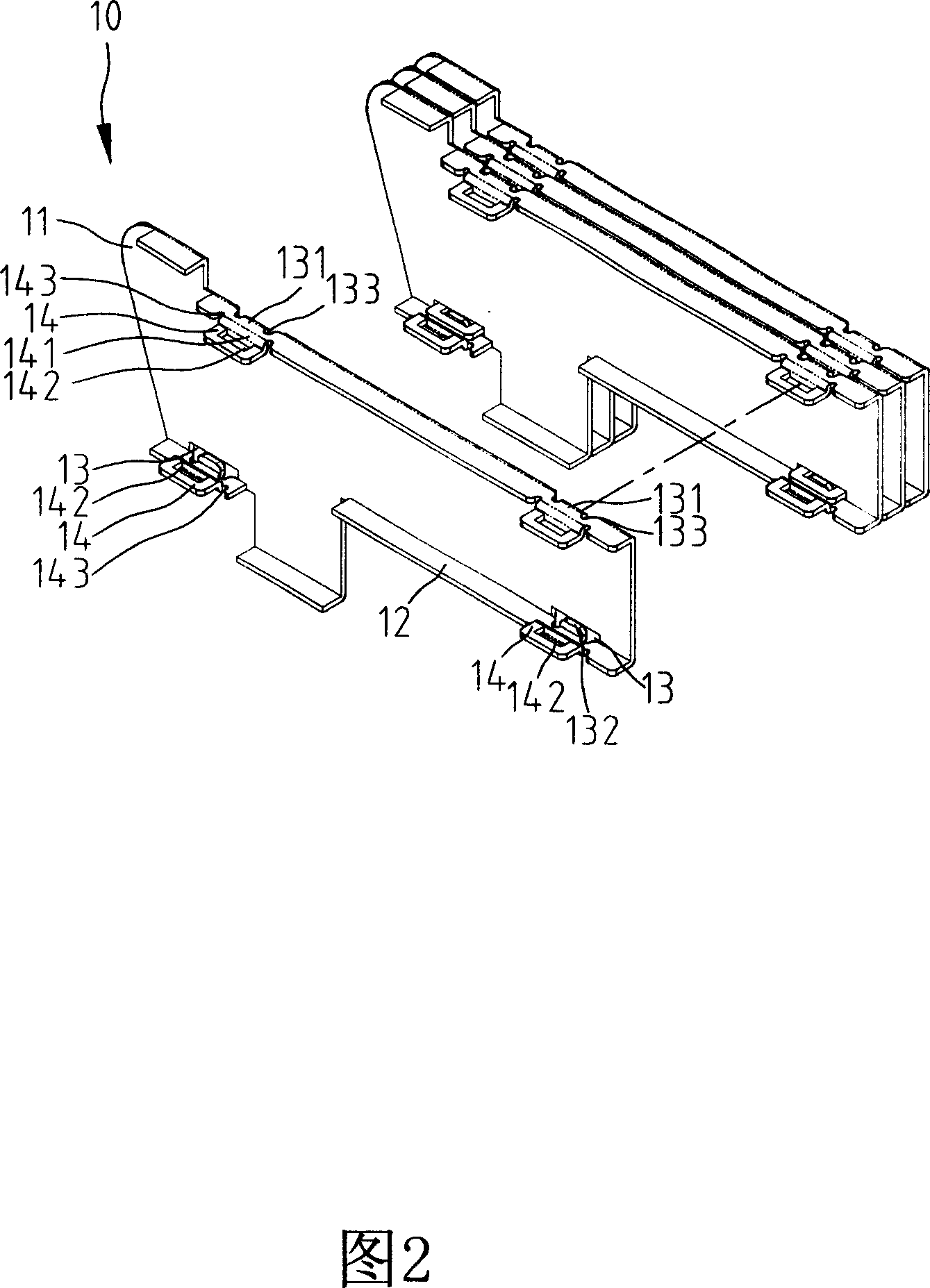

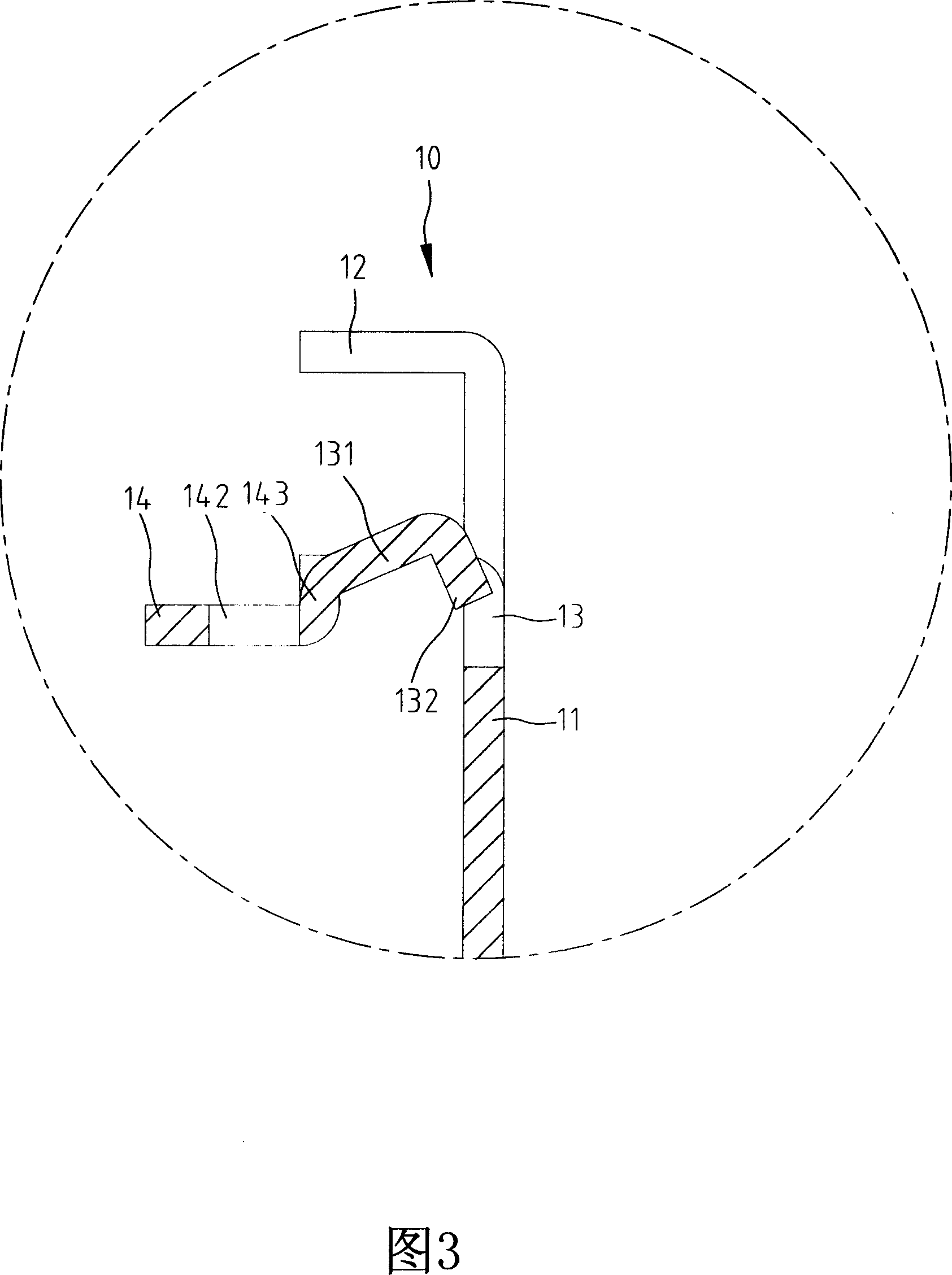

[0026] Referring to FIG. 2 and FIG. 3 , this embodiment illustrates a situation in which multiple heat sinks 10 can be disassembled and assembled with each other. The number of assembled fins in actual use is not a feature of this case and is not limited by this embodiment. The heat sink 10 has a bottom wall 11, and a plurality of vertically extending side walls 12 are respectively formed on the upper and lower sides of the bottom wall 11, and several engaging grooves 13 are formed at the turning points of the bottom wall 11 and the side walls 12. , and the sidewalls 12 are protrudingly provided with several clips 14 snapped into the clip slots 13 .

[0027] An inserting portion 131 extending from the side wall 12 is provided in the snap-in slot 13 , and an inserting end 132 is formed at the end of the inserting portion 131 with a 90-degree turn. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com