Producing technology for slice type ice cream

A production process and ice cream technology, applied in the fields of frozen desserts, food science, and applications, can solve the problems of unsatisfactory taste of ice cream, single and rigid structure, and inability to intuitively and accurately judge by consumers, so as to improve the appearance and structure, and improve the The effect of market competitiveness and novel appearance and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

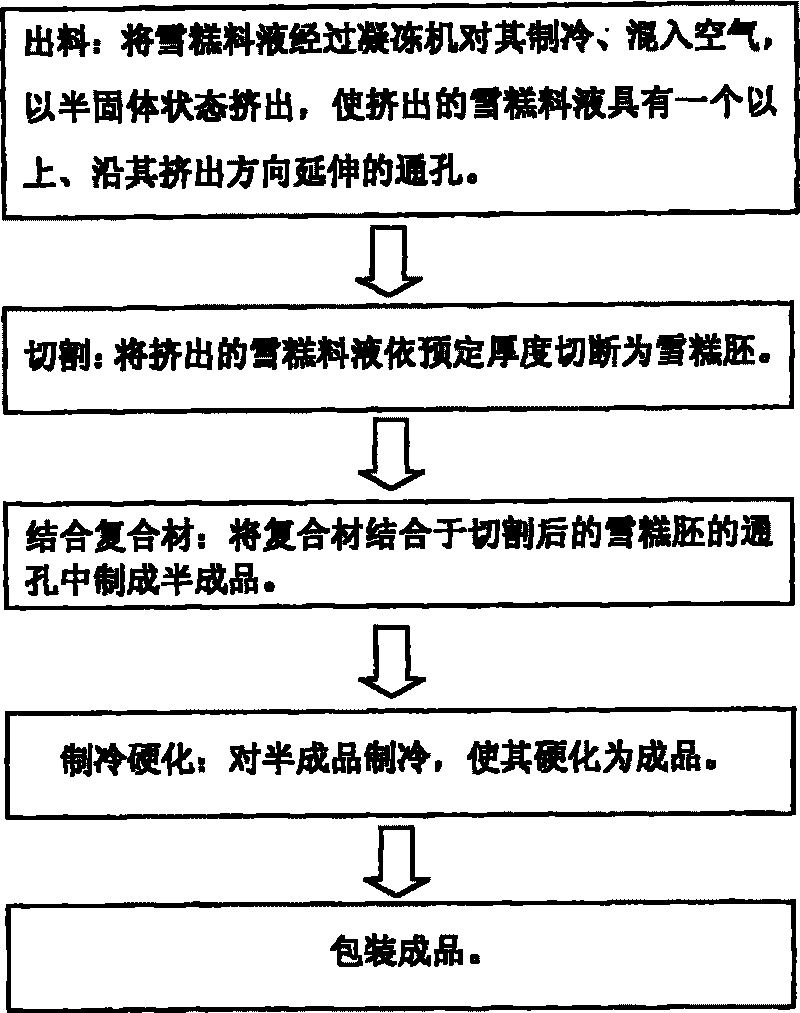

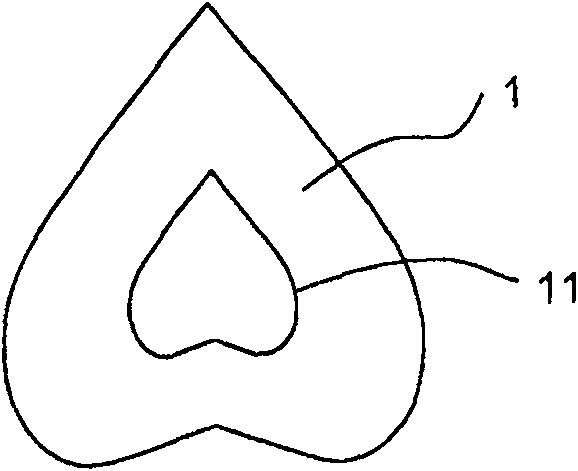

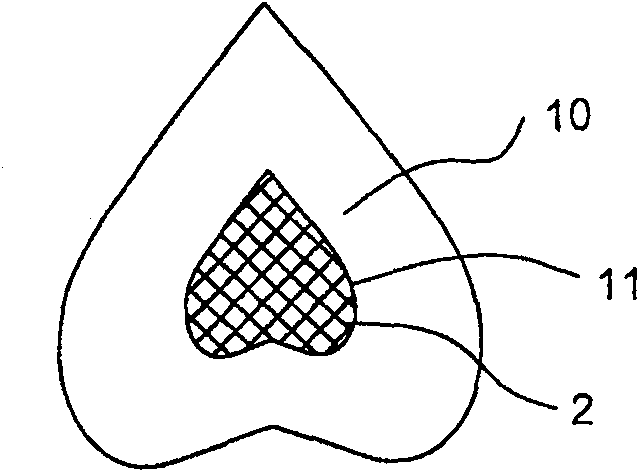

[0035] Such as figure 1 As shown, the present invention provides a production process of sliced ice cream, which is now described by taking the production of ice cream products whose outer contour and chocolate block composite materials are heart-shaped as an example, including the following steps:

[0036] A) discharge: the ice cream material liquid is refrigerated by a freezer, mixed with air to expand, and extruded in a semi-solid state, so that the extruded ice cream material liquid has more than one through hole extending along its extrusion direction; preferably , the discharge temperature is controlled within the range of -1°C to -7°C, the optimum discharge temperature is about -4°C, and the expansion rate is 20% to 200%. Wherein, the shape and size of the outlet are consistent with the shape and size of the finished ice cream product, and the section of the mouth is two heart-shaped ring-shaped structures. The shapes are consistent, they are all heart-shaped, such a...

Embodiment 2

[0047] Such as Figure 8-14 As shown, the principle and effect of this embodiment are exactly the same as those of Embodiment 1, and will not be repeated. One of the differences is: between step B) and step C), step F) is also included to insert chopsticks, such as Figure 9 As shown, a chopstick body 3 is inserted, and since the ice cream 10 includes the chopstick body 3, the inner packaging of the tray box can be omitted in step E, and the direct outer packaging of the plastic bag is adopted. The second difference is: in step C) of this embodiment, it is dedicated to pouring liquid composite materials, such as pouring liquid chocolate into the through hole 11, so that the liquid chocolate is wrapped on the outer periphery of the chopsticks body 3 and then undergoes the cooling and hardening step D) Congealed into a solid composite raw material block. Produced by this process as Figures 10-14 The various sliced ice creams shown, compared with Figure 3-7 The sliced ic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com