Slide roller sieve

A technology of sliding roller and sieve bed, which is applied in the direction of sieving, solid separation, grid, etc., which can solve the problems that the screening work cannot be carried out, it is not suitable for the screening of viscous powder and granular materials, and the order of magnitude of the mesh is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further illustrate the present invention, below in conjunction with embodiment is described in more detail.

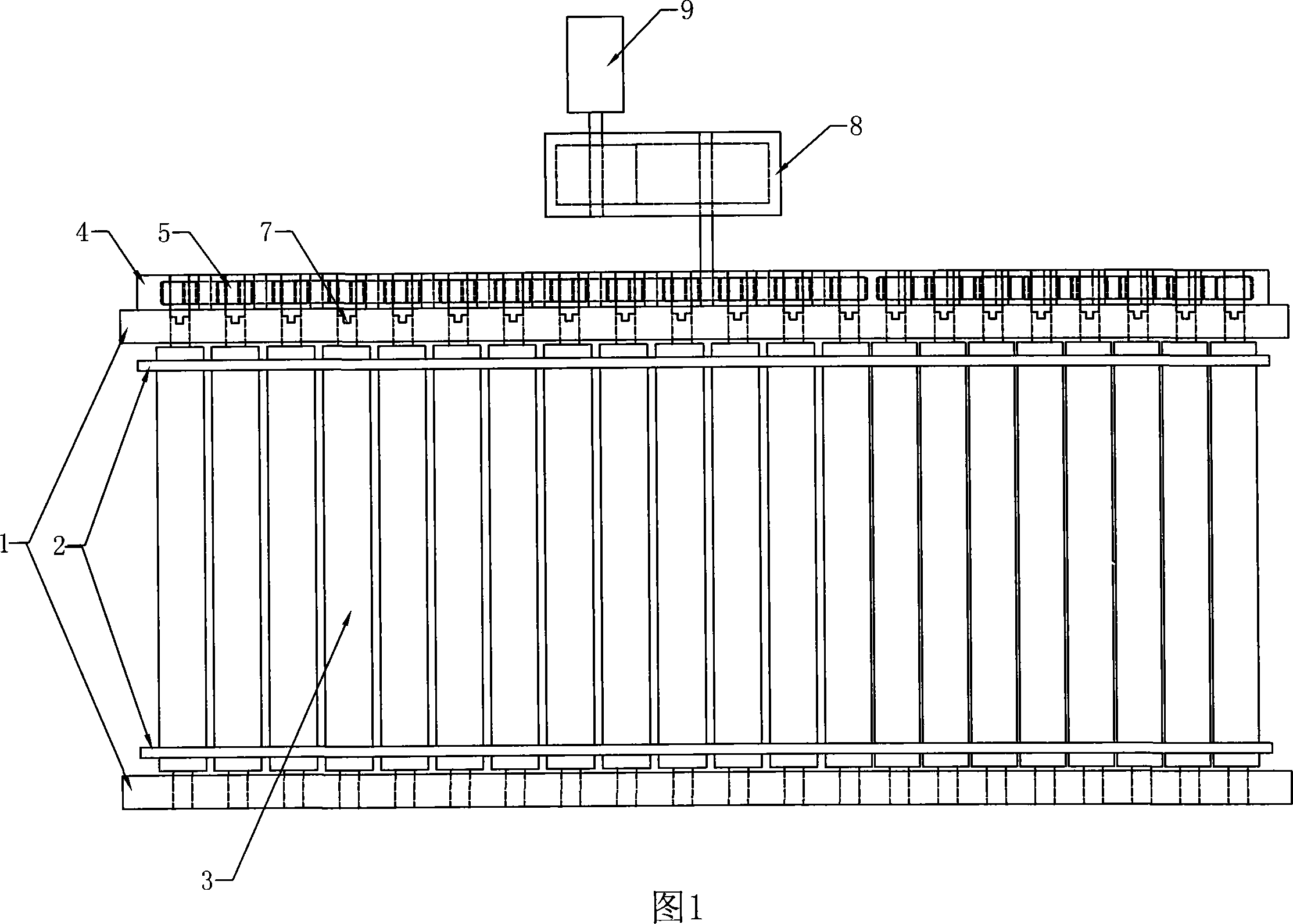

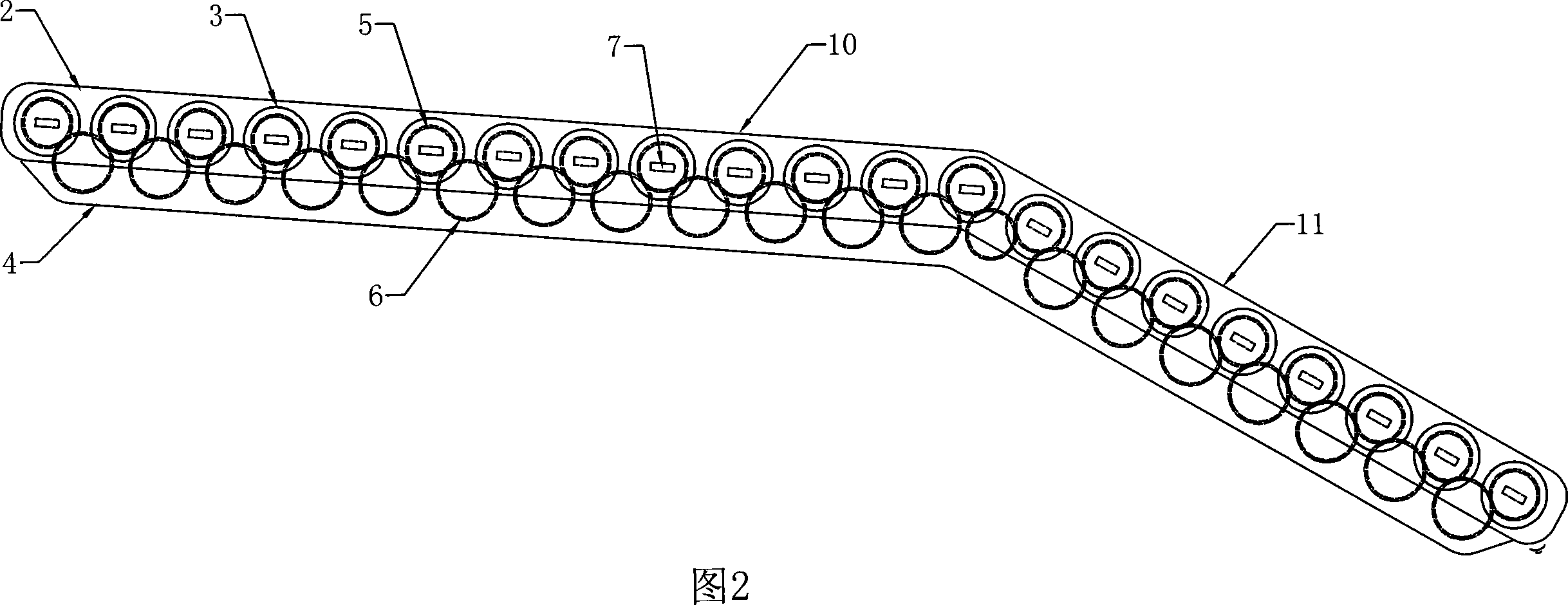

[0019] Figure 1 is a top view of the roller screen, and Figure 2 is a side view of the roller screen. Among them, between two side frames 1 supported by crossbeams, a lot of sliding rollers 3 are placed next to each other, and the side frames 1 are filled to form a sieve bed; these sliding rollers 3 both ends have shaft heads 30, 32 (see Fig. 4), placed in the bearing on the side frame 1.

[0020] Leave a gap between two adjacent slip rollers 3, and this gap is just equivalent to the mesh of screen cloth.

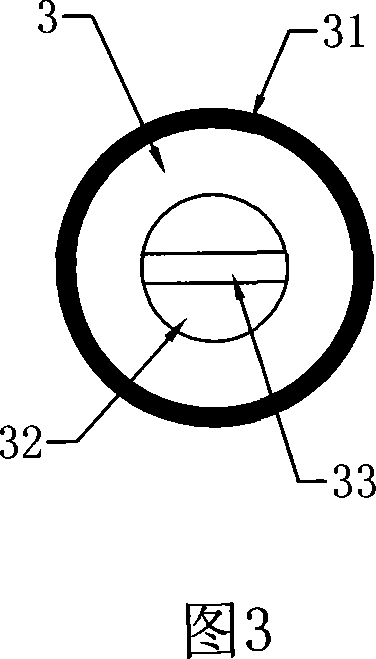

[0021] On one side of the sieve bed, next to the outside of the side frame 1, there is a gear box 4; in the gear box 4, corresponding to each slip roller 3, there is a driving gear 5, the driving gear 5 and the corresponding slip roller 3 The shaft heads 32 are connected by detachable tenons (see Fig. 3 and Fig. 4); that is to say, all the slidi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap