Middle and low speed magnetic levitation track girder

A technology of maglev track and track beam, which is applied to joists, girders, trusses and other directions, can solve the problems of high erection cost, self-heavy weight, and high concrete consumption, so as to reduce concrete consumption, erection cost and project investment. , the effect of reducing volume and self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

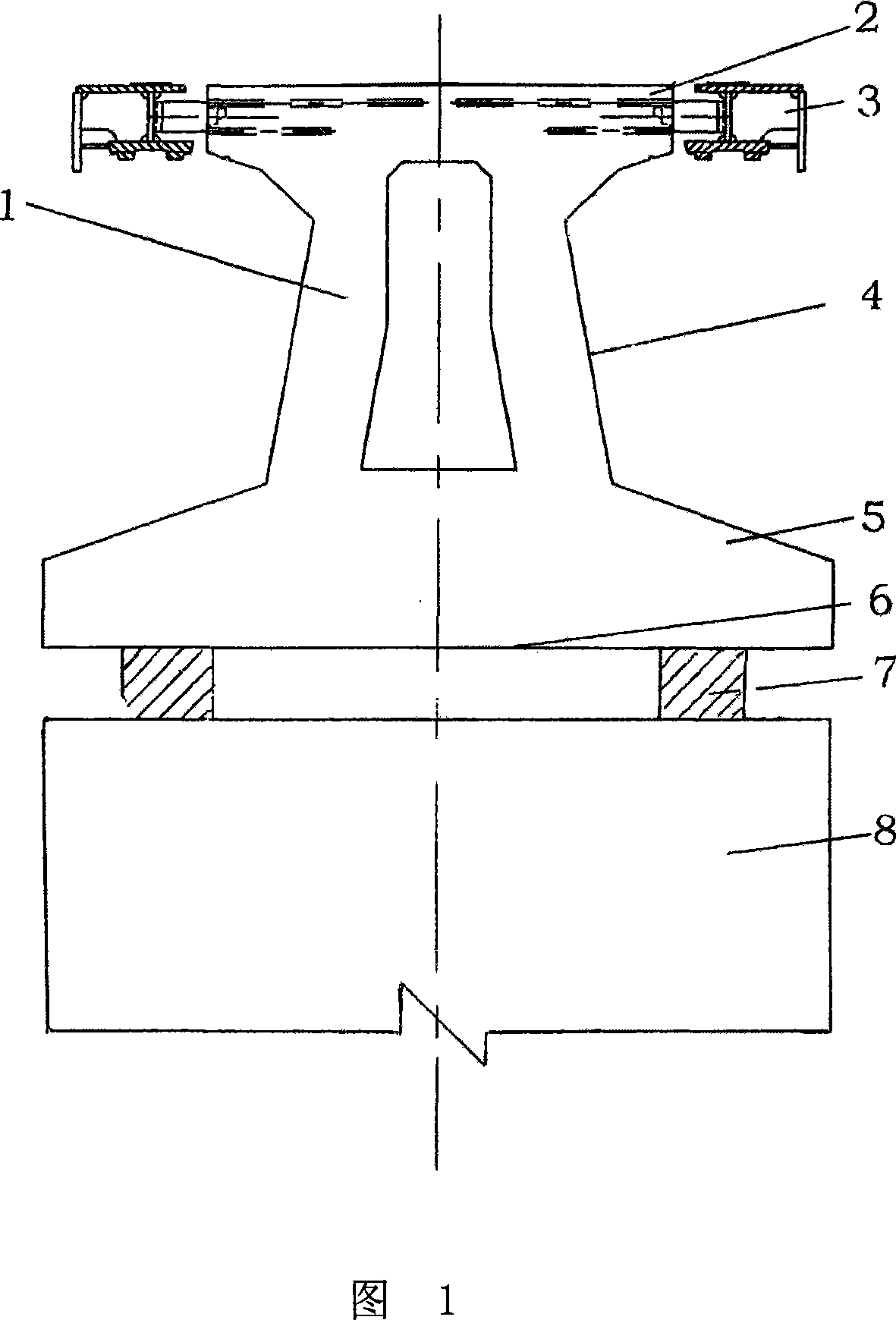

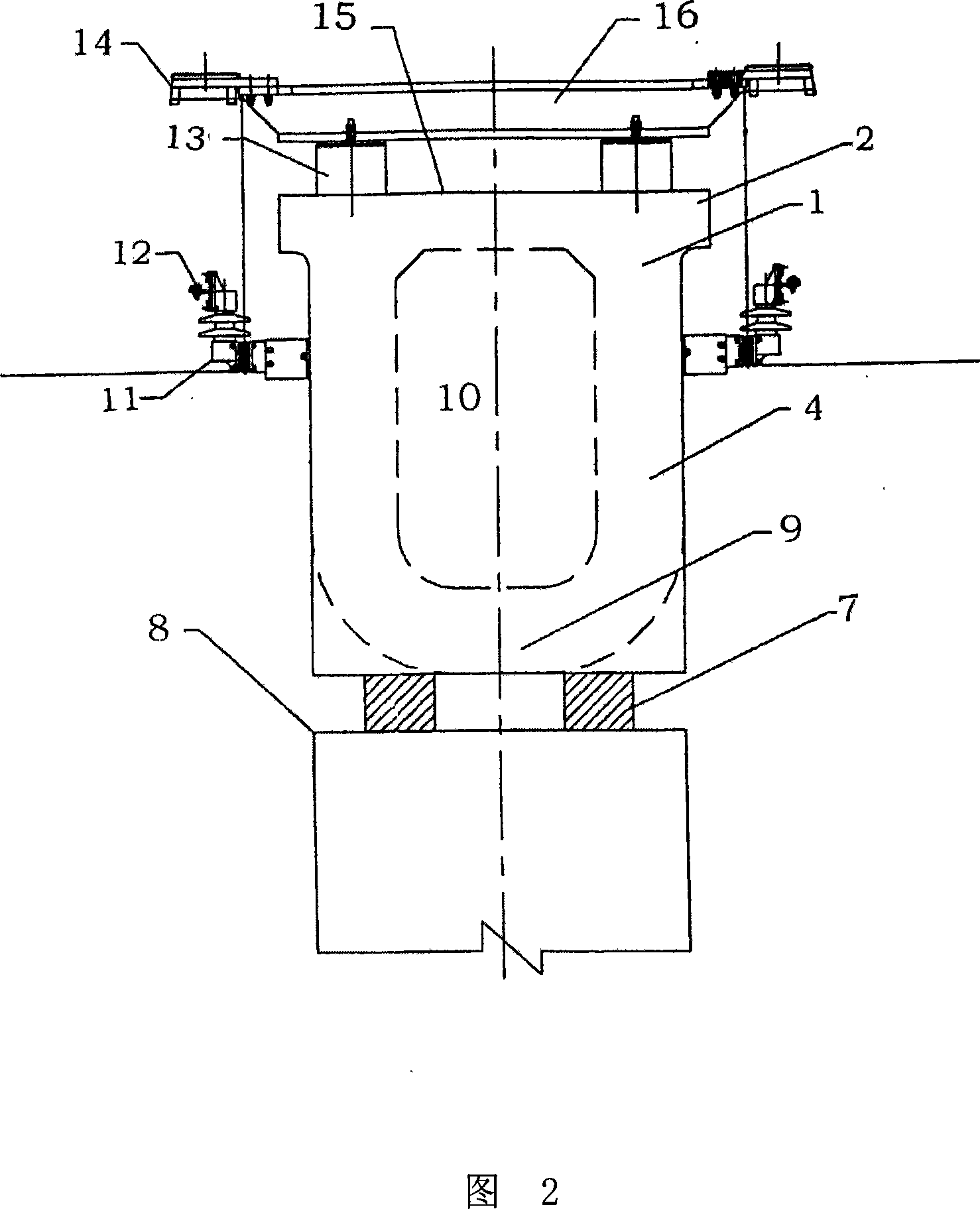

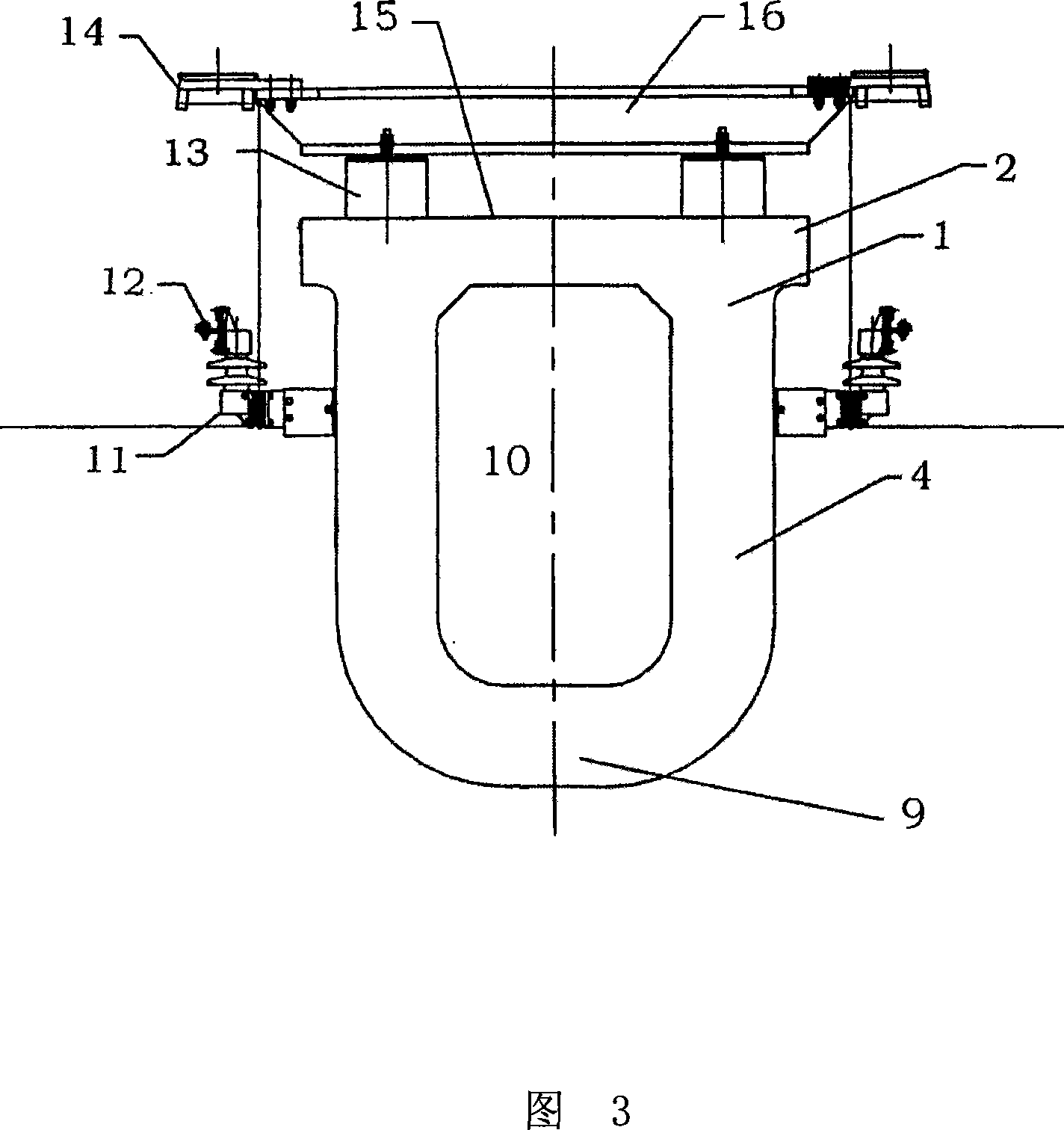

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

[0032] Fig. 2 and Fig. 3 show the cross-sectional view of the track beam of the U-shaped beam bottom involved in the present invention, Fig. 4 and Fig. 5 respectively show the track beam cross-sectional view of the rectangular and V-shaped beam bottom involved in the present invention, and Fig. 6 shows the present invention The cross-sectional view of the track beam at the fulcrum of the curved section, Figures 7 and 8 show the connection mode of the track beam and the rail row of the present invention.

[0033] As shown in the figure, the medium and low-speed maglev track beam 1 involved in the present invention includes an upper flange 2, a web 4 and a beam bottom 9. The upper flange 2 is located on the top of the track beam 1, and the beam bottom 9 is located at the bottom of the track beam 1. Bottom, the web 4 is placed between the upper flange 2 and the bottom 9 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com