Strain computer-controlled beam support and change method

A strain control, computer technology, applied in building maintenance, construction, building construction, etc., can solve the problems of consuming the energy and time of technicians, affecting the safety and durability of the structure, and danger to the structure and operators, and achieves convenient construction. The effect of rapidity, low equipment cost, and safety guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

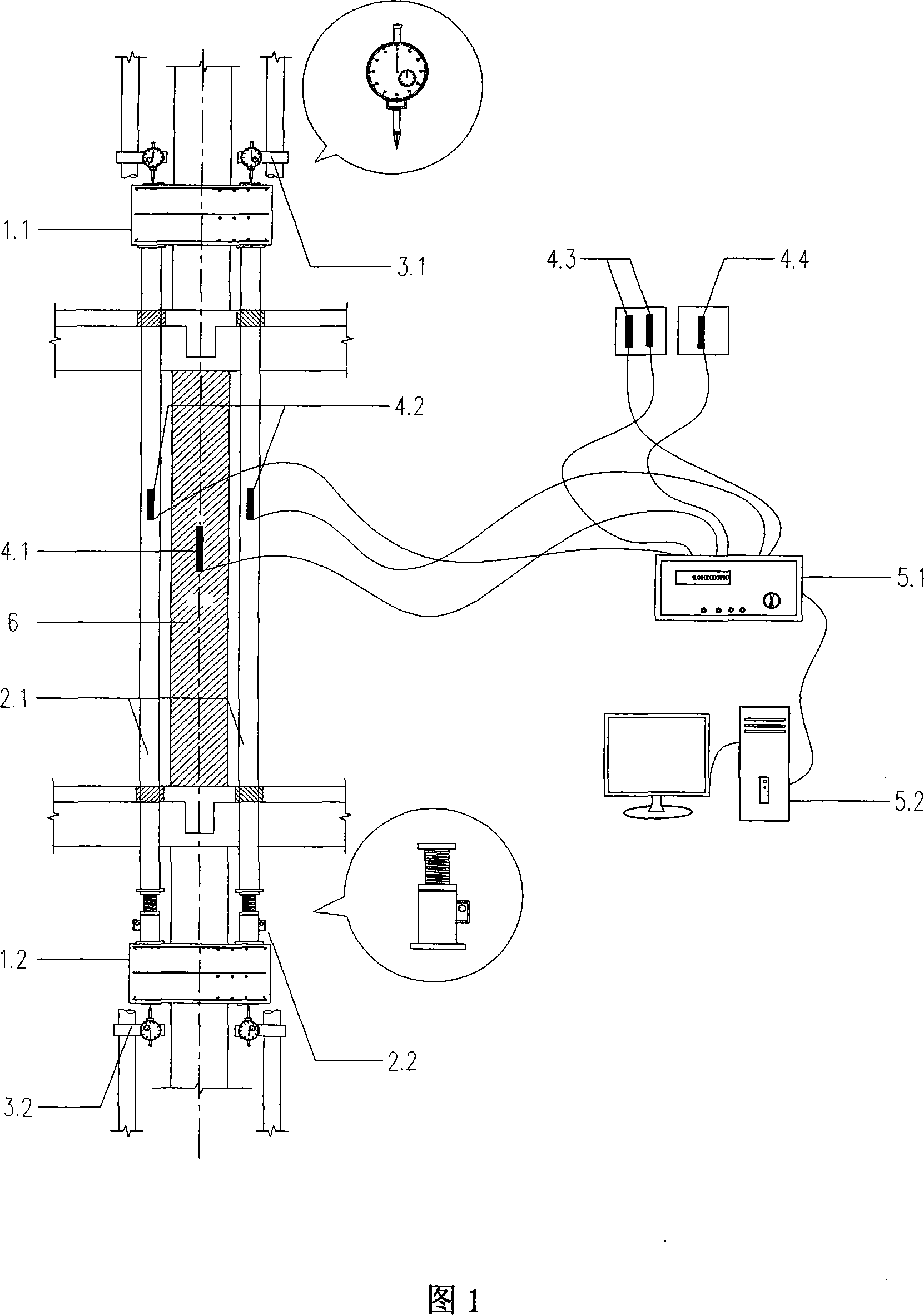

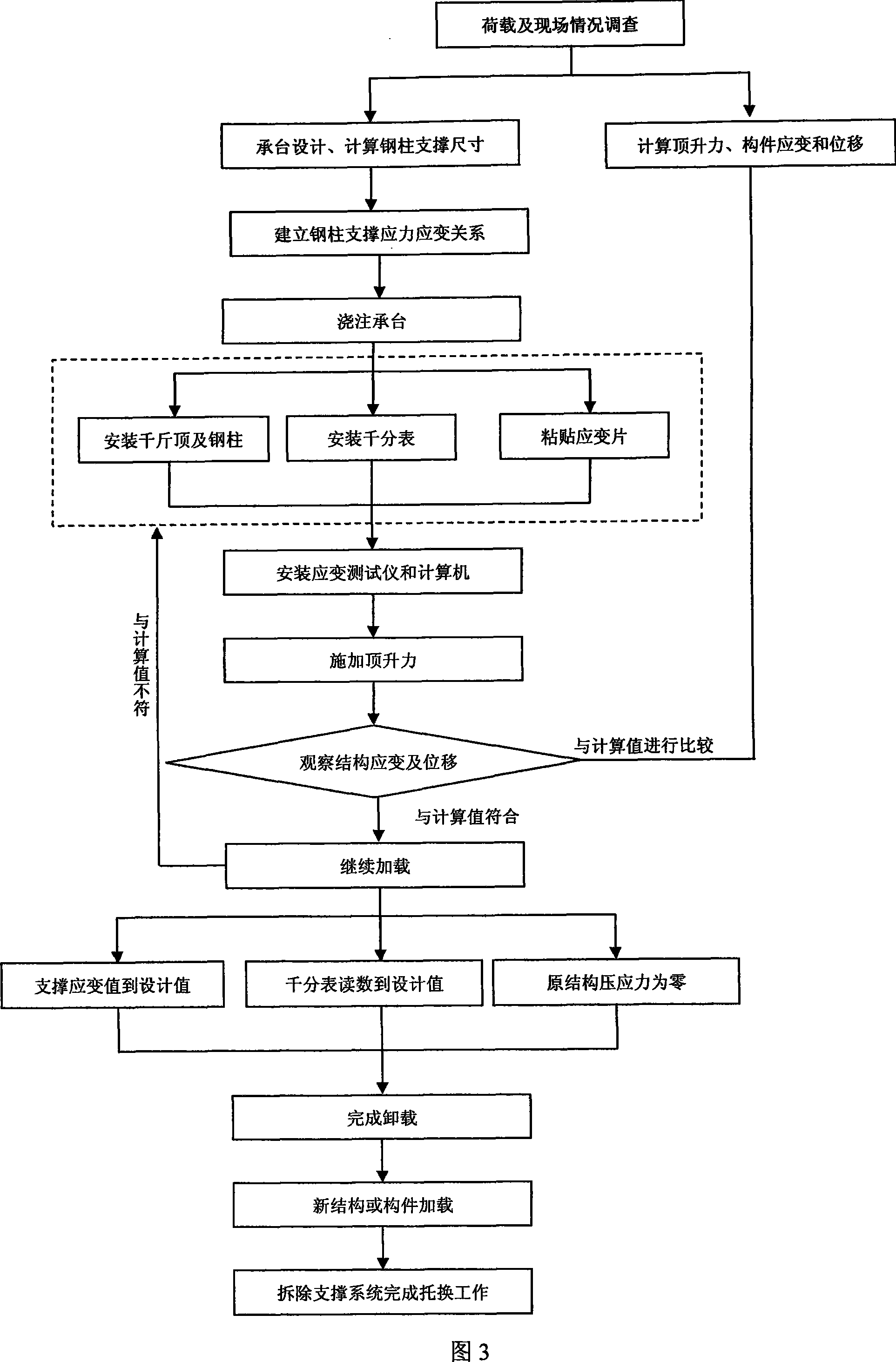

[0030] Take the underpinning of reinforced concrete frame columns as an example: a project is a 19-story frame shear wall structure. Due to construction reasons, the concrete strength of the fifth-story frame column structure does not meet the design requirements of C30. The measured concrete strength is 16.7MPa. At this time, the main body has Completed. The construction unit disagreed with the reinforcement method that left any traces, so it was finally decided to use the replacement method to reinforce the frame column structure. That is to use a reliable support system to remove the low-strength concrete of the frame column and replace it with concrete that meets the design requirements.

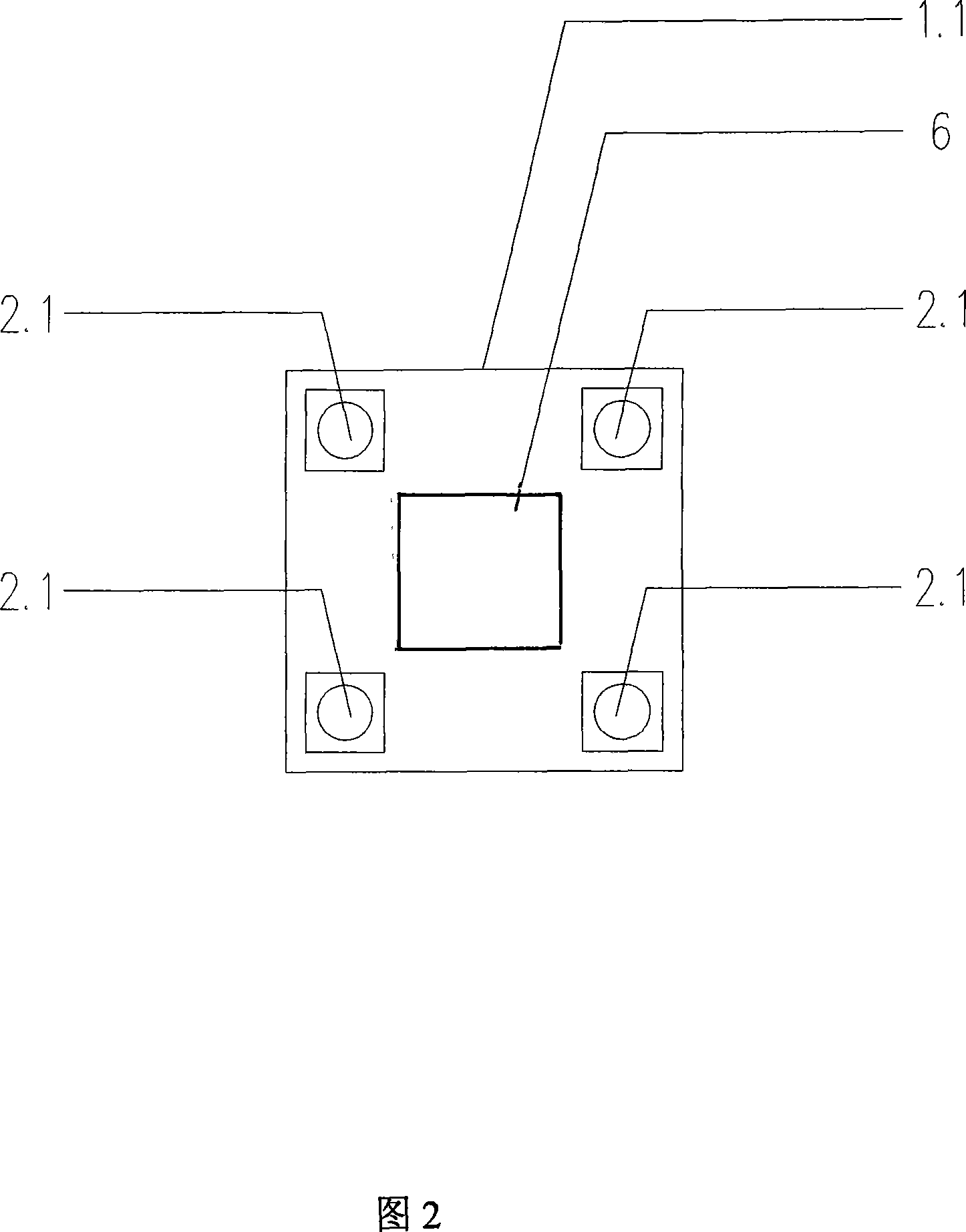

[0031] 1.) Determine the position where the frame column structure needs to be replaced, investigate the cross-sectional size of the structural column, the measured concrete strength, the number and specification of reinforcement, the upper load and distribution, etc.,

[0032] 2.) Dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com