Drilling bit installed with self-inspired pulse resonance jet nozzle

A jet nozzle and drilling bit technology, applied in drill bits, drilling equipment, earthwork drilling and other directions, can solve the problems of insufficient strength, affecting the drilling speed, etc., and achieve the effect of increasing the footage speed and speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

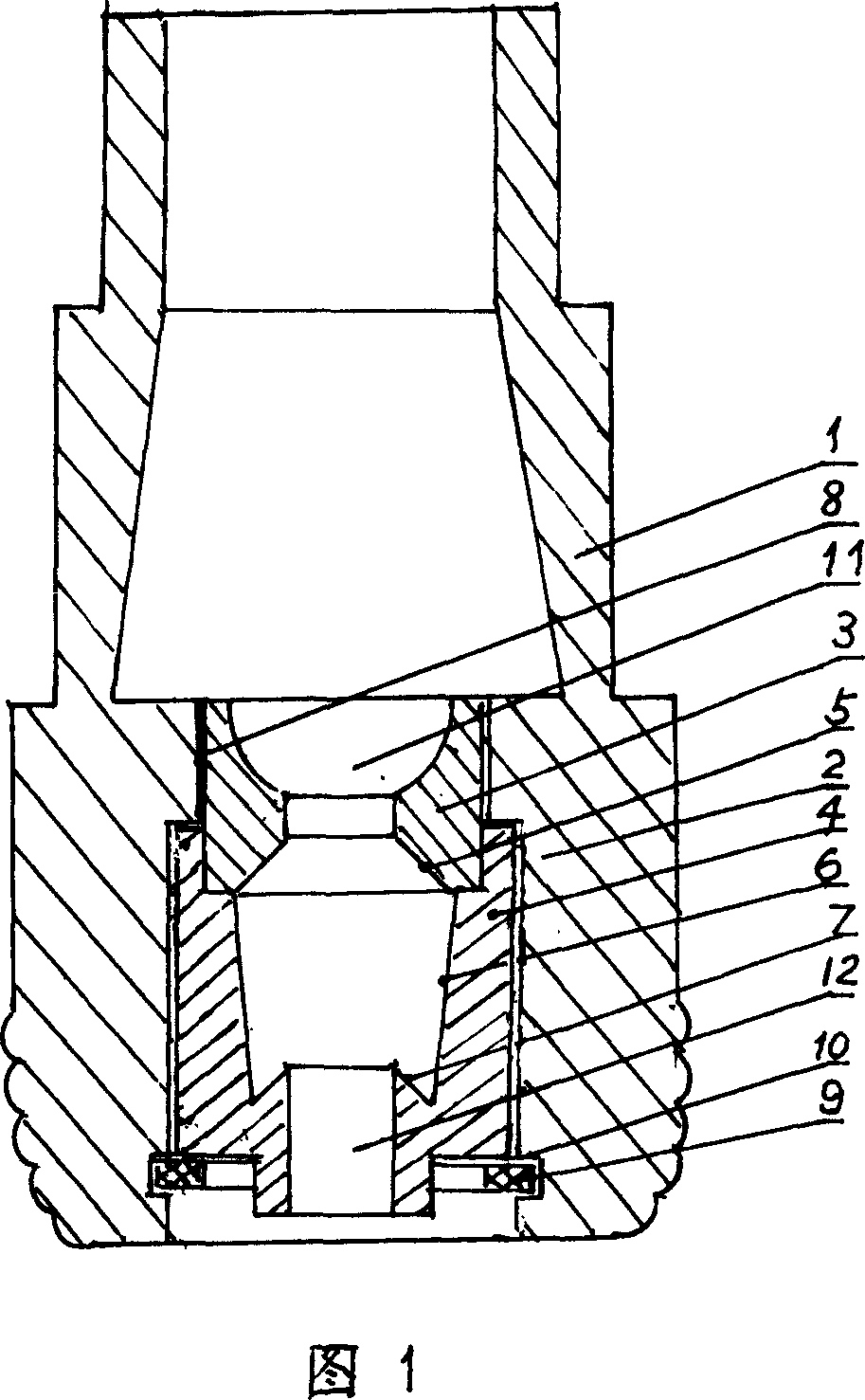

[0010] The specific implementation method is as follows: it includes a drill bit 1 and a self-excited pulse resonance jet nozzle 2; the self-excited pulse resonance jet nozzle 2 includes an inlet nozzle 3 and a reflector 4; the inner hole of the inlet nozzle 3 is divided into three sections. Smaller, the inlet 11 of the upper part of the inner hole is a hole with a large upper part and a smaller cross-section edge, and the inner diameter of the lower end of the hole is equal to the inner diameter of the middle part of the inner hole. The inner diameter of the upper end of the inner hole is equal to the inner diameter of the middle section of the inner hole, and the surface of the conical hole is the upper reflecting surface 5; the inner hole of the reflector 4 is divided into three sections, the inner diameter of the upper section of the inner hole is equal to the outer diameter of the inlet nozzle 3, and the inner diameter of the upper end of the middle section of the inner hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com