Blast furnace blowing bituminous coal grinding machine system and its smoke non-dewatering self-circulation technology

A self-circulation and flue gas technology, applied in the field of blast furnace pulverized coal injection, which can solve the problems of periodic fluctuation of components, inability to quote, and difficulty in flue gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the blast furnace injection bituminous coal mill and its effects according to the present invention will be described in detail as follows .

[0035] Through the description of the specific implementation mode, when the technical means and functions adopted by the present invention to achieve the predetermined purpose can be obtained a deeper and more specific understanding, but the accompanying drawings are only for reference and description, and are not used to explain the present invention be restricted.

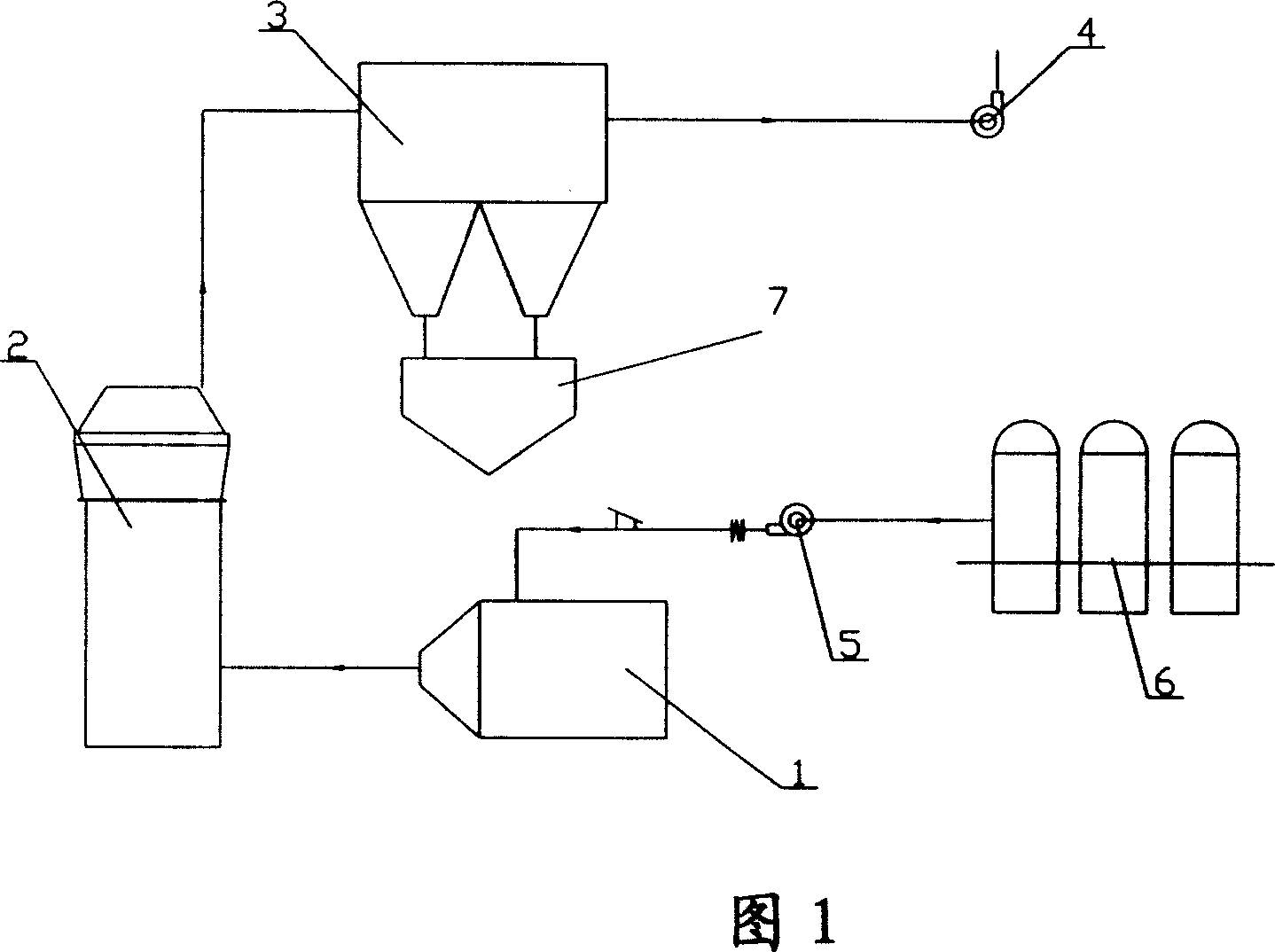

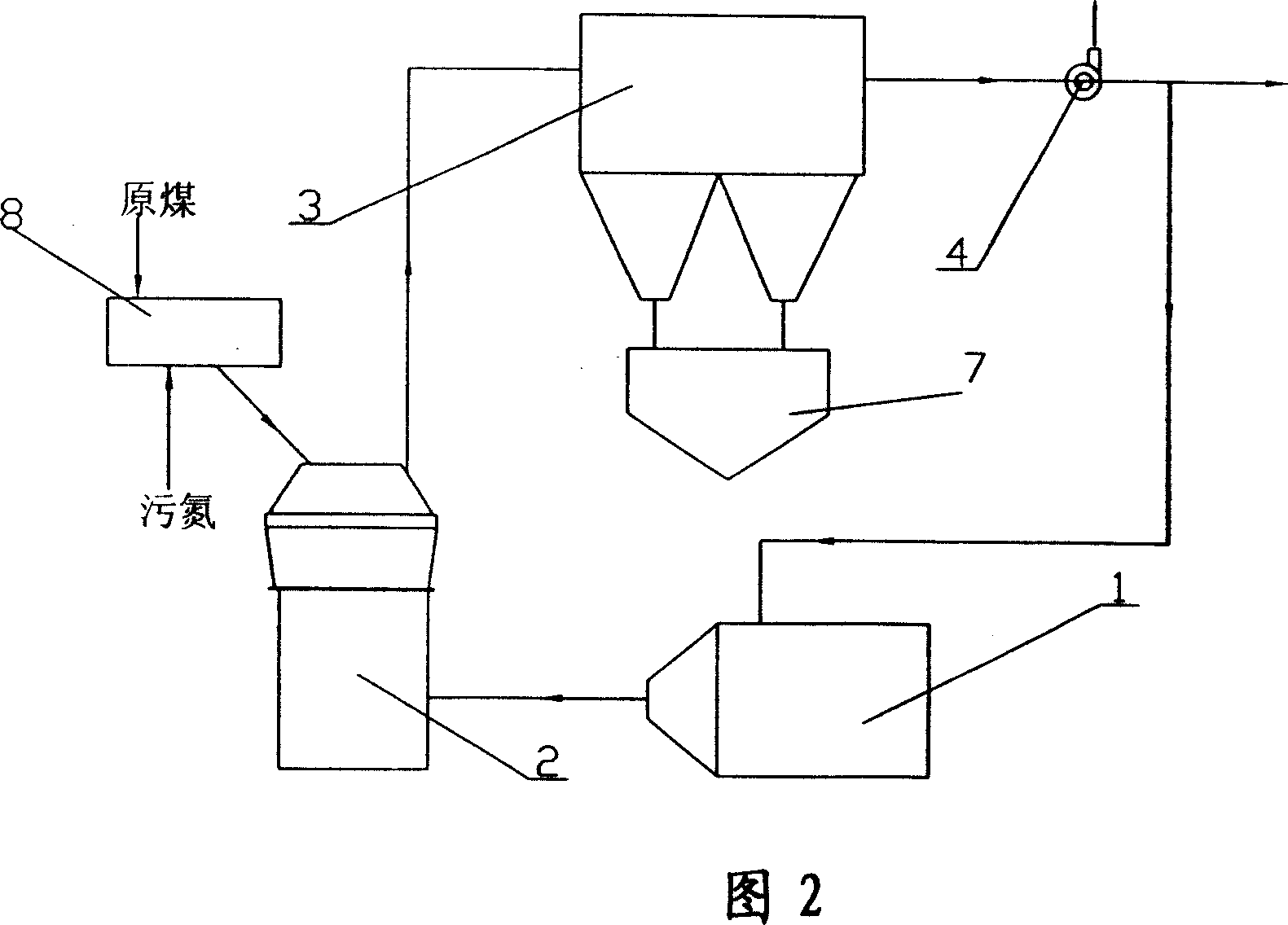

[0036] Please refer to Fig. 2, which shows a structural block diagram of the coal-injection pulverization flue gas circulation system of the present invention, which system includes a mill 2, a bag powder collector 3, a heating furnace 1 and a closed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com