Monorail pulley unhooking system

A pulley and detachment technology, which is applied in the direction of skidways, entertainment, entertainment devices, etc., can solve problems such as detachment, achieve the effect of simple structure, stable and reliable detachment, and meet the requirements of safety regulations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

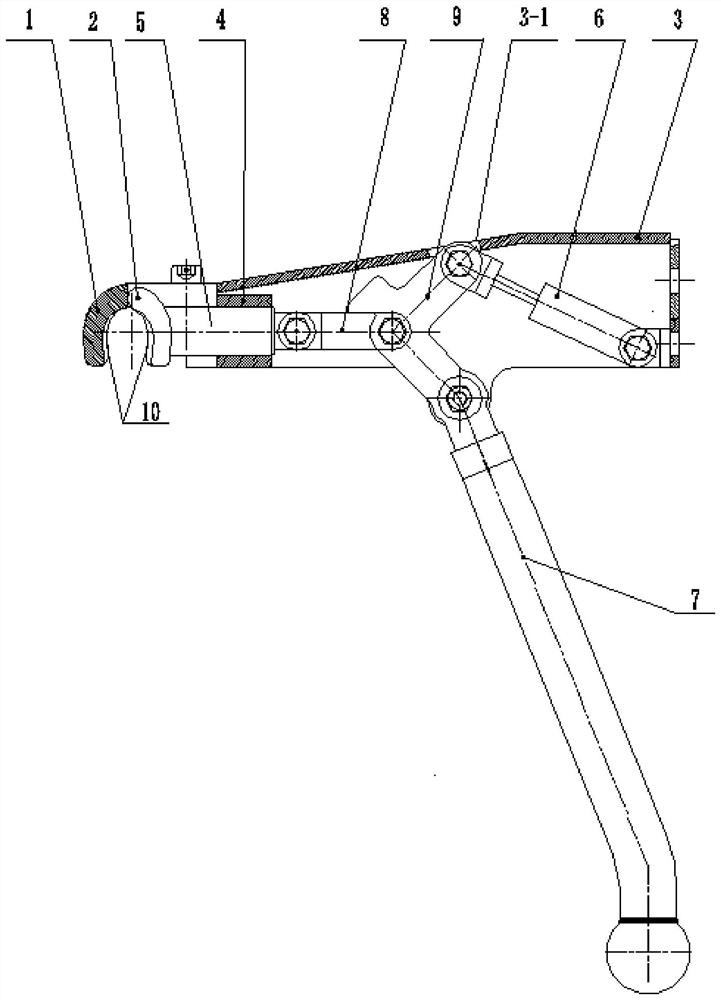

[0015] Specific implementation mode one: combine figure 1 Describe this embodiment mode, a kind of monorail pulley decoupling system described in this embodiment mode comprises fixed pinch nozzle 1, dynamic pinch nozzle 2, driving mechanism, tractor carrier 3, and fixed pincer nozzle 1 is installed on the left side of tractor carrier 3 At the side opening end, the driving mechanism is located in the carrier body 3 of the tractor, the movable pinch mouth 2 and the fixed pinch mouth 1 form an inverted U-shaped jaw, and the drive assembly is connected with the dynamic pinch mouth 2 .

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 Describe this embodiment, the driving assembly described in this embodiment includes a mounting seat 4, a connecting body 5, a chain rod assembly, an air pressure push rod 6 and a pulling rod 7, and the mounting pin 4 is located at the left open end of the tractor carrier 3 , the connecting body 5 is inserted in the mounting seat 4, one end of the connecting body 5 is connected with the moving jaw 2, the other end of the connecting body 5 is connected with the piston rod of the air pressure push rod 6 through the chain rod assembly, and the pulling rod 7 is connected with the chain rod assembly connection.

[0017] Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 Describe this embodiment, the chain rod assembly described in this embodiment includes a first chain rod 8 and a second chain rod 9, one end of the first chain rod 9 is hinged to the connecting body 5, and the other end of the first chain rod 8 is connected to the second Chain bar 9 is connected.

[0019] The other components are the same as those in Embodiment 1 or 2 in terms of connections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com