Column fully moving grinding machine

A full-moving, column technology, applied in the direction of grinding bed, grinding machine parts, grinding frame, etc., can solve the problem that the single-column grinding machine cannot move in the X direction, and achieve stability and cutting rigidity. Improved balance and anti-vibration performance, improved grinding surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

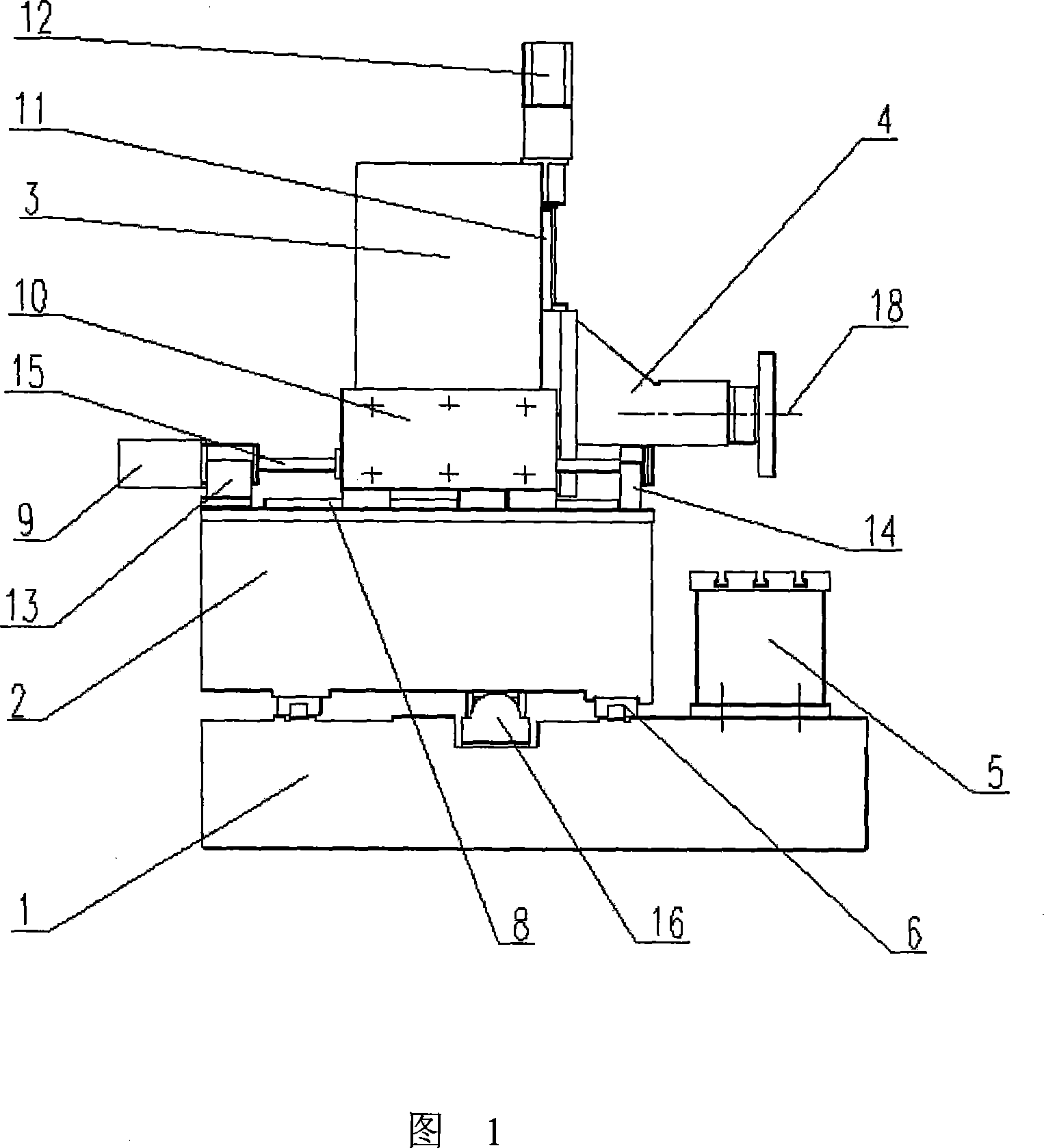

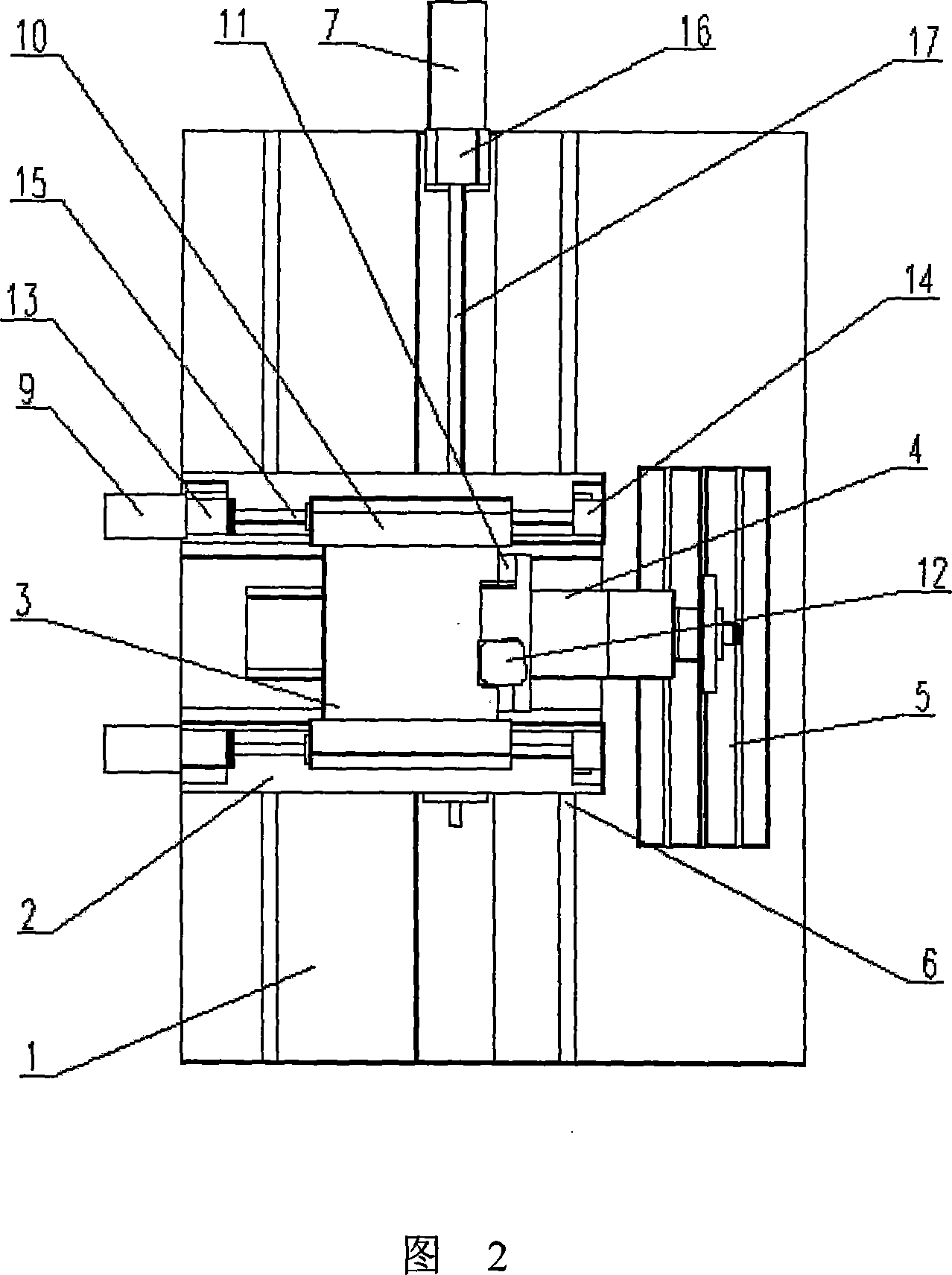

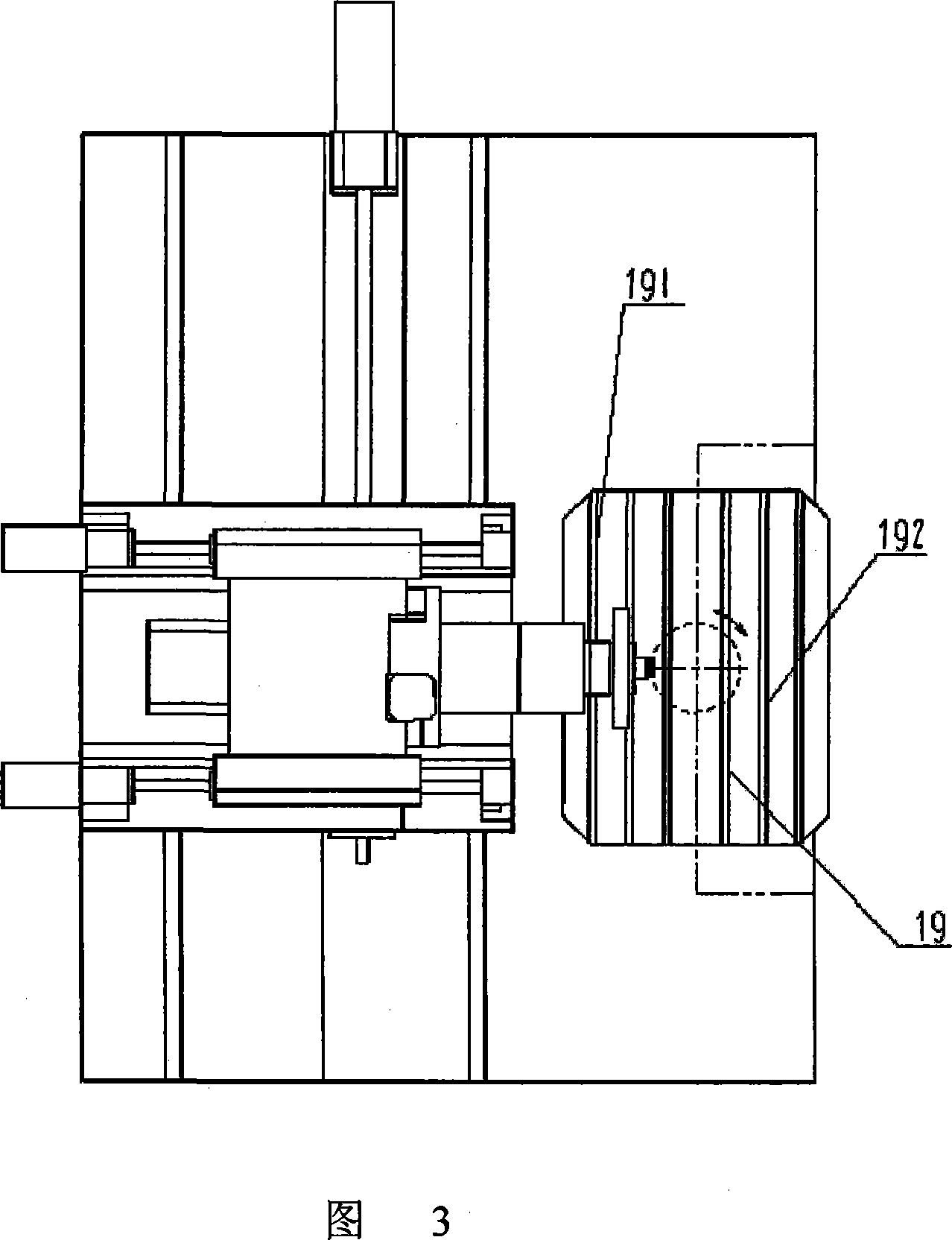

[0019] Embodiment: as shown in Fig. 1 and Fig. 2, the column full-moving grinder, the bed 1 is in the shape of a box-type flat plate, the dimensions of length × width × height: 3200 × 2150 × 427 (mm), and the material is HT250; X-direction movement is installed on it Guide rail 6, two linear rolling guide rails, width × length: 55 × 2880 (mm); X-direction drive mechanism 7 has a ball screw pair 17, specification: ¢50 × 2350 (mm), with casting bracket 16 and X-direction servo The motors are connected in 7 phases, the power / torque of the servo motor 7 is 6.5kW / 41.5Nm, and the maximum feed speed in the X direction is 15000mm / min, which can meet the technical requirements of the main grinding movement. The carriage 2 is U-shaped, the lower part is equipped with a guide rail slider matching the X-direction moving guide rail 6, and the upper part is equipped with a Z-direction moving guide rail 8 and a Z-direction biaxial drive mechanism 9; two linear rolling guide rails, width × len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com